Golf Club Engraving with Laser Machines: A Comprehensive Guide

Introduction

In recent years, golf club engraving has become a popular way to personalize and customize golf equipment. This trend is fueled by advancements in laser engraving technology, which offer precise, durable, and high-quality engravings. Here, we provide a comprehensive guide on using laser engraving machines for golf club engraving, focusing on laser technology, machine specifications, materials, safety, and best practices.

Laser Engraving Technology and Its Applications

The technology behind laser engraving is both fascinating and highly versatile. It uses a focused beam of light to engrave material surfaces, offering exactitude and finesse that is difficult to achieve with traditional methods. Laser engraving is applicable across a broad range of industries including jewelry, automotive, and sports equipment, particularly golf club engraving.

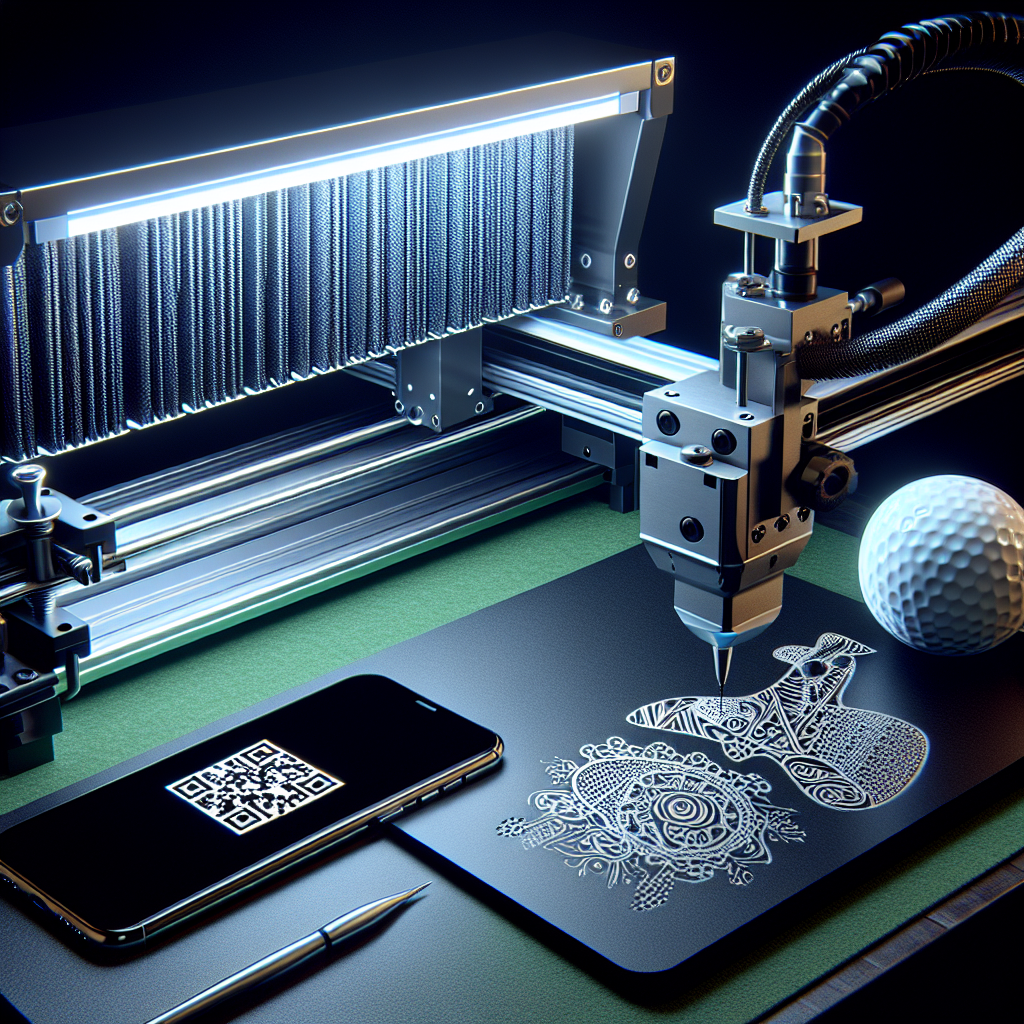

Laser engraving machines like the xTool S1 Enclosed Diode Laser Cutter are instrumental in this realm, capable of producing intricate designs and texts on various materials with high precision.

Machine Specifications and Features

When choosing a laser engraving machine for golf club engraving, several specifications and features are crucial:

- **Power**: The power of the laser determines the types of materials the machine can engrave and the speed of production. Typically, for golf club engraving, a diode laser with a modest power output suffices.

- Precision and Speed: Look for machines with high DPI (dots per inch), indicating fine detail capability, as well as sufficient speed to meet production needs.

- **Software Compatibility**: Modern laser machines often come with intuitive software compatible with various design formats, but checking the ease of integration with your existing systems is important.

- Enclosure and Safety Features: Proper housing is critical for a safe working environment, as are features like emergency stops and laser shields.

Material Compatibility

A key factor in selecting a laser engraving machine is its compatibility with the materials used in golf club engraving. Golf clubs are typically made from metals such as steel and titanium, which require specific laser settings for optimal engraving quality without damaging the club.

Many modern laser machines, including the xTool S1 Enclosed Diode Laser Cutter, are versatile enough to handle a wide range of materials, adding to their utility for professional and hobbyist engravers alike.

Safety Considerations

While laser engraving offers immense precision and efficiency, it also brings safety concerns that must be addressed:

- **Eye Safety**: Direct exposure to laser beams can cause severe eye damage. An enclosed design, like that of the xTool S1, minimizes this risk.

- Ventilation: The engraving process can produce fumes or dust, necessitating adequate ventilation or a fume extraction system.

- **Electrical Safety**: Ensure that the electrical components are in good condition and the machine is grounded properly to prevent accidents.

Industry Best Practices

Maintaining best practices is essential for successful golf club engraving outcomes. Experienced engravers recommend routine calibration of the machine for consistent quality and regular cleaning of optical elements to preserve performance.

Furthermore, always conduct a test run on scrap material to fine-tune settings before beginning a new project, ensuring optimal results without risking high-value items.

Cost-Benefit Analysis

Considering the cost versus the benefits of laser engraving machines is important for any business or individual. While initial costs for a high-quality machine can be considerable, the efficiency and precision they offer can lead to significant returns through enhanced product personalization and reduced labor costs.

A durable and versatile machine like the xTool S1 Enclosed Diode Laser Cutter supports a variety of applications beyond golf club engraving, expanding potential revenue streams.

Maintenance Tips

Proper maintenance ensures the longevity and performance of your laser engraving machine. Key tips include:

- Regularly inspecting the machine for loose parts or wear.

- Cleaning the work area to prevent debris build-up.

- Replacing worn components promptly.

- Updating software to incorporate the latest technological advancements.

These practices keep your machine operating at peak efficiency.

Project Ideas and Tutorials

Laser engraving offers endless creative possibilities for golf club customization. Consider these project ideas:

- Name and Logo Customization: Personalize golf clubs with names or logos for gifts or corporate events.

- Engraved Patterns: Add decorative patterns to enhance the aesthetic appeal of golf clubs.

- QR Code Engraving: Incorporate QR codes that link to digital content or profiles, adding an interactive element.

Online tutorials can guide you through the design and engraving process, helping you maximize the potential of your equipment.

Conclusion

The union of modern golf club engraving and advanced laser technology creates a realm of possibilities for customization, artistry, and business growth. With machines like the xTool S1 Enclosed Diode Laser Cutter offering flexibility, precision, and efficiency, engaging in engraving projects has never been more accessible or rewarding.

By understanding the specifications, safety measures, best practices, and project ideas discussed here, both new and seasoned engravers can enhance their craft and deliver extraordinary results.