Hand Held Laser Cutter for Steel: Unleashing Precision and Creativity

Introduction

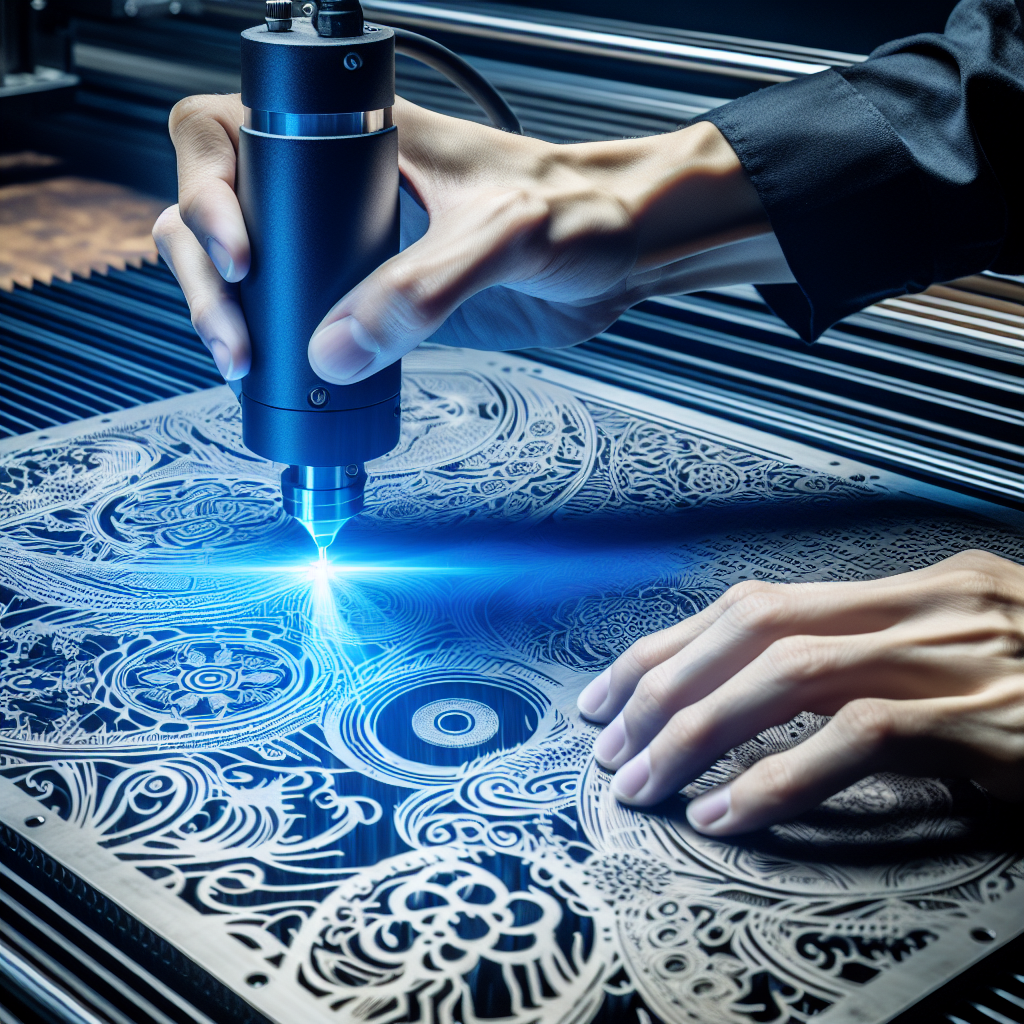

In recent years, laser engraving and cutting technology have surged in popularity, thanks to advancements that make these tools more portable, precise, and versatile. Among these innovations, the hand held laser cutter for steel stands out as an impressive game-changer. With its robust functionality, ease of use, and adaptability, this device transforms crafting, prototyping, and even industrial applications. In this article, we’ll explore what makes this powerful tool a must-have, how it works, and what you need to consider before diving into the world of laser engraving and cutting.

Laser Engraving Technology and Applications

At its core, a handheld laser cutter utilizes focused laser beams to carve, etch, or cut materials like steel. The precision and depth control provided by these machines are unmatched, allowing for both intricate designs and robust industrial cuts. People often associate laser engraving with decorative applications like personalized gifts or signage. However, a hand held laser cutter for steel opens up far more opportunities, including:

- Industrial prototyping and manufacturing

- Architectural model-making

- Medical device customization

- Steel fabrication for automotive and aerospace industries

- Crafting custom tools or household hardware

The breadth of this technology continues to expand, especially as engineers and hobbyists push the boundaries of what’s possible with laser cutters.

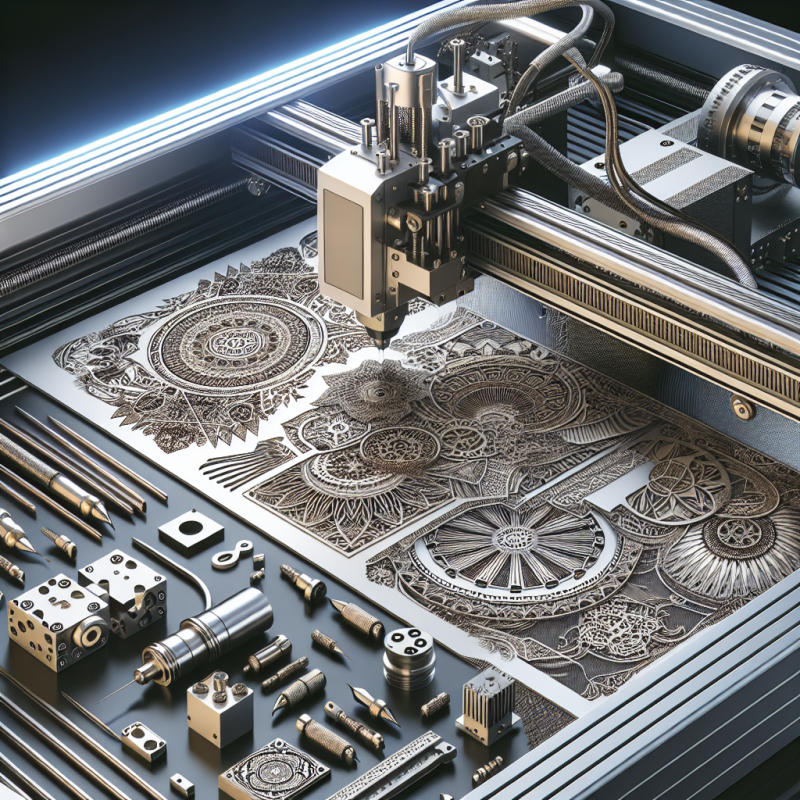

Key Features of a Hand Held Laser Cutter for Steel

When it comes to portable laser cutting solutions, the hand held laser cutter for steel is a standout product. Let’s delve into some of its key features that make it unique and highly sought after:

- Portability: Compact and lightweight, handheld laser cutters are easy to move around, making them perfect for on-site tasks or small workshops.

- High-Powered Laser: The 20W Fiber Diode Laser featured in machines like the LaserPecker LP5 ensures uniform cuts on dense materials such as steel, while maintaining precision.

- Smart Functionality: With app integration and intuitive controls, even novice users can achieve professional-grade results.

- Efficient Cooling System: This prevents the machine from overheating, ensuring longer operating times and extending its lifespan.

- Sustainability: Using minimal power compared to traditional cutting tools, laser cutters are kinder to the environment without compromising performance.

These features make the machine not only powerful but also user-friendly, catering to a broad range of tasks and industries.

Material Compatibility

One of the frequently asked questions is, “What materials can you work on with a handheld laser cutter?” A hand held laser cutter for steel, as the name suggests, excels at cutting metal, including steel. However, it’s also compatible with numerous other materials:

- Aluminum alloys

- Titanium

- Plastics (such as acrylic and PVC)

- Wood

- Leather

- Glass (for engraving purposes)

Being able to work on such a wide array of materials allows users to transition seamlessly between projects, whether they are focused on heavy-duty industrial tasks or creative crafts.

Safety Considerations

While the technologies in handheld laser cutters are designed to be safe, it’s vital to follow best practices to protect yourself and your surroundings. Here are some crucial safety tips:

- Wear appropriate safety glasses: This protects your eyes from harmful laser radiation.

- Ventilate the workspace: Cutting certain materials like plastics can release fumes.

- Secure the material being cut: This reduces the risk of accidents or irregular cuts.

- Avoid direct contact: Ensure the laser beam does not come into contact with your skin or reflective surfaces.

- Regular maintenance: Inspect the machine and ensure it is in optimal working condition before each use.

Are handheld laser cutters safe for beginners? The answer is a resounding yes – as long as users adhere to these guidelines.

Cost-Benefit Analysis

Investing in a hand held laser cutter for steel might feel pricey upfront, but when you delve into the long-term benefits, the decision becomes clearer:

- Precision and Efficiency: These factors dramatically reduce waste materials and errors, saving costs over time.

- Versatility: From steel to acrylic and wood, a single machine can serve hundreds of purposes.

- Time-saving: The speed and accuracy of laser cutters minimize production timelines.

- Durability: Modern handheld laser systems are built to last for years with minimal upkeep.

While the upfront cost may seem significant, the versatility and durability of the device more than justify the investment.

Maintenance Tips for Longevity

Proper maintenance ensures your laser cutter remains in excellent condition and performs optimally over its lifespan. Here are some essential tips:

- Regularly clean the laser lens to maintain precise beam focusing.

- Check for software updates to ensure compatibility and functionality.

- Inspect and tighten all screws and mounts periodically.

- Store the device in a clean, dry area to prevent dust accumulation or corrosion.

- Schedule professional servicing as recommended by the manufacturer.

With these steps, you’ll enjoy uninterrupted operations and consistently superior outcomes.

Project Ideas and Tutorials

If you’re new to the world of handheld laser cutters or simply looking for inspiration, here are some project ideas to get started:

- Design unique steel keychains or nameplates for personal use or gifting.

- Create industrial prototypes for machinery components.

- Engrave patterns on stainless steel kitchenware for decorative appeal.

- Cut custom steel parts for DIY furniture or automotive projects.

- Laser-engrave intricate designs for jewelry or art pieces.

Many manufacturers also provide online tutorials and resources to help you make the most of your device. It’s a world of creativity and precision waiting to be explored!

Conclusion

The hand held laser cutter for steel is far more than just a piece of machinery; it’s a door to unparalleled precision and creative freedom. Whether you’re looking to personalize items, take on heavy-duty industrial tasks, or start an engraving business, this tool empowers you to take your ideas to the next level. With proper maintenance, thoughtful safety measures, and an eye for innovation, the potential applications of these laser cutters are virtually limitless.

So, what will you create with your handheld laser cutter? Dive into this exciting realm today and experience the brilliant fusion of art, engineering, and technology!