Laser Aluminium Engraving: Precision and Versatility in Metalworking

Laser aluminium engraving has become a cornerstone of modern metalworking, offering unparalleled precision and versatility. Whether you’re creating intricate designs for industrial components or adding personalized touches to consumer products, this technology is revolutionizing the way we work with metals. This article delves into the intricacies of laser aluminium engraving, its applications, benefits, and considerations for those looking to adopt this cutting-edge technique.

The Basics of Laser Engraving on Aluminium

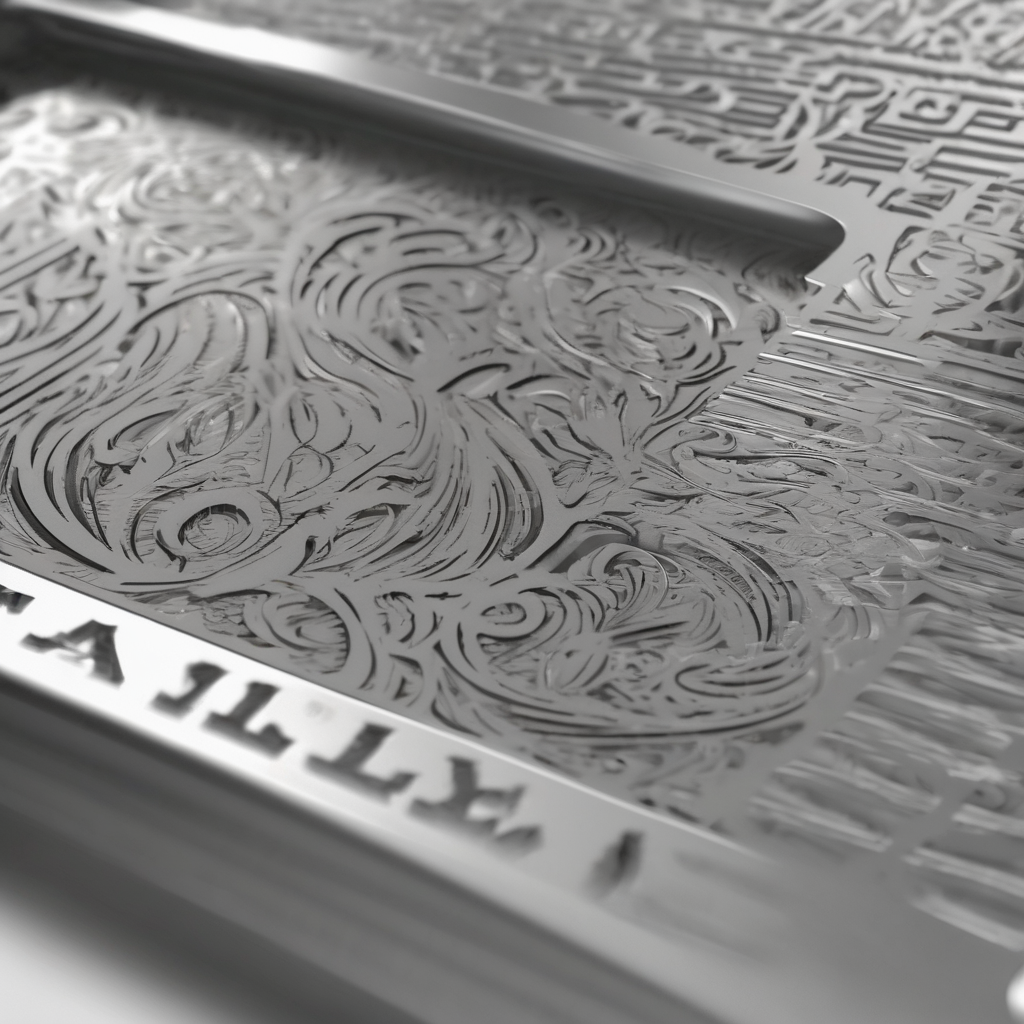

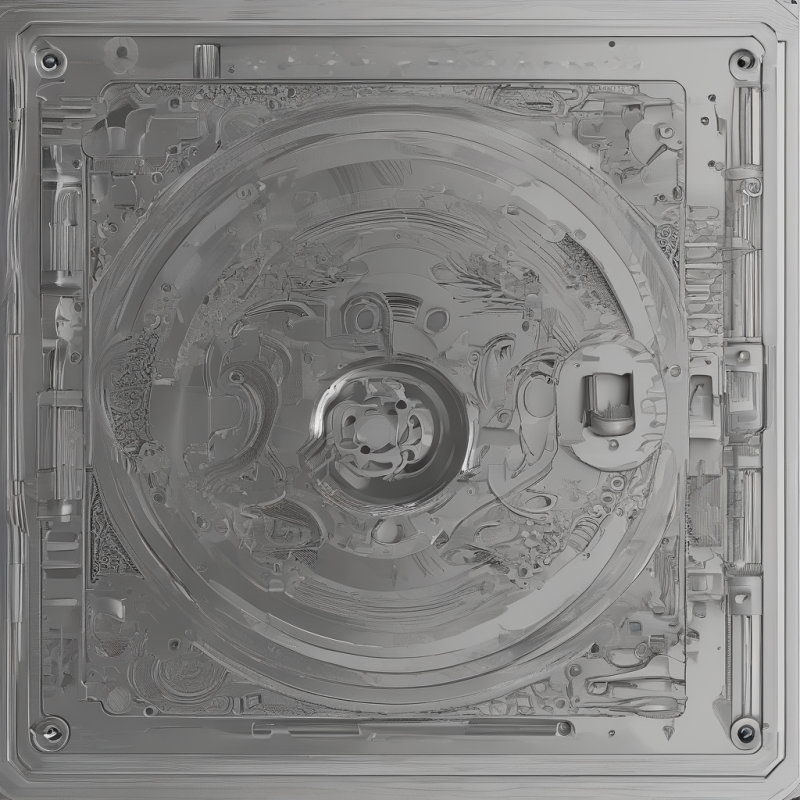

Laser engraving is a process that uses high-powered lasers to etch designs or text onto the surface of materials. When it comes to aluminium, this method is particularly effective due to the material’s reflective properties and thermal conductivity. The laser beam melts or vaporizes the material, creating precise and permanent markings.

One of the key advantages of laser aluminium engraving is its ability to work on both flat and curved surfaces. This makes it ideal for a wide range of applications, from decorative items like engraved trophies to industrial parts requiring detailed serial numbers. The process is also highly efficient, allowing for rapid production of custom designs without the need for physical tools or molds.

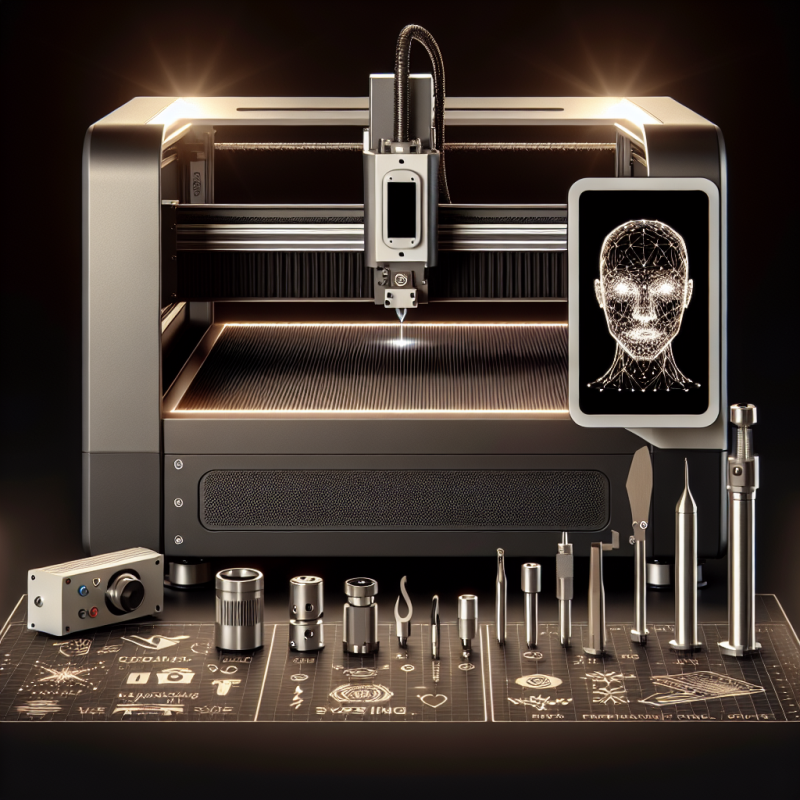

To achieve optimal results, it’s essential to select the right equipment. For instance, the machine is designed specifically for metalworking, ensuring high-quality engravings with minimal setup time. These machines are equipped with advanced software that allows users to create and modify designs directly on the interface.

Applications of Laser Aluminium Engraving

The applications of laser aluminium engraving are vast and varied. Here are some of the most common uses:

- Customized Decorative Items: From engraved nameplates to ornamental pieces, laser engraving adds a touch of elegance and personalization.

- Industrial Components: Serial numbers, part codes, and barcodes can be permanently etched onto aluminium parts for traceability and identification.

- Automotive Parts: Engraving is used to mark engine components, dashboard panels, and other automotive parts with precision and clarity.

- Jewelry Making: Laser engraving allows for intricate designs on aluminium jewelry pieces, such as pendants and rings.

The versatility of laser aluminium engraving makes it a valuable tool across industries. Whether you’re working in manufacturing, design, or craftsmanship, this technology offers a reliable and efficient solution for creating detailed markings.

Considerations for Laser Aluminium Engraving

While laser aluminium engraving is a powerful technique, there are several factors to consider when planning your project:

- Material Thickness: Thicker aluminium sheets may require higher-powered lasers or multiple passes to achieve the desired depth.

- Laser Speed and Power: Adjusting these settings is crucial for maintaining consistent results, especially when working on complex designs.

- Surface Finish: The finish of the aluminium surface can affect the visibility of engravings. Pre-treating the material may be necessary in some cases.

- Environmental Factors: Proper ventilation and safety precautions are essential when working with lasers, as they generate fumes and particles during the engraving process.

By addressing these considerations, you can ensure that your laser aluminium engraving projects meet the highest standards of quality and safety. For example, using the machine can help you maintain precision and efficiency while minimizing the risk of errors.

Challenges in Laser Aluminium Engraving

Despite its many advantages, laser aluminium engraving does present some challenges that must be addressed:

- Reflectivity of Aluminium: Aluminium’s high reflectivity can sometimes cause the laser beam to scatter or lose focus. Specialized optics and cooling systems are often required to mitigate this issue.

- Temperature Control: The thermal conductivity of aluminium means that excessive heat can lead to warping or discoloration of the material. Proper cooling techniques must be employed during engraving to prevent these issues.

- Design Complexity: While laser engraving is capable of producing highly detailed designs, overly complex patterns may require additional passes or adjustments to achieve the desired results.

To overcome these challenges, it’s important to invest in high-quality equipment and software. For instance, the machine is designed with advanced cooling systems and precision optics to ensure optimal performance on reflective materials like aluminium.

The Future of Laser Aluminium Engraving

As technology continues to evolve, laser aluminium engraving is poised to become even more accessible and versatile. Innovations in laser cutting software and machine design are making it easier than ever for businesses and individuals to take advantage of this powerful tool.

In the coming years, we can expect to see increased adoption of laser engraving in industries ranging from aerospace to consumer electronics. The ability to create highly detailed and durable markings on aluminium components will be a key factor in driving innovation across these sectors.

Frequently Asked Questions

Q: Can I use the same laser machine for engraving different metals?

A: While many laser machines are capable of working with multiple materials, it’s important to select a machine specifically designed for metalworking if you plan to focus on aluminium or other reflective metals.

Q: How long does it take to learn laser aluminium engraving?

A: With the right equipment and software, users can typically become proficient in laser aluminium engraving within a few weeks. Training resources and tutorials are widely available to help you get started.

Q: Is laser aluminium engraving cost-effective for small-scale projects?

A: Yes, modern laser machines like the laser aluminium engraving machine are designed to be user-friendly and cost-effective, even for small-scale projects.

Conclusion

Laser aluminium engraving is a transformative technology that is reshaping the way we work with metals. Its precision, versatility, and efficiency make it an invaluable tool for businesses and individuals alike. By understanding the basics of this process, its applications, and the considerations involved, you can unlock new possibilities in your metalworking projects.

If you’re ready to take the next step into the world of laser aluminium engraving, consider investing in a high-quality machine like the system. With its advanced features and user-friendly design, it’s the perfect choice for achieving exceptional results in your metalworking projects.

Whether you’re creating custom decorative items or precision-engineered components, laser aluminium engraving offers a reliable and efficient solution for all your marking needs. Embrace this innovative technology today and elevate your metalworking projects to new heights!