Laser CO2 Cutting Machine: Features and Applications Guide

Introduction

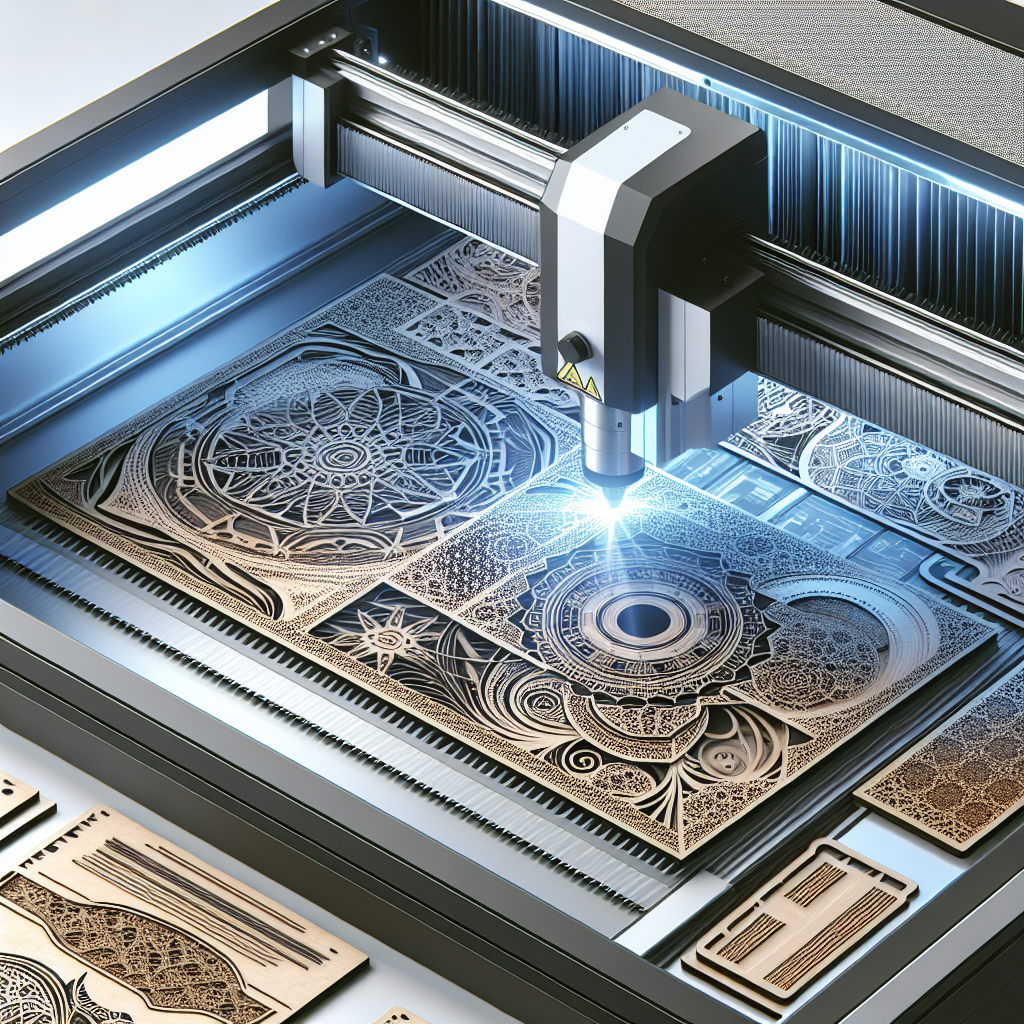

In the fast-evolving world of manufacturing and crafting, laser cutting and engraving have revolutionized how we create and produce. Among the various technologies available, the laser co2 cutting machine stands out for its precision and versatility. This article delves into the intricacies of laser CO2 cutting machines, examining their technology, applications, and benefits to provide a comprehensive guide for potential users.

Understanding Laser CO2 Cutting Technology

At the heart of the laser co2 cutting machine is the CO2 laser, a gas laser that employs a mixture of carbon dioxide, nitrogen, hydrogen, and helium. When electrically stimulated, these gases emit a beam of infrared light. This beam is focused and directed onto materials to cut or engrave intricate details. The precision and power of a CO2 laser make it suitable for a wide range of applications, from hobbyist projects to industrial manufacturing.

Machine Specifications and Features

The laser co2 cutting machine offers various specifications that contribute to its efficiency and performance. Typically, these machines have a power range between 30 to 150 watts or more, determining their cutting ability and speed. The size of the cutting bed, often ranging from 12×20 inches to 48×96 inches, dictates the scale of the material it can handle. Moreover, the software compatibility and connectivity options, such as USB and Ethernet, enhance their usability.

Material Compatibility

One of the significant advantages of using a laser co2 cutting machine is its ability to work with a variety of materials. It performs exceptionally well on non-metallic materials such as wood, acrylic, glass, leather, fabric, and certain plastics. However, special considerations are needed when working with materials like PVC, as they release harmful gases. Understanding material compatibility is crucial for optimal results and user safety.

Safety Considerations

Safety remains a paramount concern when operating high-power gadgets like the laser co2 cutting machine. Proper ventilation is essential to dispel fumes generated during cutting, especially when working with plastics. Additionally, operators should always wear appropriate eye protection, as exposure to laser beams can cause severe damage. Machines should be housed in well-secured enclosures to prevent accidental exposure.

Industry Best Practices

When incorporating a laser co2 cutting machine into your workflow, adhering to industry best practices ensures productivity and longevity of the equipment. Regular training on software and machine operation allows the operator to exploit the full potential of the device. Consistent calibration and alignment checks optimize precision and performance. Additionally, keeping a log of maintenance schedules and parts replacement ensures the machine operates at peak efficiency.

Cost-Benefit Analysis

Investing in a laser co2 cutting machine involves a thoughtful cost-benefit analysis. While the initial purchase and setup can be substantial, the long-term gains in productivity and diversity of projects are immense. These machines reduce manual labor and minimize waste while offering unparalleled precision. For businesses, the ability to create customized items and prototypes in-house can significantly lower production costs and time-to-market.

Maintenance Tips

To ensure your laser co2 cutting machine remains in optimal condition, regular maintenance is crucial. Here are some key maintenance tips:

- Clean the lens and mirrors regularly to prevent residue build-up that can diminish laser efficiency.

- Ensure the cooling system is functioning properly to prevent overheating.

- Check belts and other moving parts for wear and replace as necessary.

- Keep the cutting bed clean to ensure smooth material movement and precision.

Project Ideas and Tutorials

Using a laser co2 cutting machine opens up a world of creativity and opportunities. Here are some project ideas to get started:

- Create intricate wood inlays for furniture or cabinetry.

- Design custom laser-cut jewelry using acrylic or wood.

- Produce personalized gifts, such as engraved glassware or leather wallets.

- Tutorials for beginners can cover basic shapes and transitions to complex patterns over time.

Questions About Laser Engraving Machines

When considering a laser co2 cutting machine, several questions might arise:

- How does a CO2 laser compare to other types of lasers in terms of precision and material compatibility?

- What are the crucial safety measures to ensure while operating the machine?

- How frequently should the machine be serviced to maintain peak performance?

- What software is essential for designing and converting images for laser cutting?

Conclusion

The laser co2 cutting machine is an indispensable tool for anyone involved in detailed crafting or manufacturing. Whether you are a hobbyist, startup, or large-scale producer, this technology extends your creative and practical capabilities while ensuring efficiency and precision. By understanding the parameters of operation and adhering to safety and maintenance protocols, users can maximize the potential of their cutting and engraving projects, enhancing both productivity and innovation.