Laser Cutter Balsa Laser Engraving Machines

Introduction to Laser Engraving Technology and Applications

Laser engraving technology has revolutionized the world of precision cutting and intricate design applications. Utilizing high-energy laser beams, these machines can create stunningly detailed engravings and cuts on a wide variety of materials. One specific niche where laser cutters excel is in the processing of balsa wood, a lightweight yet strong material favored by artists, hobbyists, and professionals alike. In this article, we will delve into the technology, applications, specifications, and best practices associated with laser cutter balsa laser engraving machines.

Laser Engraving Technology

Laser engraving machines work by focusing a high-intensity laser beam onto the surface of a material. The beam vaporizes or alters the material, leaving behind a precise and detailed image or cut. This process is non-contact, meaning there is no physical wear and tear on the machine or the material, resulting in high precision and repeatability.

Laser engraving technology offers several advantages over traditional methods such as mechanical routing or hand carving. It is faster, more accurate, and capable of producing far more intricate designs. Additionally, laser engraving does not require the use of tools that can become dull over time, ensuring consistent quality from the first to the last piece produced.

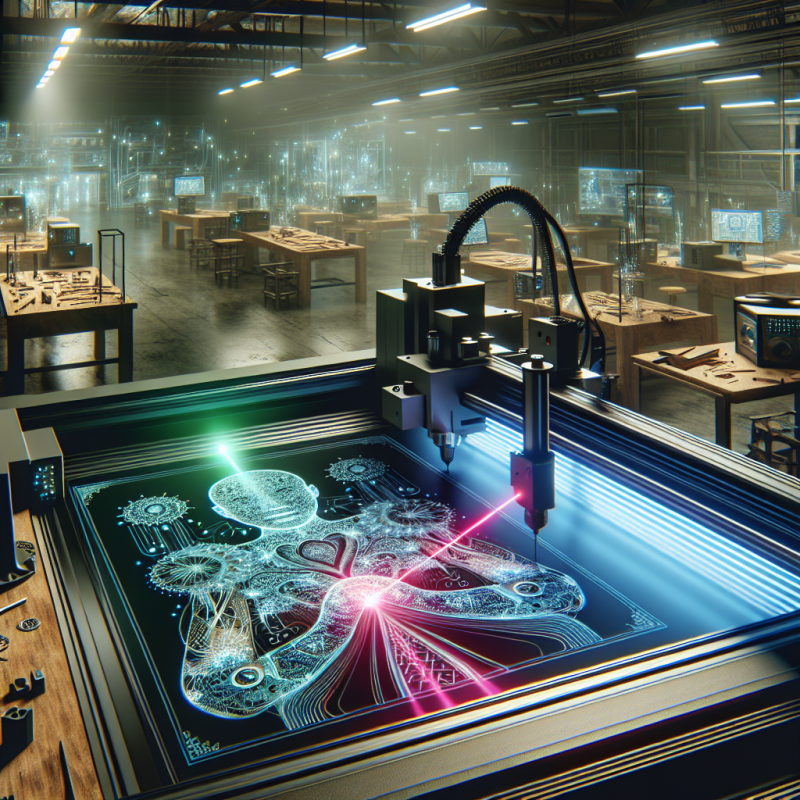

Applications of Laser Cutter Balsa Laser Engraving Machines

Balsa wood is a favorite material for laser cutting and engraving due to its lightweight, soft texture, and ease of manipulation. It is widely used in model building, particularly in aircraft and boat construction, where its low density and high strength-to-weight ratio are advantageous. Laser cutter balsa machines enable creators to transform this versatile material into intricate works of art.

- Model Building: Detailed architectural models, miniature landscapes, and toy vehicles can all benefit from the precision of laser cutting.

- Art and Craft: Artists and craftspeople use laser cutters to create intricate patterns, textures, and designs on balsa wood panels and sculptures.

- Educational Projects: Schools and universities often use laser cutters for educational purposes, teaching students about design, engineering, and material properties through hands-on projects.

- Prototyping: Designers and engineers rely on laser cutters for rapid prototyping, allowing them to quickly iterate and refine their ideas.

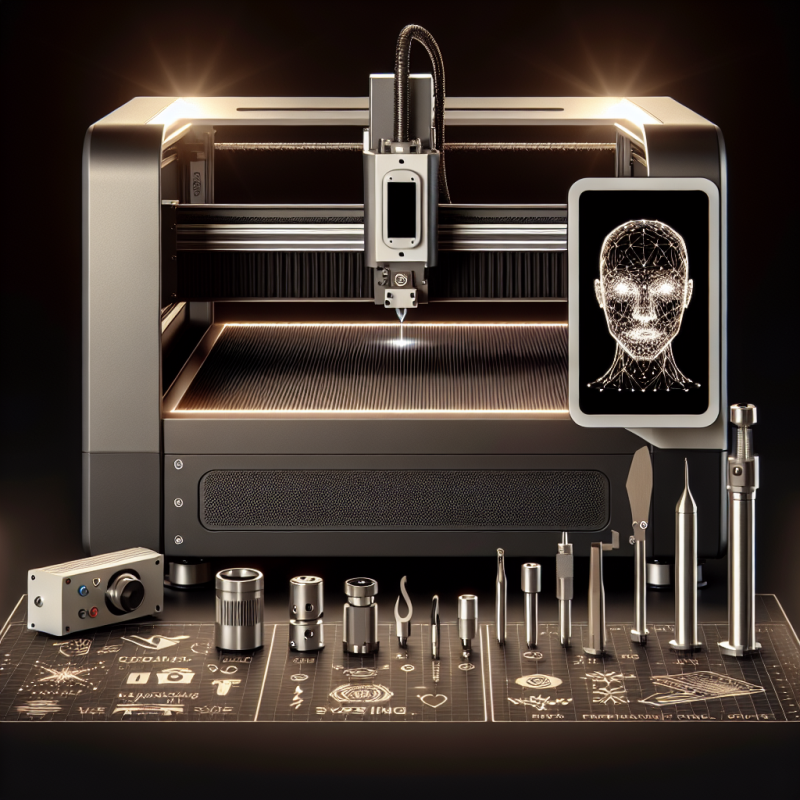

Machine Specifications and Features

When choosing a laser cutter balsa machine, it is essential to consider the specifications and features that best suit your needs. Here are some key aspects to look for:

- Laser Power: Higher power lasers can cut thicker materials faster and with greater precision. For balsa wood, a mid-range power level is usually sufficient.

- Workspace Dimensions: Ensure the machine’s workspace is large enough to accommodate your largest projects. Many models offer expandable workspaces for added versatility.

- Software Compatibility: Look for machines that are compatible with industry-standard design software such as Adobe Illustrator, AutoCAD, and CorelDRAW. This allows for seamless file transfer and project setup.

- Engraving Speed and Resolution: Faster engraving speeds and higher resolutions translate to shorter production times and finer details.

- Safety Features: Important safety features include emergency stop buttons, enclosed work areas, and exhaust systems to vent harmful laser fumes.

Material Compatibility

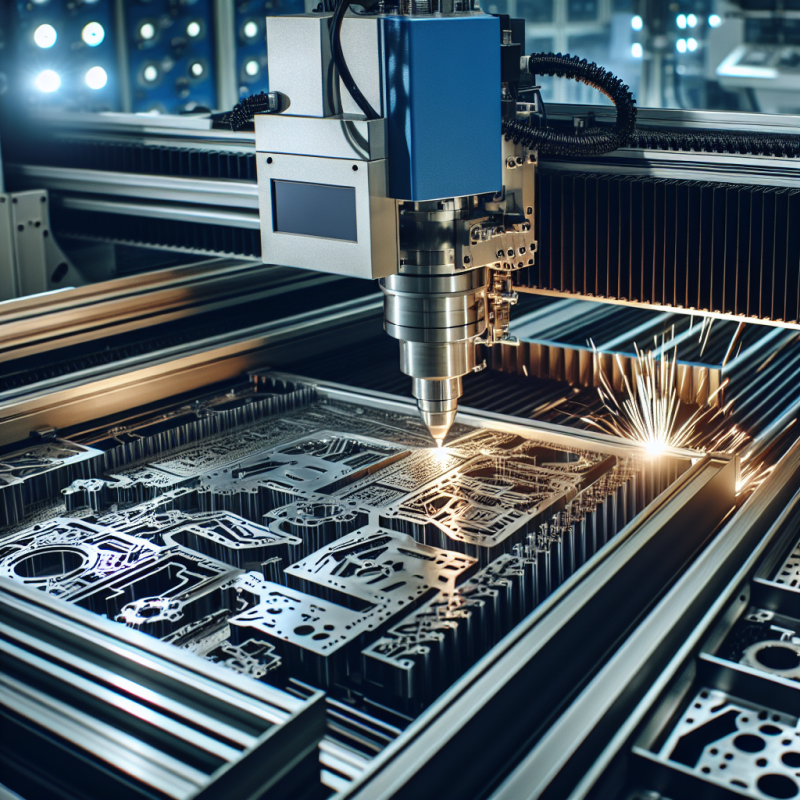

While laser cutter balsa machines excel at processing this specific material, they are also capable of working with a wide range of other substrates. Here are some materials commonly used with laser cutters:

- Woods: In addition to balsa, machines can cut and engrave a variety of woods, including plywood, MDF, and hardwood.

- Plastics: Acrylic, polyester, and polycarbonate are popular plastics for laser cutting due to their transparency and durability.

- Metals: Thin sheets of metals such as aluminum, stainless steel, and brass can be cut and marked with laser machines equipped with the right settings.

- Paper and Cardboard: Ideal for creating intricate papercuts and packaging prototypes.

- Leather and Fabrics: Lasers can be used to cut and engrave leather goods and fabrics with precision.

Safety Considerations

Operating a laser cutter balsa machine involves several safety considerations to ensure the well-being of operators and those in the vicinity. Here are some essential safety tips:

- Eye Protection: Always wear laser-safe glasses when operating the machine, even when viewing the process from a distance.

- Ventilation: Ensure proper ventilation to prevent the accumulation of laser-generated fumes and particles.

- Emergency Stops: Familiarize yourself with the machine’s emergency stop procedures and keep clear pathways to the stop buttons.

- Fire Precautions: Have a fire extinguisher handy and be prepared to respond quickly in case of a fire.

- Training: All operators should receive thorough training on machine operation, safety protocols, and emergency procedures.

Industry Best Practices

To get the most out of your laser cutter balsa machine and ensure consistent, high-quality results, follow these industry best practices:

- Calibrate Regularly: Regular calibration ensures that your machine maintains its precision over time.

- Use High-Quality Materials: Investing in high-quality materials will yield better results and extend the lifespan of your machine.

- Optimize Settings: Experiment with different laser settings to find the optimal parameters for each material and project.

- Clean and Maintain: Regular cleaning and maintenance, such as clearing debris from the work area and checking laser alignment, will keep your machine running smoothly.

- Backup Files: Regularly back up your design files to prevent data loss and ensure you can always access your work.

Cost-Benefit Analysis

Investing in a laser cutter balsa machine can be a significant expenditure, but the benefits often outweigh the costs. Here are some factors to consider:

- Initial Cost: While the upfront cost can be high, consider the long-term savings from reduced labor costs, increased productivity, and the ability to take on more complex projects.

- Versatility: The versatility of laser cutters, capable of working with multiple materials and producing a wide range of products, makes them a valuable addition to any creative or manufacturing workspace.

- Scalability: As your business grows, laser cutters can scale with you, offering increased capacity and the ability to take on larger projects.

Maintenance Tips

Proper maintenance is crucial for keeping your laser cutter balsa machine in top condition. Here are