Title: Laser Cutter for Metal: Precision Engraving and Cutting

Introduction

The rise of laser cutter for metal technology has significantly transformed industries across the board. These powerful machines bring precision, speed, and a level of detail unattainable with traditional engraving methods. This article delves into the different aspects of laser engraving, highlighting its technology, applications, specifications, and practical usage tips to help users maximize the potential of their engraving projects.

Laser Engraving Technology and Applications

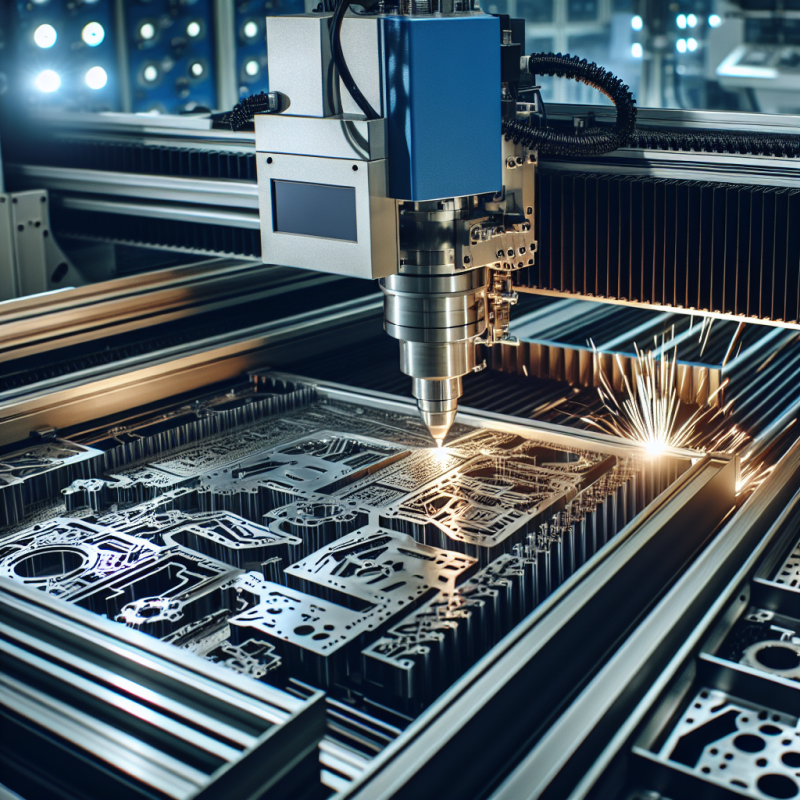

Laser engraving utilizes a highly concentrated beam of light to cut or engrave designs onto various surfaces. This process provides unparalleled accuracy and can be applied to a range of materials, including metals, plastics, and wood. The main advantage of a laser cutter for metal is its ability to create intricate designs at high speeds.

Applications of laser engraving machines are vast, spanning industries such as aerospace, automotive, jewelry, and signage. What truly sets the laser cutter apart is its capability to handle complex patterns and detailed images. But how does it achieve this, and what makes it so efficient?

Machine Specifications and Features

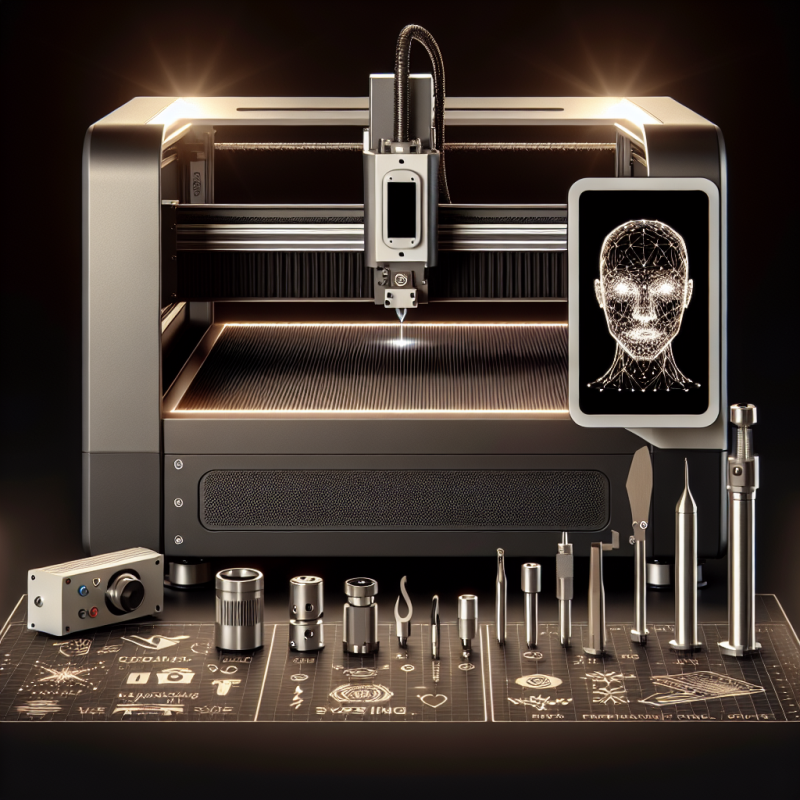

Key specifications to consider when choosing a laser cutter for metal include laser power, speed, and the machine’s software compatibility. Higher power lasers allow for deeper cuts into tougher materials, while software compatibility ensures ease of use and versatility in design creation. Features like portability, ease of setup, and user interface also enhance the usability of these machines.

The LaserPecker LP2, for example, is a portable and handheld laser engraver that includes photography-grade precision and speed. Its compact design doesn’t compromise on power or functionality, making it an excellent choice for both hobbyists and professionals.

Material Compatibility

Not all laser engravers are created equal when it comes to the materials they can process. A good laser cutter for metal will efficiently handle metals like stainless steel, aluminum, and brass. Some machines may offer options for engraving softer materials, like wood or acrylic, without requiring much adjustment.

Understanding material compatibility not only enhances the quality of the final product but also prolongs the life of the machine. Carefully choosing the right equipment based on the intended material use is critical for achieving desired results.

Safety Considerations

The use of lasers, especially in laser cutter for metal operations, demands a strong emphasis on safety. Operators should always wear protective eyewear to guard against possible laser exposure. Additionally, proper ventilation is crucial, as the engraving process can produce potentially harmful fumes and debris.

Most modern engravers come equipped with safety features like emergency stop buttons and protective covers. Nevertheless, adherence to the manufacturer’s guidelines and regular equipment checks can significantly reduce risks associated with laser cutting.

Industry Best Practices

To achieve the best results with a laser cutter for metal, operators should follow industry best practices. These include keeping the lens and mirrors clean, regularly checking for software updates, and ensuring all parts are in good working condition. Calibration of the machine should also be done periodically to maintain accuracy in engravings.

Cost-Benefit Analysis

Investing in a laser cutter for metal can be significant, yet the cost-benefit ratio leans positively when considering its precision, efficiency, and low material wastage. For businesses, the machinery can increase production speed and reduce labor costs. Furthermore, the ability to create custom designs enhances product value and marketability.

For hobbyists, the investment might be higher, but the endless potential for creativity and the satisfaction of creating intricate designs can offset the initial cost.

Maintenance Tips

Maintaining a laser cutter for metal is essential for ensuring its longevity and performance. Regularly cleaning the workbed and lenses can prevent buildup that may impair the machine’s functionality. Replace worn belts, tracks, and other components as needed to avoid operational hiccups.

Periodic professional maintenance checks will also ensure that all mechanical and electronic aspects are in top shape. Proper storage when not in use aids in protecting the equipment from dust and moisture.

Project Ideas and Tutorials

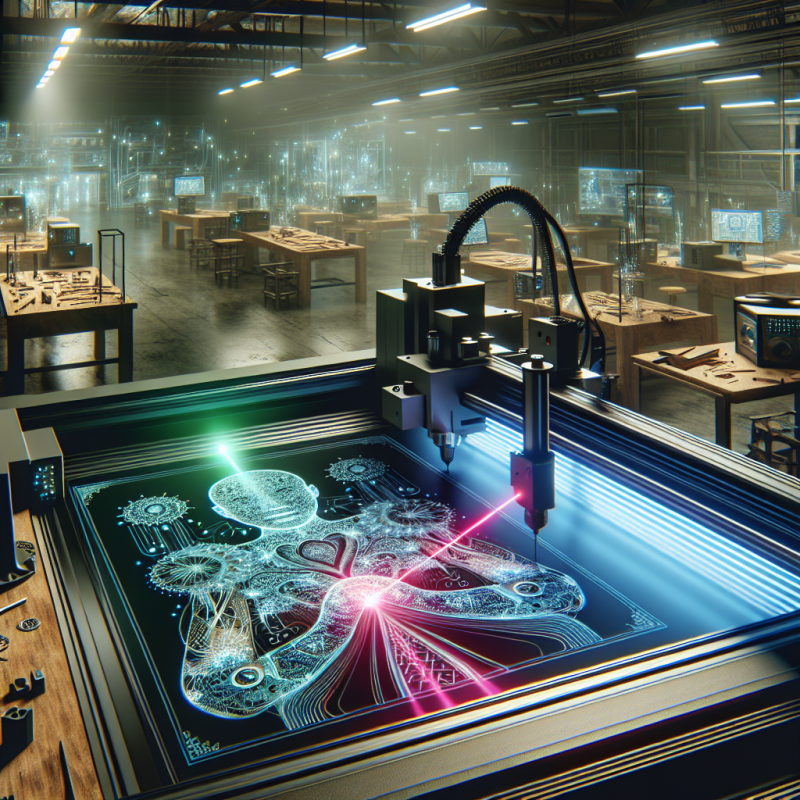

Experimenting with a laser cutter for metal opens the door to countless creative projects. Beginners might start with personalized keychains, engraved jewelry, or customized metal tags. More advanced users can explore intricate art pieces, signage, and architectural models.

Online communities and tutorials abound, offering inspirations and detailed guides on techniques and projects. Engaging with these resources not only sparks creativity but also enhances skills and understanding of laser engraving technology.

Real-World Case Studies

In various professional environments, the application of a laser cutter for metal has shown remarkable results. For instance, in the automotive industry, these machines produce custom parts with enhanced accuracy and reduced production time. Similarly, in jewelry design, laser engravers can etch detailed patterns onto metals, vastly improving both aesthetics and personalization.

Another notable case is in the signage industry. Companies are utilizing laser cutting technology to create bespoke signs that meet specific client requests. This level of customization has become a standard expectation, further solidifying the role of laser cutters in modern production workflows.

Leveraging Advanced Techniques

Beyond basic functionality, advanced techniques are transforming the ways operators can use a laser cutter for metal. Techniques such as vector engraving and raster engraving allow for different styles of engraving that can elevate a project’s quality. Understanding these methods can allow users to push the boundaries of their designs further.

Conclusion

The laser cutter for metal is a versatile and powerful tool that serves as a cornerstone in both industrial applications and personal creative endeavors. Its ability to deliver precision, efficiency, and versatility makes it a worthwhile investment. Whether you’re a professional seeking to enhance production capabilities or a hobbyist exploring new creative avenues, understanding every aspect of your machine will unlock its full potential.

With ongoing advances in laser technology, these tools are becoming more accessible, offering even more possibilities for customization and innovation. Are you ready to embark on your laser engraving journey?