Laser Engraved Baseball: Personalized Sports Art

Introduction

As consumer demand for personalized products grows, laser engraved baseball items are becoming increasingly popular. These unique creations captivate not only for their beauty but also for showcasing the advancements in laser engraving technology. Whether you’re an experienced user or a newcomer, this article explores the intricacies of laser engraving technology, its diverse applications, and much more.

Laser Engraving Technology and Applications

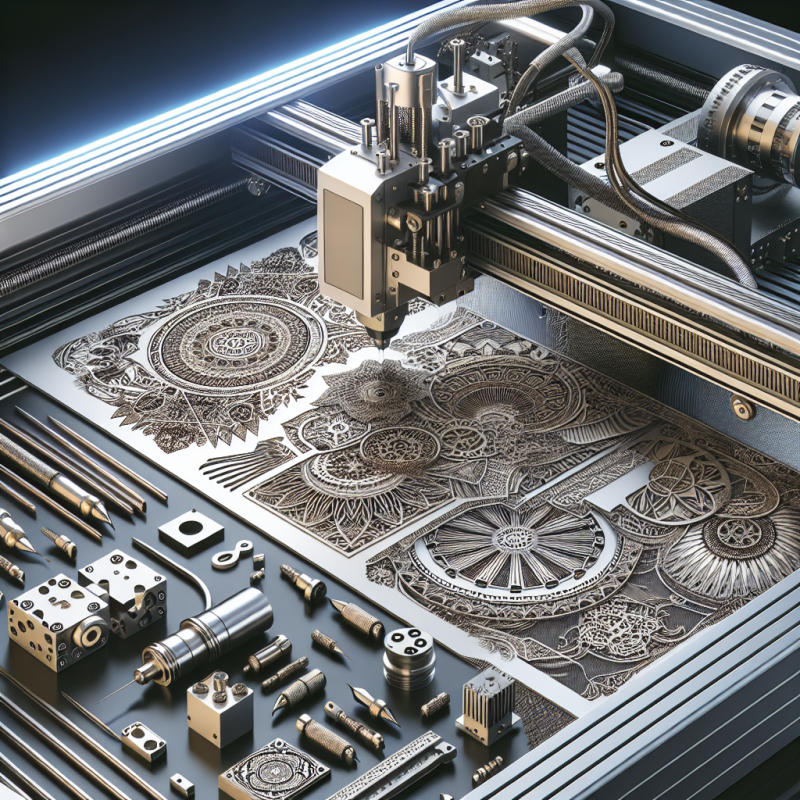

Gaining an understanding of laser engraving technology enhances appreciation for the fine artistry and precision these machines offer. Laser engraving leverages high-powered lasers to vaporize materials, resulting in intricate and detailed patterns. The technology finds applications in various fields, from crafting a laser engraved baseball for sports enthusiasts to creating personalized gifts.

What implications does this have for users? Does laser engraving have limitations? The machines’ versatility is evident in their ability to work with various materials, such as leather and wood, and metal and plastic. This flexibility broadens creative potential considerably.

Machine Specifications and Features

The specifications of a laser engraving machine crucially influence its performance and suitability for different tasks. Machines like the LaserPecker LX1 series boast features such as foldability, portability, and multi-functionality that cater to a wide range of user needs. How do these features impact workflow efficiency, and are they worth the investment?

It’s vital to consider aspects such as power output, engraving speed, and resolution when choosing a machine. Higher power output allows for deeper and faster engraving, while speed and resolution ensure detailed and high-quality engravings, particularly for intricate designs like a laser engraved baseball.

Material Compatibility

The wonders of laser engraving extend across a remarkable variety of materials, each producing unique effects. Which materials are optimal for crafting a laser engraved baseball?

Understanding the properties and limitations of different materials allows for more informed choices and superior outcomes. Common materials include:

- Wood: Provides a warm, natural finish suitable for rustic designs.

- Leather: Offers a luxurious appearance, ideal for premium items.

- Glass: Great for crafting elegant and sophisticated engravings.

- Metal: Durable and lasting, perfect for items subject to wear and tear.

- Plastic: Affordable and versatile, useful for prototypes and everyday items.

Safety Considerations

Safety is crucial when operating laser engraving machines. Adequate precautions minimize risks and ensure a secure working environment. What are critical safety measures to follow when using a laser engraving machine?

Below are some essential safety tips:

- Wear protective eyewear to shield eyes from laser exposure.

- Ensure proper ventilation to prevent inhalation of harmful fumes produced during engraving.

- Regularly inspect equipment for damage or wear that may impact safety.

- Keep a fire extinguisher on hand, especially when working with flammable materials.

Industry Best Practices

Following industry best practices enhances engraving quality and prolongs equipment lifespan. What do seasoned professionals recommend?

Regular maintenance, using compatible materials, and adhering to manufacturer instructions are vital. Engaging in relevant forums and communities also offers valuable insights from other users, enriching your understanding and skill in creating an outstanding laser engraved baseball.

Cost-Benefit Analysis

Investing in a laser engraving machine is a significant decision. How do you assess what offers the best value? Conducting a cost-benefit analysis helps understand potential returns on investment.

Though initial purchase and setup costs are high, consider the vast applications and potential revenue streams the machine can unlock. From producing custom items to offering unique services, the opportunities are immense. Assess the long-term benefits alongside the initial costs to determine your investment’s true value.

Maintenance Tips

To maintain peak performance, regular maintenance of your laser engraving machine is essential. What practices should be implemented?

Consider these maintenance tips:

- Routinely clean lenses and mirrors to avoid dust buildup that could affect laser precision.

- Frequently check the laser beam alignment, as misalignments may degrade engraving quality.

- Ensure software updates are installed to benefit from new features and improvements.

- Periodically lubricate moving parts to reduce wear and prolong machinery life.

Project Ideas and Tutorials

Owning a laser engraving machine invites creativity and experimentation. Engaging with project ideas and tutorials can maximize your equipment’s potential. What exciting projects can be pursued with a laser engraver?

Starting with tutorials for crafting a stunning laser engraved baseball is a great beginning. Other creative projects include:

- Personalized jewelry: Design custom pieces with intricate details.

- Customized home décor: Craft distinctive items that make a statement.

- DIY puzzles: Create and cut designs for bespoke puzzles.

- Gift boxes: Develop specially designed packaging that adds a unique touch.

Conclusion

A laser engraved baseball represents not just a personalized item, but the embodiment of modern technology, creativity, and precision. Engaging deeply with laser engraving machines opens a realm of endless creative possibilities. By mastering the technology, applications, specifications, and best practices, users can fully utilize their machine’s potential.

Embrace the learning journey, balance safety with creativity, and most importantly, let your imagination soar. The world of laser engraving awaits, offering limitless potential for creation limited only by your imagination.