Laser Engraving Acrylic Sheet: A Comprehensive Guide

Introduction

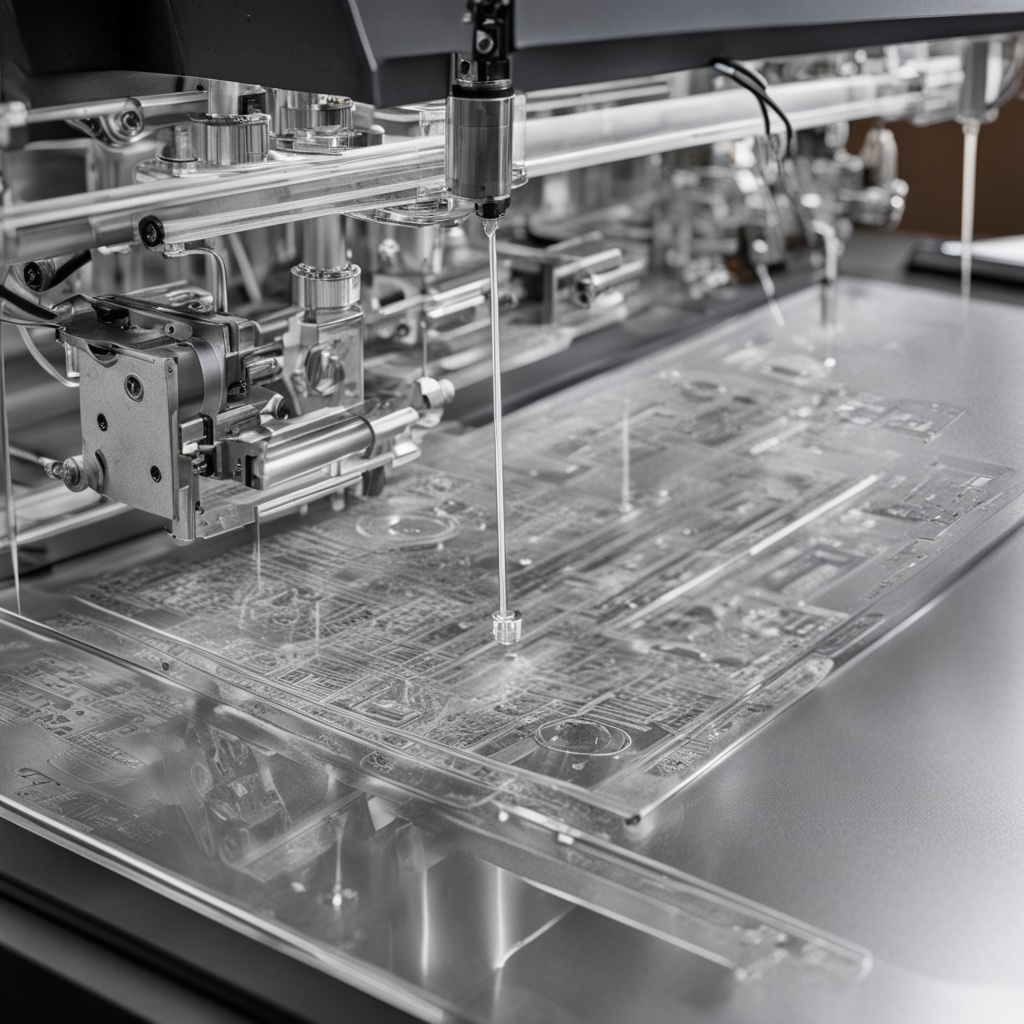

Laser engraving acrylic sheet has revolutionized the way we create intricate designs, logos, and text on transparent, translucent, and opaque acrylic materials. With the advent of advanced laser engraving machines, the possibilities for customization and personalization have expanded exponentially. This guide delves into the technology behind laser engraving acrylic sheet, machine specifications, material compatibility, safety considerations, industry best practices, cost-benefit analysis, maintenance tips, and exciting project ideas.

Laser Engraving Technology and Applications

Laser engraving technology employs high-intensity laser beams to vaporize the surface of a material, creating precise and detailed engravings. When it comes to laser engraving acrylic sheet, the process is particularly effective due to acrylic’s transparency and ability to transmit light in unique ways. This makes acrylic an ideal material for a variety of applications, including:

- Signage and Displays: Engraved acrylic signs offer high visibility and can be illuminated from within for a striking visual effect.

- Awards and Trophies: Personalized acrylic awards can feature intricate designs and text, making them stand out.

- Architectural Elements: Engraved acrylic panels can add a touch of elegance to interior design.

- Promotional Items: Customized acrylic keychains, phone cases, and other accessories make great promotional giveaways.

- Art and Crafts: Artists and craftspeople appreciate the versatility of acrylic for creating unique pieces.

Machine Specifications and Features

When selecting a laser engraving acrylic sheet machine, several specifications and features are crucial to consider:

- Laser Power: Higher laser power (typically ranging from 30W to 150W) allows for faster engraving speeds and deeper cuts.

- Beam Quality: A focused, high-quality laser beam ensures precision and detail.

- Workspace Size: The machine’s workspace should accommodate the largest pieces you plan to engrave.

- Software Compatibility: Look for machines that are compatible with industry-standard software like Adobe Illustrator, CorelDRAW, and AutoCAD.

- Material Handling: Features such as an automatic feed system and vacuum table can improve efficiency and accuracy.

- Safety Features: Essential safety features include emergency stop buttons, interlocks, and exhaust systems to vent harmful fumes.

Material Compatibility

Acrylic sheets come in various thicknesses, colors, and finishes, each affecting the engraving process differently. Clear acrylic transmits light well, making it suitable for backlighting applications. Colored acrylic absorbs light differently, which can create vibrant engraved lines. Textured acrylics can add an extra layer of visual interest to engraved designs. When working with laser engraving acrylic sheet, it’s important to adjust laser settings based on the material’s properties to avoid cracking, melting, or discoloration.

Safety Considerations

Laser engraving machines emit high-intensity laser beams and generate fumes that can be harmful if inhaled. Here are some essential safety tips:

- Personal Protective Equipment (PPE): Always wear laser safety goggles, gloves, and appropriate clothing to protect your eyes, hands, and skin.

- Ventilation: Ensure proper ventilation by using an exhaust system to vent fumes outside the workspace.

- Training: All operators should receive thorough training on machine operation and safety protocols.

- Emergency Procedures: Have an emergency stop plan in place and ensure all operators know how to respond in case of an accident.

- Regular Maintenance: Keep the machine clean and in good working condition to prevent accidents.

Industry Best Practices

To get the best results when laser engraving acrylic sheet, follow these industry best practices:

- Test Runs: Conduct test runs on scrap material to dial in the perfect laser settings for your project.

- Vector Files: Use vector graphics files (SVG, AI, EPS) for clean, scalable engravings.

- Focal Distance: Adjust the focal distance to ensure the laser beam is correctly focused on the material surface.

- Engraving Speed and Power: Balance engraving speed and laser power to achieve the desired depth and quality.

- Clean Material: Ensure the acrylic sheet is clean and free of dust, dirt, and scratches before engraving.

Cost-Benefit Analysis

Investing in a laser engraving acrylic sheet machine can be a significant expense, but the benefits often outweigh the costs. Here’s a breakdown:

- Initial Investment: High-quality laser engraving machines can range from several thousand to tens of thousands of dollars.

- Operating Costs: Ongoing costs include electricity, consumables like lenses and mirrors, and maintenance.

- Productivity: Laser engraving is faster and more efficient than manual methods, allowing for increased productivity.

- Customization: The ability to offer customized products can attract more customers and increase sales.

- Versatility: A single machine can handle a variety of materials and applications, maximizing return on investment.

Maintenance Tips

Proper maintenance is key to keeping your laser engraving acrylic sheet machine running smoothly and extending its lifespan:

- Regular Cleaning: Clean the lens, mirrors, and bed regularly to remove dust and debris.

- Lubrication: Apply lubrication to moving parts as recommended by the manufacturer.

- Alignment Checks: Periodically check and adjust the laser beam alignment to ensure precision.

- Software Updates: Keep the machine’s software up to date to benefit from the latest features and improvements.

- Preventative Maintenance: Schedule routine maintenance checks with a qualified technician.

Project Ideas and Tutorials

Ready to get started with your laser engraving acrylic sheet machine? Here are some inspiring project ideas and tutorials:

- Engraved Acrylic Coasters: Create personalized coasters with intricate designs and text.

- Backlit Signs: Design and produce signs with internal lighting for a stunning visual effect.

- Custom Keychains: Engrave unique patterns and text on acrylic keychains for a personal touch.

- Ornamental Panels: