Laser Engraving Machines: A Comprehensive Guide

Introduction

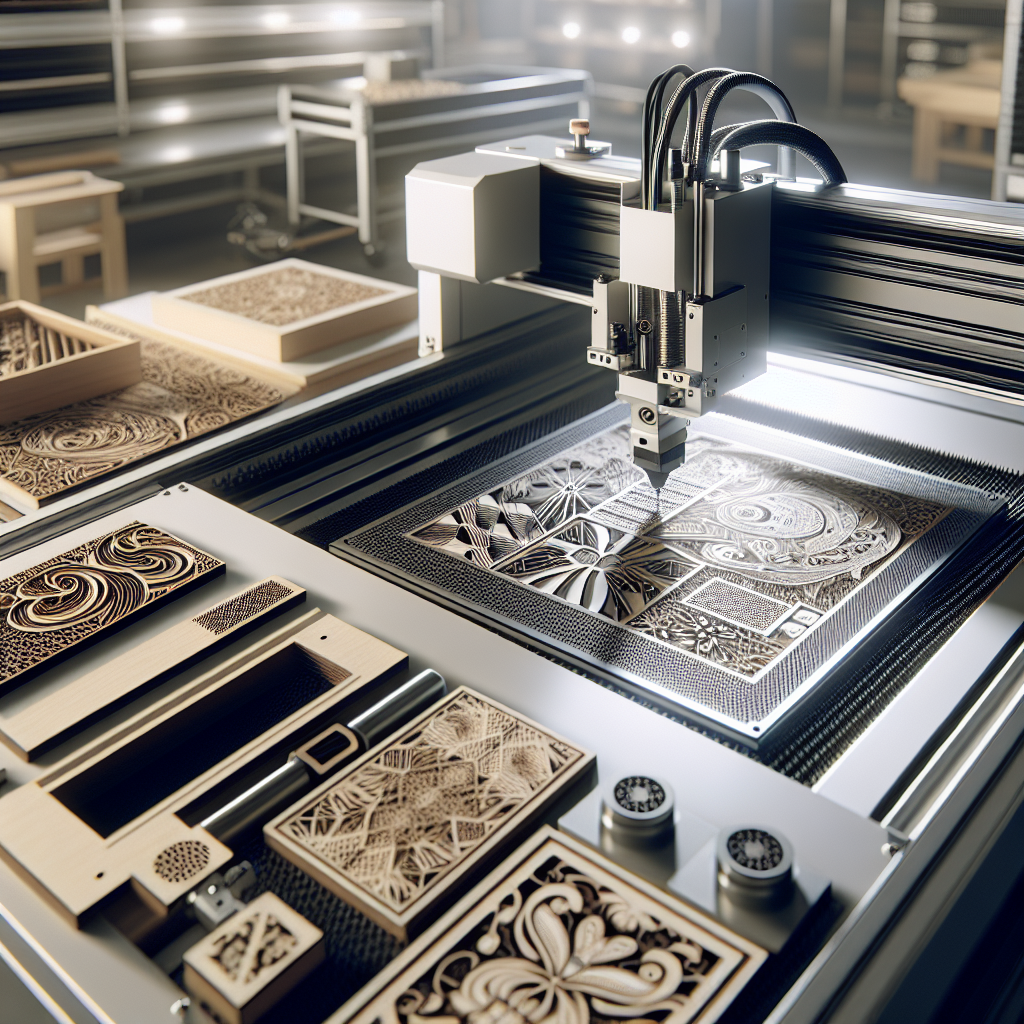

In recent years, the demand for laser engraving machines has increased significantly. Their versatility, precision, and broad range of applications make them indispensable tools for both hobbyists and professionals in various industries, serving creative and functional purposes.

Laser Engraving Technology and Applications

The core technology behind laser engraving machines involves the use of laser beams to remove surface material from objects, creating patterns or markings. This non-contact process is preferred for its precision and flexibility. These machines have broad applications across industries, including:

- Manufacturing: Part labeling and serializing.

- Jewelry Making: Intricate designs on metals.

- Crafting: Personalized gifts and decorations.

- Medical: Ensures traceability through engraving on medical instruments.

Have you ever wondered how these machines create such precise designs? The underlying technology is indeed complex and fascinating.

Machine Specifications and Features

When selecting a laser engraving machine, consider the following specifications and features:

- Laser Power: Influences the depth and speed of engraving.

- Engraving Area: Maximum size of the material that can be processed.

- Resolution: Affects detail and clarity of engravings.

- Software Compatibility: Flexibility in supporting various file formats is crucial.

Does the machine offer adjustable settings for different materials and projects? Consider this before making a purchase.

Material Compatibility

An advantage of laser engraving machines is their compatibility with numerous materials:

- Wood: Both softwoods and hardwoods can be engraved with varying depths.

- Metals: Suitable for aluminum, gold, and silver.

- Acrylic and Plastics: Ideal for cutting and engraving signs.

- Leather: Perfect for crafting personalized products.

Are there specific materials that should be avoided? Always refer to manufacturer guidelines to ensure optimal results and prevent machine damage.

Safety Considerations

Operating laser engraving machines safely is crucial. Here are some important safety tips:

- Wear protective eyewear to shield from laser radiation.

- Ensure proper ventilation to avoid inhaling fumes.

- Keep a fire extinguisher nearby in case of flammable material ignition.

- Regularly check and maintain the machine to avoid hardware malfunction.

Safety is a priority; always adhere to manufacturer safety instructions.

Industry Best Practices

What practices can enhance the efficiency and lifespan of laser engraving machines? Consider these:

- Regularly clean lenses and mirrors to maintain laser power and accuracy.

- Calibrate the machine accurately to ensure precision.

- Organize the work area to avoid clutter.

- Test samples before full-scale projects to refine settings.

Implementing these best practices can significantly improve the functionality and output quality of your machine.

Cost-Benefit Analysis

Consider the cost versus benefits of a laser engraving machine, especially for small businesses or artisans:

- Cost: Initial expenses are high, but it’s a long-term investment.

- Versatility: Handles various projects and personalized productions, adding value.

- Efficiency: Speeds up production and reduces labor costs.

- Quality: Offers superior finish compared to manual methods.

Weigh these factors to make informed investment decisions and maximize the benefits of this technology.

Maintenance Tips

Routine maintenance of a laser engraving machine ensures its longevity and performance.

- Keep optics clean from dust or debris.

- Lubricate moving parts to prevent wear and tear.

- Check for software updates to enhance functionality or fix bugs.

- Perform regular check-ups to identify potential issues early.

How often should maintenance occur? It depends on usage intensity but should generally follow a routine schedule.

Project Ideas and Tutorials

Consider the exciting projects possible with a laser engraving machine:

- Create custom jewelry pieces with engraved initials or designs.

- Design intricate patterns on wooden furniture to personalize.

- Engrave company logos on promotional products for gifts.

- Develop educational tools and puzzles using acrylic and wood.

Would you like in-depth tutorials on these projects? Numerous online resources and communities offer step-by-step guidance.

In conclusion, laser engraving machines present a world of possibilities. Understanding their technology, applications, and best practices allows you to leverage their advantages for superior projects and streamlined operations.