Laser Engraving Machines for Guns: A Comprehensive Guide

Introduction

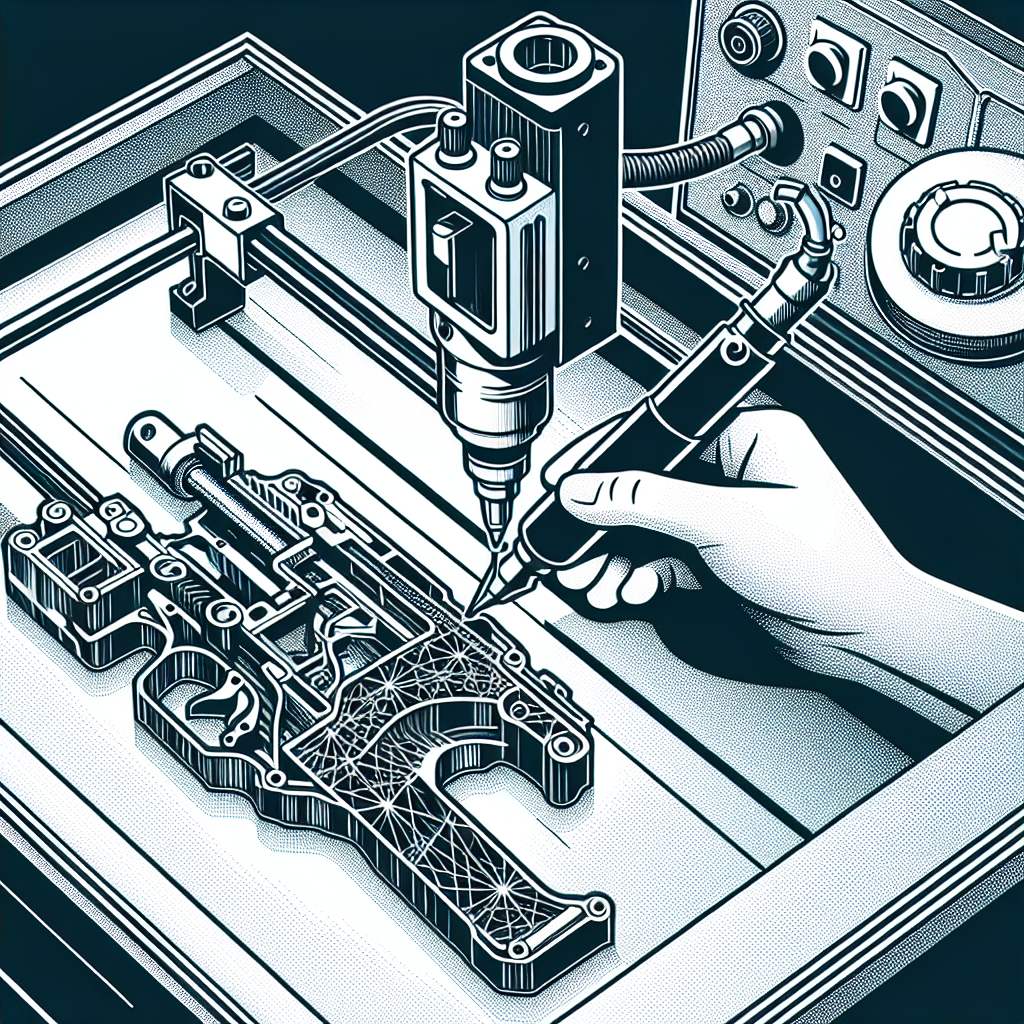

The precision and efficiency of laser engraving machine for guns have revolutionized firearms customization and identification. Imagine the ability to transform a standard firearm into a personalized piece of art or to mark it for distinct identification. This article delves into various aspects of laser engraving technology, focusing specifically on its application within the firearms industry.

Understanding Laser Engraving Technology

What makes laser engraving so popular, particularly in the world of firearms? At its core, laser engraving technology involves a focused laser beam that etches patterns or text onto a surface. The precision of this method allows for detailed designs and ensures that engravings are permanent and resistant to wear.

Applications of laser engraving extend beyond mere aesthetics. It’s also critical for compliance with laws requiring serial numbers and identifiable markings, contributing to firearm security and traceability. The laser engraving machine for guns is a versatile tool that provides solutions for both personal and professional use.

Key Specifications and Features

What should one look for in a laser engraving machine for guns? Understanding the specifications and features is essential.

- Power and Precision: The power of a laser directly affects engraving depth and speed. Higher wattage machines offer faster processing times.

- Software Compatibility: Modern machines come with intuitive software that ensures easy design uploads and adjustments.

- Versatility: Many machines can switch between different laser wavelengths, making them suitable for diverse materials.

- User Interface: A user-friendly interface will drastically reduce the learning curve, allowing for immediate operation.

- Cooling Systems: Advanced cooling mechanisms are crucial to maintain performance and extend the machine’s lifespan.

Material Compatibility

A crucial factor for any laser engraving machine for guns is its material compatibility. Firearms are made from a variety of materials including steel, aluminum, and polymer composites. Ensuring that the engraving machine can handle these materials is vital for optimal results.

Metal is often preferred for engravings due to its durability, and most machines are equipped to engrave metals effectively. For non-metal items like polymer frames, it’s important to adjust the laser settings to avoid material damage. Thus, choosing a machine with adjustable power settings can be a strategic investment.

Safety Considerations

Operating a laser engraving machine for guns safely is non-negotiable. Here are a few best practices for safe operations:

- Use Protective Gear: Always wear safety goggles to shield your eyes from the laser beam.

- Proper Ventilation: Ensure your workspace is well-ventilated to avoid inhaling any fumes generated during engraving.

- Machine Maintenance: Regular maintenance checks can prevent malfunctions and ensure all safety features are operational.

- Electrical Safety: Make sure all electrical components are securely grounded to prevent accidents.

Industry Best Practices

For businesses utilizing laser engraving machines for guns, adhering to industry best practices can enhance efficiency and product quality.

- Regular Training: Keeping staff updated with the latest laser engraving techniques and software is crucial.

- Quality Control: Implement a thorough checking system to ensure all engravings meet the desired standards.

- Customer Feedback: Engage with customers to refine and improve services based on practical feedback.

Cost-Benefit Analysis

Is investing in a laser engraving machine for guns worth it? Conducting a cost-benefit analysis can shed light on the financial implications and potential returns.

Initial investment costs can be significant, but the long-term benefits often outweigh the expenses. High precision reduces material waste, and customization capabilities can attract broader client bases, thereby increasing profit margins. Additionally, automation significantly cuts down labor costs and time.

Maintenance Tips

Proper maintenance of a laser engraving machine for guns extends its lifespan and maintains its efficiency. Here are some key tips:

- Regular Cleaning: Dust and debris can impact performance. Ensure the machine is regularly cleaned, especially the lenses and mirrors.

- Software Updates: Keep the operating software updated to prevent glitches and enhance performance.

- Component Checks: Inspect moving parts, belts, and alignment tools to prevent unexpected breakdowns.

Project Ideas and Tutorials

Curious about what projects can be undertaken with a laser engraving machine for guns? Here are some exciting ideas:

- Custom Hand Grips: Personalize firearm grips with intricate patterns or text for a unique look.

- Magazine Marking: Engrave magazines with logos or identification numbers for organizational purposes.

- Decorative Barrels: Add artistic designs to barrels for showpieces or personalized gifts.

- Sight and Accessory Markings: Clearly mark sights and other accessories to ensure quick identification.

In summary, a laser engraving machine for guns is an invaluable asset for anyone looking to enter the world of firearm customization and identification. From understanding the technology to implementing best practices, the journey to mastering this craft is both exciting and rewarding.

Do you have any questions about laser engraving machines? Whether it’s about specifications, safety, or maintenance, getting informed will ensure your engraving endeavors are successful and satisfying.