Laser Engraving Machines for Tumblers: Precision and Innovation

Introduction

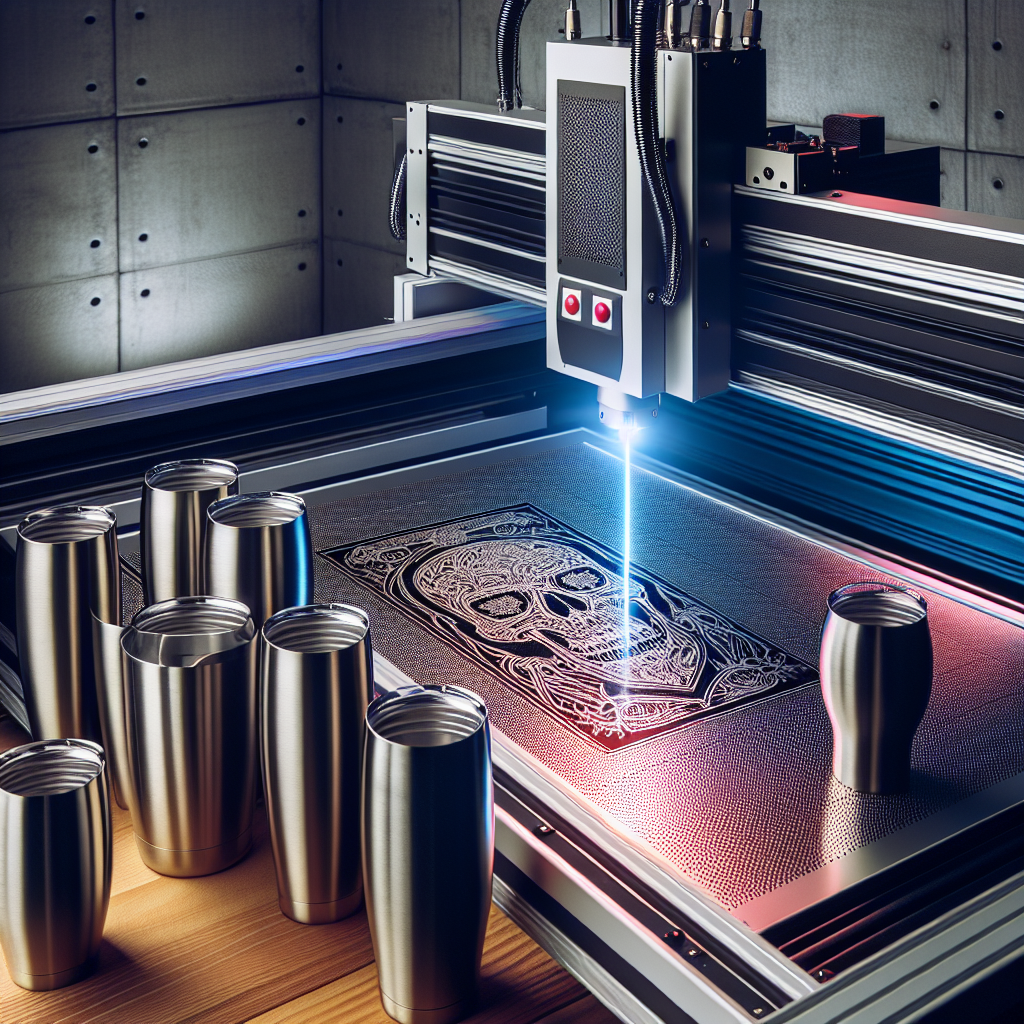

In the ever-evolving world of custom design and personalization, the laser engraving machine for tumblers has become a pivotal tool for creatives and businesses alike. These machines bring precision and style to an array of projects, transforming mundane items into works of art. Today, we explore why laser engravers are indispensable, diving into their technology, features, and the myriad ways they can be used to enhance and customize tumblers.

Understanding Laser Engraving Technology

At the heart of a laser engraving machine for tumblers is its sophisticated technology. The process utilizes a focused laser beam to etch designs onto surfaces. This technique allows for intricate patterns and fine details to be engraved with remarkable accuracy. Such precision is achieved through advanced software that translates complex designs into precise instructions for the laser.

This technology not only provides high-quality results but also operates with incredible speed, making it ideal for both one-off custom projects and large-scale production runs. The versatility of laser engravers means they can handle a wide range of materials, ensuring that no two projects are ever the same.

Key Features and Specifications

When selecting a laser engraving machine for tumblers, understanding its specifications and features is crucial. Let’s look at what makes these machines exceptional:

- Laser Power: The power of the laser dictates the types of materials you can engrave. Higher power systems can engrave tougher materials such as metals, while lower power settings are great for softer surfaces like wood and acrylic.

- Bed Size: The size of the engraving area determines how large of a tumbler or multiple items can be engraved simultaneously. Larger bed sizes offer more flexibility and efficiency.

- Resolution and DPI: With high-resolution capabilities, these machines can produce highly detailed images similar to photo quality, which is essential for intricate designs.

- Cooling System: This feature ensures the machine does not overheat, allowing for longer operation times without compromising on safety.

Material Compatibility

The allure of a laser engraving machine for tumblers lies in its ability to engrave a diverse range of materials. From stainless steel and aluminum to glass and plastic, these machines can handle it all with ease.

Selecting the correct settings is essential for optimal results. For instance, metals require a high-power laser and might benefit from a pretreatment to enhance the contrast. Plastics, on the other hand, need a lower power and slower speed to prevent melting or warping.

Safety Considerations

With the power and precision of a laser engraver comes the need for careful safety measures. It is vital to operate the machine in a well-ventilated area as fumes from certain materials can be hazardous. Ensuring proper eye protection is worn is equally important, as the intensity of the laser can be damaging if viewed directly.

Many machines come equipped with safety shutdown features that automatically power off the laser if it detects any anomalies, thus preventing potential accidents.

Industry Best Practices

Adhering to industry best practices ensures the longevity and efficiency of your laser engraving machine for tumblers. Regular maintenance, such as cleaning the laser lens and checking the alignment, can significantly impact the quality of your engravings.

Additionally, utilizing design software that is compatible with your machine can streamline the engraving process and enhance the quality of the output.

Cost-Benefit Analysis

Investing in a laser engraving machine for tumblers can initially seem costly but proves beneficial over time. These machines offer unparalleled versatility, opening up a plethora of creative possibilities. For small businesses, the ability to offer customized products can yield a significant return on investment.

The durability and efficiency of these machines mean reduced downtime and consistent production quality, further enhancing their value proposition.

Maintenance Tips

To get the most out of your engraving machine, regular maintenance is essential. Keep the machine clean and free of debris; dust and particles can impact performance and quality. Regularly inspect and replace consumables such as the laser tube or optics to keep the machine in optimal condition.

Conducting routine checks on software updates ensures that your machine runs efficiently and remains compatible with the newest design programs.

Project Ideas and Tutorials

The creative potential with a laser engraving machine for tumblers is virtually limitless. Here are some project ideas to spark your creativity:

- Create personalized tumblers for events or corporate gifts, featuring logos and names.

- Design intricate artwork that transforms tumblers into keepsakes.

- Experiment with color fills post-engraving for a multicolored effect.

- Develop tutorials on how to engrave complex designs for those new to the craft.

Whether for personal use or expanding a business, a laser engraving machine offers a world of opportunities. Embracing this technology can enhance creativity, personalization, and quality, making every project successful.

Conclusion

The impact of the laser engraving machine for tumblers on both the creative and business landscapes cannot be overstated. These machines combine precision and efficiency, catering to a wide range of materials and industries. By understanding their features, maintenance, and potential applications, users can unlock a world of innovative possibilities.

Are you ready to take your projects to the next level with a laser engraving machine? Consider how this technology could transform your approach to creativity and customization today.