Laser Engraving Machines: Harnessing the Power of Precision

Introduction

In the rapidly advancing world of engraving, laser for engraving machine technology has carved out a significant niche. Offering unrivaled precision and versatility, these machines have transformed how businesses and hobbyists access engraving capabilities. As an expert in laser engraving machines, this article will delve into various aspects, from the technology behind these machines to their practical applications and beyond.

Laser Engraving Technology and Applications

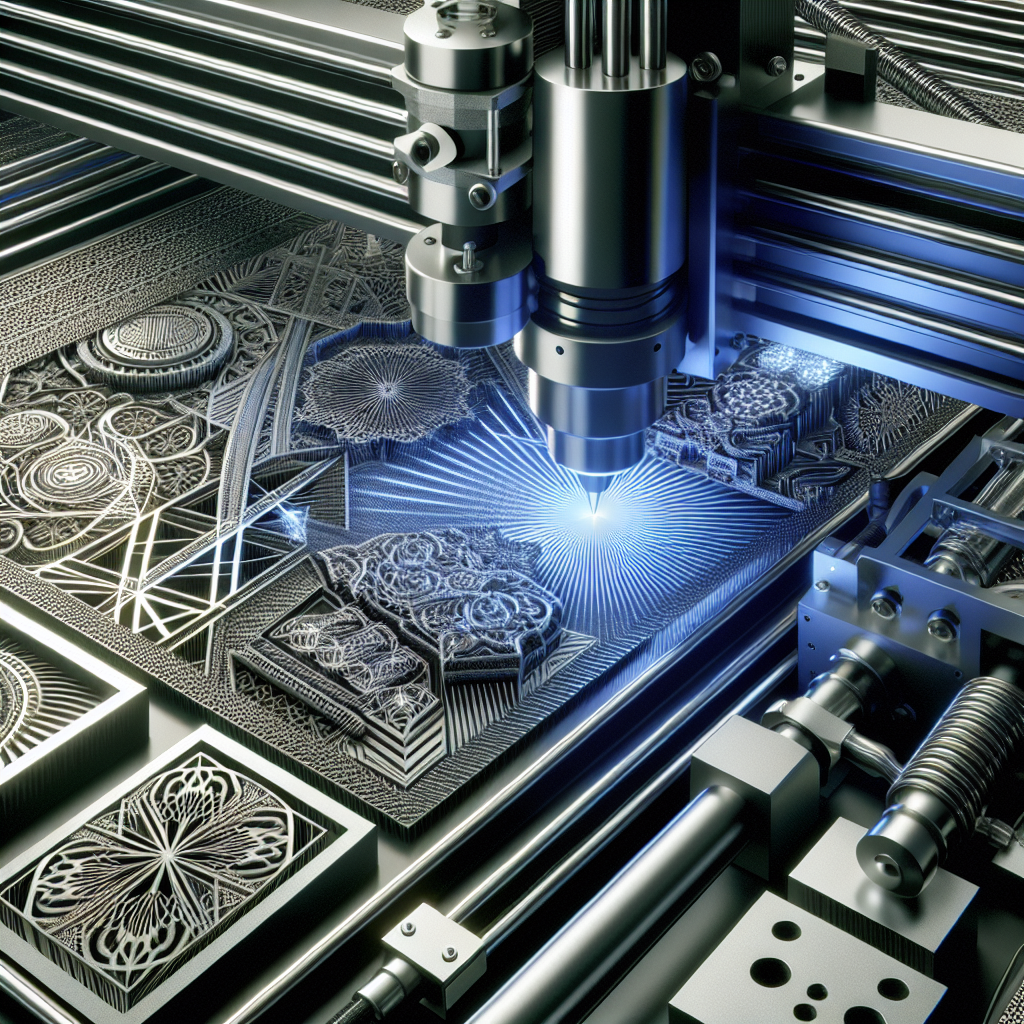

Laser engraving machines employ concentrated light beams to etch designs onto surfaces with astounding accuracy. This technology is utilized in a multitude of industries, from manufacturing to personalization. The ability to engrave intricate patterns on a diversity of materials like metal, plastic, and glass confirms the unequaled adaptability of lasers.

Applications range from creating intricate jewelry designs to etching serial numbers on industrial parts. Businesses leverage laser for engraving machine technology to provide customized products, adding value and creating unique customer experiences. Furthermore, laser engraving is popularly used in arts and crafts, enabling artists to bring their visions to life on various mediums.

Machine Specifications and Features

When discussing laser for engraving machine specifications, power, speed, and resolution are key factors. Machines like the LaserPecker LP3 offer high precision with robust capabilities, often coupled with user-friendly software interfaces for seamless operation. The power of the laser determines its capacity to cut or engrave different materials, while speed impacts the efficiency of production.

Key features may include:

- Adjustable laser power settings for different materials

- High-resolution capabilities for detailed designs

- Portable and compact designs for smaller workspaces

- Pre-installed safety mechanisms

Material Compatibility

One of the most crucial considerations for using a laser for engraving machine is its material compatibility. These machines are remarkably diverse in handling multiple materials. Metals like steel and aluminum, plastics, woods, glass, leather, and even certain composites can be engraved with suitable laser settings.

Understanding material properties is essential. For instance, certain plastics might release harmful fumes upon laser engraving, requiring appropriate ventilation. Metals reflect light more than other materials, necessitating precise adjustments to the laser intensity.

Safety Considerations

Safety is paramount when operating laser engraving machines. The concentrated light of lasers can pose risks, including skin burns or eye damage. Users must adhere to safety guidelines such as wearing protective eyewear and ensuring machines are operated in well-ventilated areas.

Additionally, modern laser for engraving machine models often include safety features like automatic shutdown when the machine is opened during operation, enhancing user safety.

Industry Best Practices

Best practices in laser engraving encompass proper handling, operation, and maintenance of the equipment. Regularly cleaning the machine and replacing parts as needed ensures lasting performance and accuracy. Operators should be well-trained and understand the specific settings for different materials to avoid wastage and ensure quality output.

Furthermore, businesses are advised to stay updated with industry trends and technological advancements to remain competitive in offering cutting-edge solutions.

Cost-Benefit Analysis

Investing in a laser for engraving machine can be a significant financial commitment. However, the cost is often justified by the machine’s versatility and the precision it brings to any engraving operation. From customizing promotional products to manufacturing precision components, these machines enhance production capabilities, offering a strong return on investment.

When assessing the costs, potential buyers should consider not just the machine price but also operational expenses such as maintenance, required materials, and potential software updates. Balancing these costs against the potential revenue increase and market opportunities the machine unlocks is crucial.

Maintenance Tips

Reliable operation of a laser for engraving machine depends on regular maintenance. Operators should schedule periodic cleaning to remove residue buildup on optical components and check for alignment issues, which can affect engraving quality.

Inspecting and, if necessary, replacing the ventilation filters ensures that fumes and dust do not compromise the machine’s internal components. Furthermore, software updates often include performance enhancements and should not be overlooked.

Project Ideas and Tutorials

The versatility of laser engraving machines opens the door to endless creative possibilities. From crafting personalized gifts like engraved wine glasses and wooden plaques to high-precision industrial projects such as part labeling and prototype creation, the scope of projects is vast.

Several online platforms and communities share tutorials and project ideas, providing inspiration and guidance for both beginners and seasoned professionals. Engraving enthusiasts can find step-by-step instructions for setting up projects, optimizing designs, and achieving professional-grade results.

Conclusion

The rise in popularity of laser for engraving machine technology underscores its importance across various fields. With the ability to transform simple objects into personalized masterpieces, the potential for creativity and customization is boundless. By understanding the technology, maintaining safety standards, and keeping abreast of industry practices, both businesses and individuals can fully harness the capabilities of laser engraving machines.