Laser Engraving Machines: Transforming Signage Creation

Introduction

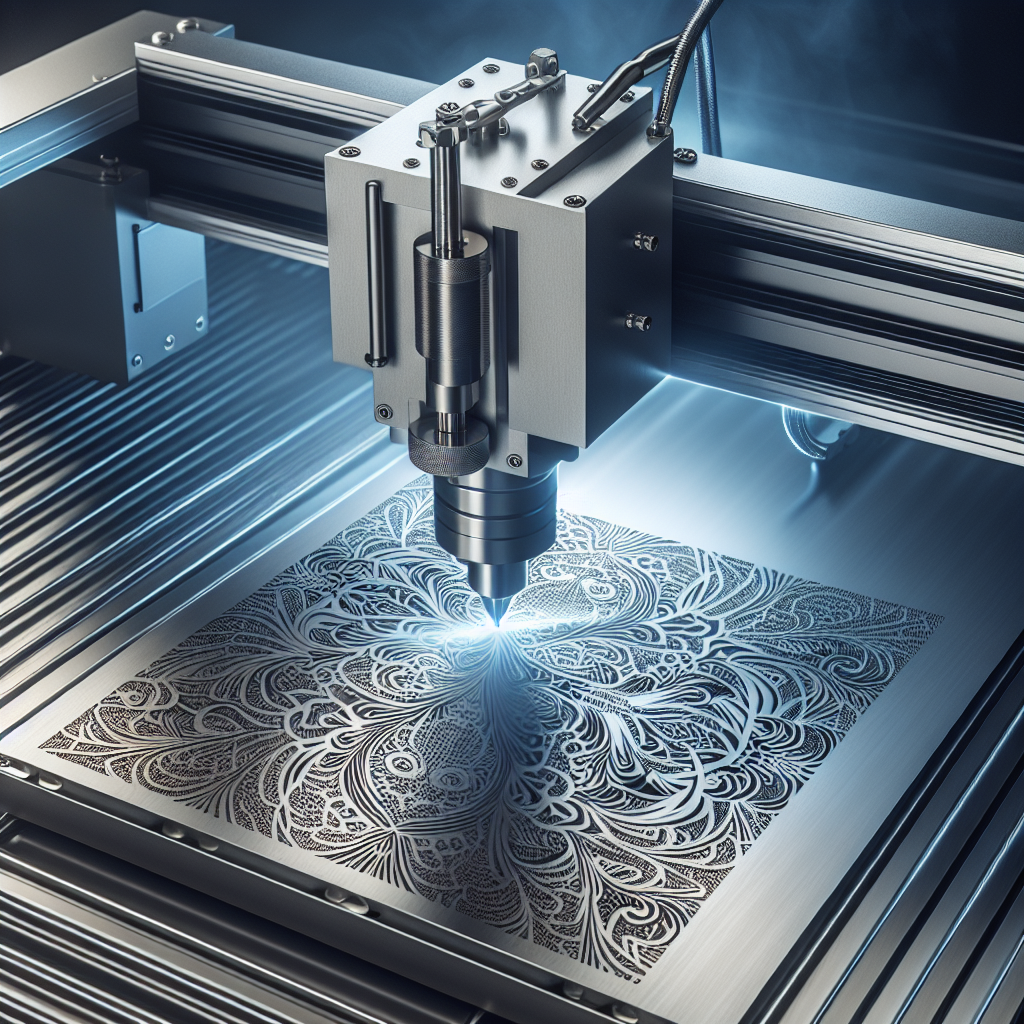

In the realm of modern technology, laser engraving has emerged as a critical tool, providing precision and versatility across numerous applications. Among these, the use of a metal cutting machine for signs stands out for its ability to transform how signage is designed and manufactured. From enhancing aesthetics to boosting efficiency, laser engravers have become indispensable in the signage industry.

Laser Engraving Technology and Applications

Laser engraving employs focused beams of light to etch patterns, text, or images onto various materials with remarkable precision. This technology enables intricate designs that are both durable and visually appealing, perfect for the signage industry. A metal cutting machine for signs can accurately cut and engrave on materials like aluminum, brass, and stainless steel, making it suitable for applications ranging from simple nameplates to intricate corporate logos.

Curious about incorporating laser engraving into your business? These machines extend beyond signage, useful in creating personalized gifts, industrial components, and jewelry, offering versatility unmatched by traditional methods. What are your primary interests for using laser engraving technology?

Machine Specifications and Features

The effectiveness of a metal cutting machine for signs heavily relies on its technical specifications. An exemplary model is the LaserPecker LP5, a smart 20W fiber diode laser engraver, designed for both beginners and seasoned users. This machine features an intuitive interface for easy operation while delivering powerful performance.

- Laser Power: 20W fiber laser for faster engraving and cutting speeds.

- Precision: High-resolution detail with precision up to 0.01mm.

- Material Compatibility: Handles various metals, perfect for creating high-quality signs and plaques.

- User-Friendly: Features smart app control for seamless operation.

- Customization: Adjustable settings cater to specific project needs, enhancing versatility.

Do you prioritize speed or detail in your projects?

Material Compatibility

When selecting a metal cutting machine for signs, material compatibility is crucial. Engraving metals requires a machine capable of handling toughness without sacrificing detail. The LaserPecker LP5 supports metals such as brass, steel, and aluminum, eliminating material constraints for creative designs in the signage industry.

Wondering about non-metal materials? Many laser engravers designed for metal can also work with wood, plastic, and leather, broadening project opportunities. What materials do you work with the most?

Safety Considerations

Operating a laser engraving machine involves essential safety precautions to prevent accidents. Protective eyewear is necessary to shield eyes from laser exposure, and proper ventilation must be ensured to avoid inhaling harmful fumes during engraving. Are safety protocols for laser engraving machines part of your current practice?

What safety protocols should you follow with a metal cutting machine for signs? Machines are typically equipped with safety features like emergency stop functions for rapid operation halts if needed. Consistent maintenance checks are crucial for safe, effective use.

Industry Best Practices

To maximize the efficiency and lifespan of your metal cutting machine for signs, adopting industry best practices is key. This involves regular maintenance, keeping the machine’s optics clean, and precise calibration, paired with using correct laser settings for each material.

- Regular cleaning prevents residue buildup on engraved materials.

- Periodically check and realign the laser beam.

- Utilize appropriate laser parameters for optimal cutting and engraving quality.

How often do you perform maintenance on your equipment?

Cost-Benefit Analysis

Investing in a metal cutting machine for signs may seem costly initially, but a cost-benefit analysis highlights substantial advantages. It streamlines production, reduces material waste, and lowers labor costs. Precise cutting and intricate engraving enhance the quality and appeal of finished products, ensuring a significant return on investment.

Have you considered the long-term savings laser engraving machines can offer? By minimizing production errors and facilitating bulk processing, these machines significantly reduce operational costs over time.

Maintenance Tips

Proper maintenance ensures that a metal cutting machine for signs stays operational and efficient over time. Regular inspection and cleaning prevent buildup and mechanical issues, preserving the machine’s accuracy and speed.

- Inspect and clean lenses and mirrors to remove dust and debris.

- Lubricate moving parts according to manufacturer guidelines.

- Perform diagnostics to verify system functionality.

Project Ideas and Tutorials

Owning a metal cutting machine for signs opens a world of creative possibilities. Projects can range from crafting custom nameplates and signage to developing intricate art pieces. Numerous online tutorials and guides assist newcomers in mastering laser engraving techniques.

Need inspiration? Begin with simple designs, gradually tackling more complex projects as you become familiar with your machine’s capabilities. Consider creating custom corporate logos or personalized door signs as starting projects. What type of project would you like to attempt next?

Conclusion

The adoption of laser engraving technology, especially with a metal cutting machine for signs, has profoundly transformed the signage industry. With benefits like high precision, versatility, cost efficiency, and ease of use, these machines are a valuable asset for businesses seeking to elevate their manufacturing capabilities. Embrace this innovation and explore the limitless creative possibilities that laser engraving offers. How will you integrate these advances into your business strategy?