Laser Engraving Marble: Precision and Elegance Combined

Introduction

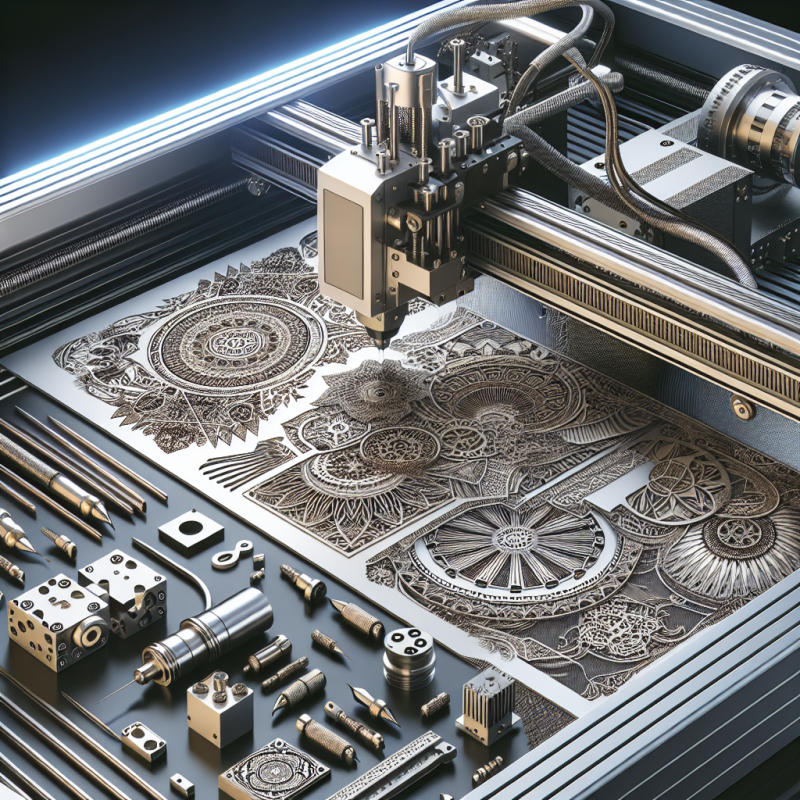

The art of laser engraving marble transcends traditional crafting methods, offering precision and creativity in transforming a simple piece of stone into a work of art. Harnessing modern technology, laser engraving machines have emerged as indispensable tools for artists, designers, and manufacturers alike. This article focuses on exploring the multifaceted applications, technology, and best practices involved in laser engraving marble, along with insights into machine specifications, material compatibility, and maintenance.

Understanding Laser Engraving Technology

Laser engraving technology operates on the principle of using a concentrated beam of light to etch designs onto various materials. In the case of laser engraving marble, the machine precisely ablates the surface to create intricate patterns, texts, or images. The flexibility and detail achievable with laser engraving are unparalleled, making it a favored choice in both artistic and industrial applications.

Applications of Laser Engraving on Marble

Marble has long been revered for its elegance and durability, and when combined with laser engraving, it becomes a medium for countless applications. Some popular uses include:

- Creating personalized home decor pieces

- Designing custom awards and trophies

- Etching memorial stones and plaques

- Crafting intricate architectural designs

Each application takes advantage of the precision and aesthetic appeal of laser engraving, transforming marble into a canvas for lasting impressions.

Specifications and Features of Laser Engraving Machines

With the demand for laser engraving marble rising, understanding machine specifications is crucial for achieving optimal results. Key features to consider include:

- Laser Power: Determines the depth and speed of engraving

- Resolution: Higher DPI allows for finer detail

- Work Area: Size of the material that can be processed at once

- Cooling System: Ensures the machine operates effectively without overheating

These features contribute to the machine’s capability to perform complex engravings with high levels of precision and efficiency.

Material Compatibility

Not all lasers are created equal when it comes to material compatibility, especially for laser engraving marble. It is essential to select a machine equipped to handle the density and structure of marble. CO2 laser engravers are typically the most suited for this task due to their wavelength and ability to efficiently work with harder materials.

Safety Considerations

Operating any laser engraving machine requires adherence to strict safety protocols to prevent accidents and ensure user welfare. Key safety practices include:

- Wearing protective eyewear to shield against laser exposure

- Ensuring proper ventilation to avoid inhalation of dust and fumes

- Following manufacturer guidelines rigorously

- Keeping the work area organized to prevent mishaps

By maintaining a safe environment, users can focus more on the creative aspects of laser engraving marble.

Industry Best Practices

Adopting industry best practices enhances the quality and efficiency of laser engraving marble. Here are some strategies to consider:

- Regularly calibrating the machine for accurate results

- Utilizing software tools for design precision

- Conducting test runs to fine-tune settings

- Staying updated with the latest technology trends

Implementing these practices ensures that engravings are not only precise but also executed in a time-efficient manner.

Cost-Benefit Analysis

For many, the decision to invest in a laser engraving machine is influenced by a cost-benefit analysis. Laser engraving marble offers numerous advantages such as high precision, reduced labor costs, and the ability to create bespoke designs that justify the initial investment. Over time, the savings on manual craftsmanship and the ability to scale production can result in substantial economic benefits.

Maintenance Tips

To maximize the lifespan and performance of a laser engraving machine, regular maintenance is essential. Here are some tips to keep your machine in top condition:

- Regularly clean the optics and mirrors

- Check and replace filters as needed

- Inspect belts and components for wear and tear

- Lubricate moving parts to prevent rust

Maintaining your machine ensures that it not only performs effectively but also sustains high-quality laser engraving marble for years to come.

Creative Project Ideas and Tutorials

For those looking to embark on new projects, laser engraving marble offers abundant opportunities for creativity. Some ideas include:

- Creating personalized coasters or tabletops with intricate designs

- Designing custom kitchen backsplashes

- Developing educational or decorative wall panels

- Engraving decorative sculptures or garden stones

Online tutorials and a supportive maker community can provide further inspiration and guidance on executing these projects.

Conclusion

The realm of laser engraving marble is rich with possibilities, demanding an understanding of technology, materials, and methods to fully exploit its potential. Whether you are a hobbyist seeking to express your creativity or a business aiming to optimize production, laser engraving offers a path to success. By leveraging the insights and advice outlined here, you can embark on your journey with confidence, transforming raw materials into stunning works of precision and art.