Laser Engraving Technology: A Complete Guide

Introduction

In the realm of modern manufacturing and crafting, laser engraving technology has become a cornerstone for precision and creativity. Specifically, when it comes to working with robust materials like stainless steel, the process known as laser engraving stainless plays a vital role. This article will delve into the intricacies of laser engraving machines, such as the LaserPecker LX1 Series, and their diverse applications in industries ranging from jewelry manufacturing to industrial design.

Understanding Laser Engraving Technology

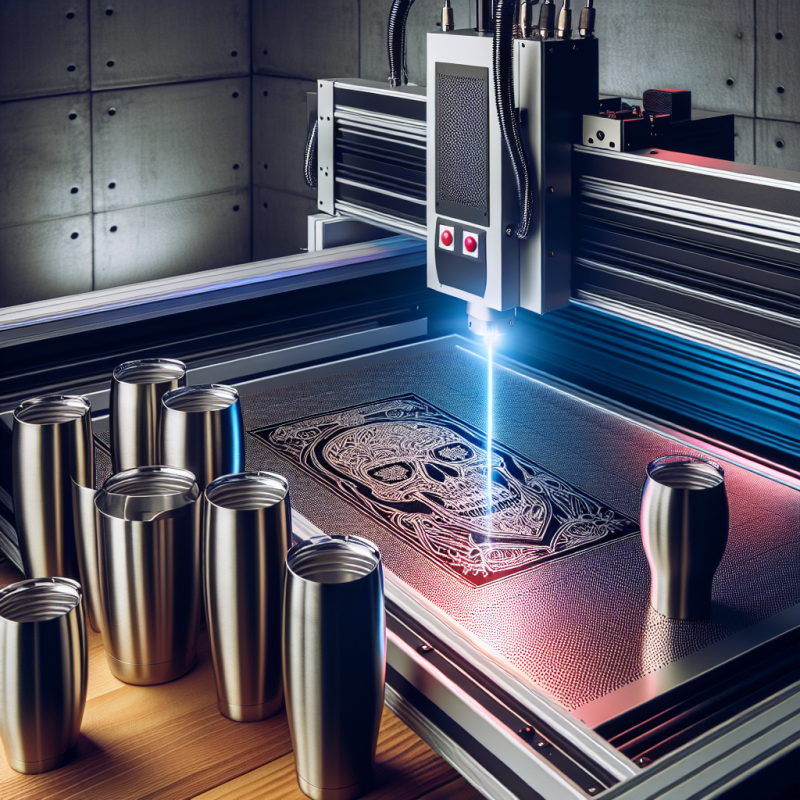

Laser engraving is a method of using concentrated laser beams to etch designs, text, or patterns onto various surfaces, including metals like stainless steel. This technology has revolutionized how intricate designs are implemented, allowing for high precision and repeatability. But how does it work on a technical level?

At its core, the process involves a high-powered laser beam directed onto the stainless steel surface. The heat from the laser vaporizes the material, leaving a precise incision that can be stark in contrast to the untreated areas. The result is a permanent, highly detailed mark suitable for a range of applications. This makes laser engraving stainless a sought-after technique in many industries.

Machine Specifications and Features

The capabilities of a laser engraver, such as the LaserPecker LX1 Series, depend heavily on its specifications and features. Key aspects include laser power, resolution, speed, and ease of use. The LaserPecker LX1 Series is characterized by:

- Foldable design, facilitating portability and ease of storage

- Multi-functional capabilities, allowing for both cutting and engraving tasks

- Adjustable laser power settings to suit different materials

- User-friendly interface for design import and modification

Choosing a machine with the right specifications is crucial for maximizing efficiency and ensuring the end product meets quality standards. When engaging in laser engraving stainless, features like these are indispensable.

Material Compatibility

Stainless steel is a popular choice for laser engraving due to its durability and resistance to corrosion. However, not all laser engraving machines are suited for it. It requires a machine capable of providing the specific power and speed settings necessary to engrave without damaging the integrity of the stainless steel. The LaserPecker LX1’s compatibility with various material types is a testament to its versatility.

Safety Considerations

Using a laser engraving machine safely is paramount. High-intensity lasers pose risks that necessitate careful safety protocols. Here are some critical safety measures:

- Wear protective eyewear to prevent laser-induced damage to the eyes

- Ensure proper ventilation as the engraving process can produce fumes and dust

- Regular maintenance checks to avoid unexpected malfunctions

Safety is as important as the quality and precision of your work. Therefore, adherence to these practices ensures the well-being of those handling the machines.

Industry Best Practices

When engaged in laser engraving stainless, adhering to industry best practices can significantly enhance the final product’s appearance and durability. Some of these practices include:

- Calibrating the laser before every session for consistency

- Using appropriate software for accurate design translation

- Testing on sample materials to adjust settings accordingly

By incorporating these best practices, users can achieve optimal results while minimizing waste and errors.

Cost-Benefit Analysis

The initial investment in high-quality laser engraving equipment may seem substantial. However, the costs can be offset by the benefits it brings. Consider the following:

- Increased production efficiency due to automation

- Higher product outputs owing to precision and repeatability

- Enhanced quality and durability of engraved items

Laser engraving stainless proves economically beneficial in the long run, particularly for businesses that require bulk operations or customizations.

Maintenance Tips

Regular maintenance is necessary to keep a laser engraving machine in optimal working condition. Here are some essential tips:

- Clean the laser optics regularly to ensure clear and precise beam delivery

- Check and replace the air filters to maintain proper ventilation

- Lubricate moving parts to prevent mechanical wear

These strategies not only prolong the life of the equipment but also sustain its high performance levels.

Project Ideas and Tutorials

If you’re a beginner or looking to expand your portfolio, here are some project ideas:

- Personalized keychains and jewelry with intricate designs

- Custom plaques and awards for corporate events

- Decorative metal art pieces for home or office decor

With the right machine like the LaserPecker LX1, the possibilities are endless. Beginners might find online tutorials helpful, offering step-by-step guidance on how to start laser engraving stainless and achieving professional results.

Conclusion

Laser engraving stainless steel is an art and science that demands precision, skill, and the right technology. Machines like the LaserPecker LX1 Series represent the pinnacle of modern capability, offering features and performance that cater to a diverse range of needs. Whether you’re a hobbyist or a professional, understanding the aspects of laser engraving technology, machine specifications, and industry practices will undoubtedly enhance your craft. Investing in such innovation is not just about the tangible outputs; it’s about embracing the future of creativity and precision.

Have questions about laser engraving stainless or need more information on choosing the right machine for your projects? Feel free to explore further resources or contact an expert to guide your journey into this exciting field.