Title: Master Laser Cutting Plywood: Precision, Tips, and Project Ideas

Introduction

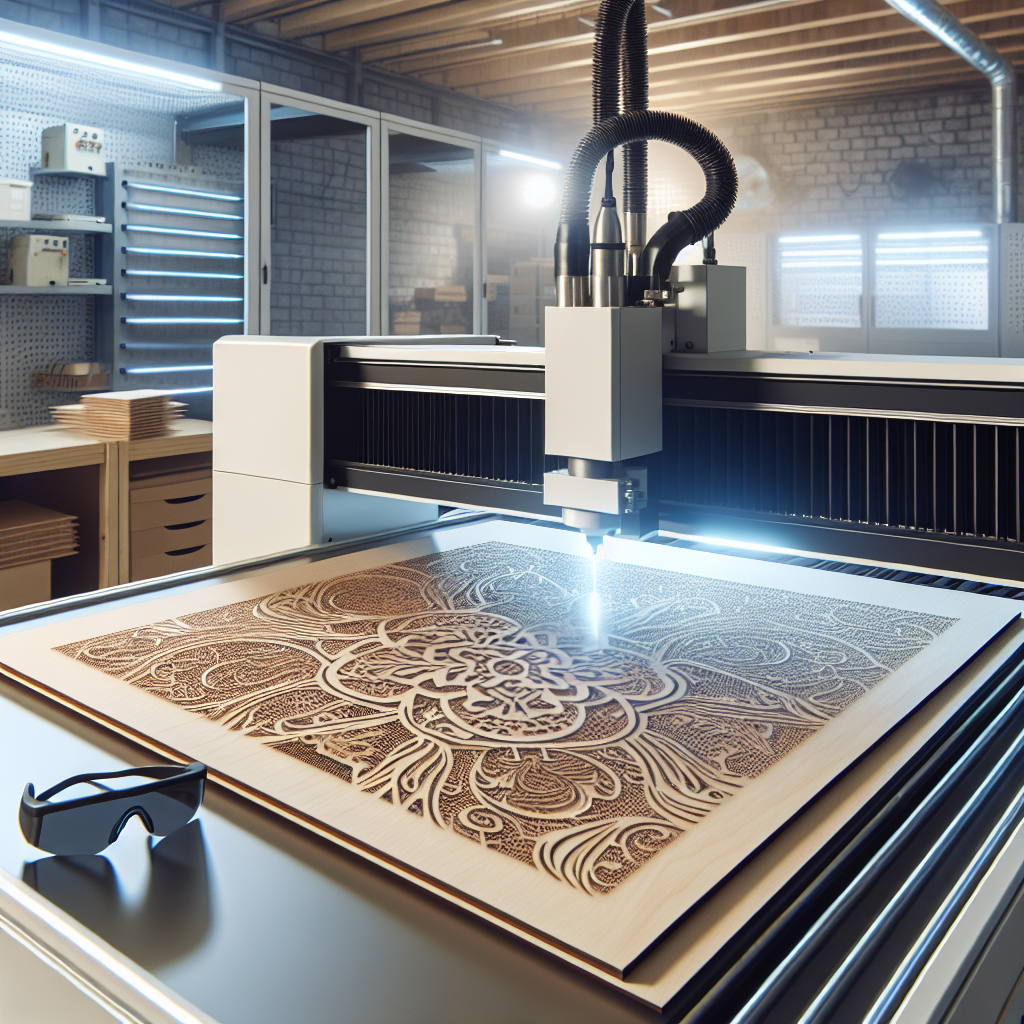

Laser engraving technology has significantly evolved, providing users from hobbyists to professional manufacturers the ability to create precise and intricate designs on various materials. Among these, laser cutting plywood stands out as one of the most popular applications. This article delves into the world of laser engraving machines, focusing on their application in plywood cutting, offering insights into machine specifications, material compatibility, safety considerations, and much more.

Understanding Laser Engraving Technology

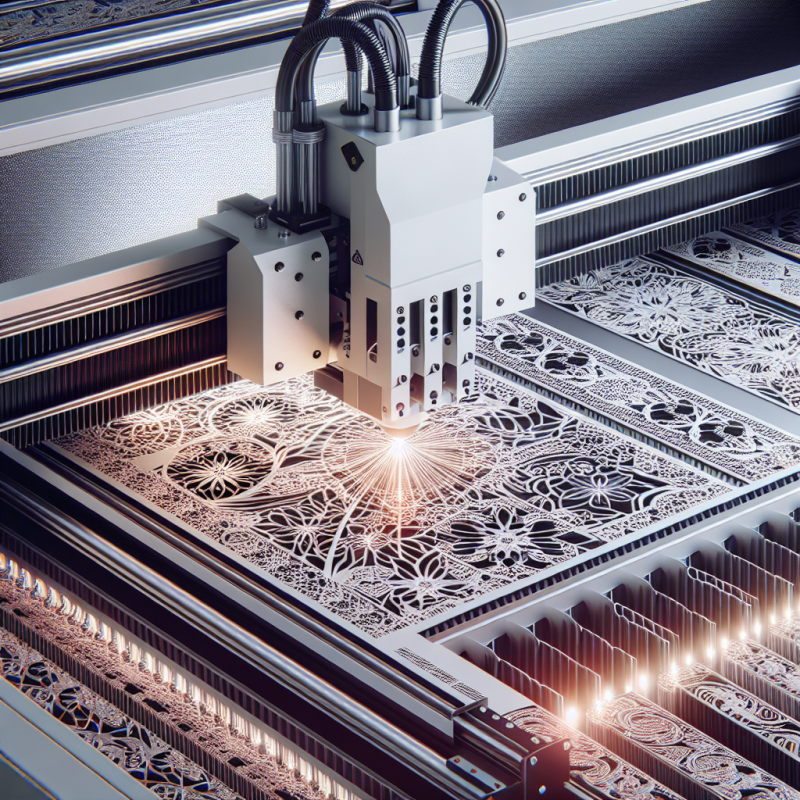

Laser engraving technology utilizes high-powered laser beams to cut or engrave materials. When it comes to laser cutting plywood, the laser beam applies intense heat to the plywood, vaporizing it in the process and leaving behind a clean cut or intricate design. This technology is praised for its precision, efficiency, and versatility, making it suitable for various applications such as artistic projects, architectural models, and customized gifts. Laser engraving allows for the production of complex designs that would be challenging to achieve with manual tools.

Key Features of Laser Engraving Machines

Modern laser engraving machines come equipped with a variety of features that enhance their usability and precision. When shopping for a laser engraver for laser cutting plywood, it’s essential to consider the following specifications:

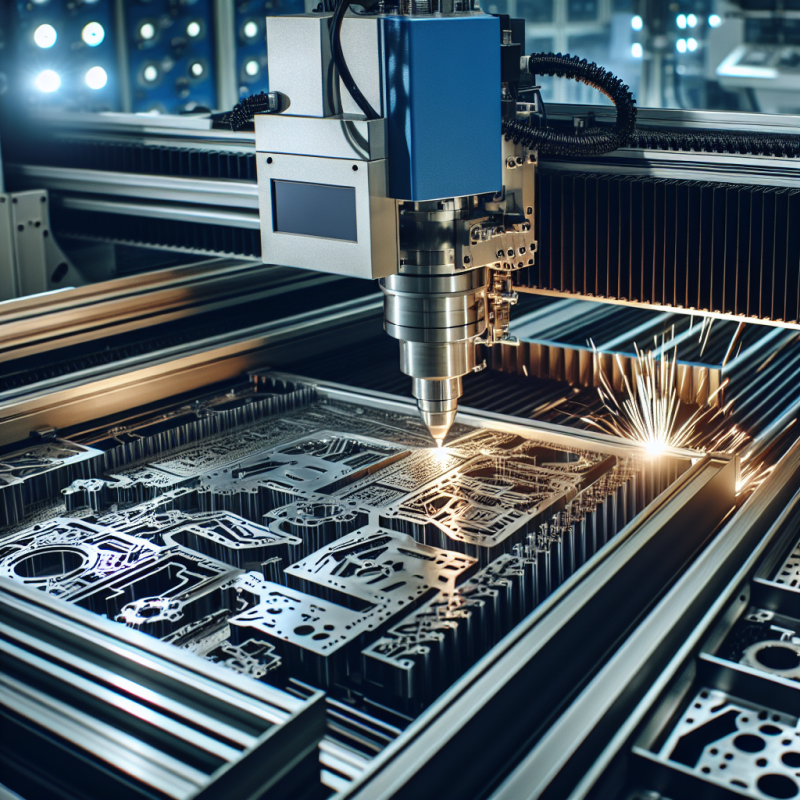

- Laser Power: The power of the laser, measured in watts, determines the machine’s ability to cut through materials. Higher wattages can cut through thicker plywood more effectively.

- Cutting Area: The size of the working area dictates the maximum dimensions of the material you can work with.

- Speed: Laser machines offer adjustable speed settings that affect the cutting and engraving process. Faster speeds result in quicker jobs but may compromise precision.

- Resolution: This refers to the density of the laser dots and is typically measured in DPI (dots per inch). Higher DPI results in finer and more detailed engravings.

- Software Compatibility: Most laser engraving machines come with their own software, but it’s crucial to check compatibility with other design software you might prefer.

Plywood as a Material for Laser Cutting

Plywood is a favored material for laser engraving because of its availability, affordability, and ease of work. However, not all laser machines are equally proficient at cutting plywood. When selecting a machine for laser cutting plywood, it’s crucial to consider the type and thickness of the plywood you plan to use:

- Softwood Plywood: This type engraves and cuts relatively easily due to its softer composition.

- Hardwood Plywood: Requires a more powerful laser due to its denser structure.

- Composite or Laminated Plywood: This material can be more challenging to work with due to the glue and layers, which may require specific settings and more power.

The thickness of the plywood also plays a significant role in the laser cutting process, as thicker material requires more power and may necessitate multiple passes for a clean cut.

Ensuring Safety During the Laser Cutting Process

Safety is a crucial aspect of working with laser cutting plywood. Here are some guidelines to ensure safe operation:

- Wear Safety Glasses: Protect your eyes from the intense laser light, which can cause serious damage.

- Ventilation: Ensure proper ventilation in your workspace to avoid inhaling fumes produced during laser cutting.

- Fire Safety: Always have a fire extinguisher nearby as laser beams can ignite certain materials if not monitored properly.

- Proper Machine Maintenance: Regularly clean and maintain your laser engraver to avoid malfunctions that could lead to accidents.

Best Practices for Laser Cutting Plywood

To achieve the best results when laser cutting plywood, adhere to these industry best practices:

- Test your settings on a scrap piece of plywood before committing to your final design. This helps to fine-tune speed and power settings for optimal cuts.

- Use masking tape on the surface of the plywood to prevent scorch marks and ensure clean edges.

- Keep the lens of the laser engraver clean to maintain precision and prevent energy loss during the cutting process.

- Consider using jigs or fixtures to hold your material securely and ensure consistent results, especially when working on multiple pieces.

Cautions Regarding Costs and Benefits

Investing in a laser engraver for laser cutting plywood can be a significant expense. Therefore, it’s essential to weigh the costs against the benefits:

- Initial Investment: High-quality laser engravers can be pricey, ranging from a few hundred to several thousand dollars.

- Operational Costs: Consider the costs of materials, maintenance, and electricity.

- Time Efficiency: Laser cutting can save time compared to manual methods, allowing for quicker project completion and higher productivity.

- Quality and Precision: The level of detail and accuracy achievable with a laser engraver often justifies the cost, especially for professional use.

Ultimately, the benefits of precision, efficiency, and versatility often outweigh the costs, making laser engraving a valuable investment for both hobbyists and professionals.

Proper Maintenance for Longevity

Maintaining your laser engraver is critical to ensuring its longevity and optimal performance. Here are some tips for proper maintenance:

- Regularly clean the laser lens and mirrors to prevent dust buildup, which can affect the precision and efficiency of the laser beam.

- Lubricate mechanical components to avoid wear and tear and ensure smooth operation.

- Check for software updates from the manufacturer to keep your machine running smoothly and to access new features and improvements.

- Inspect the cooling system regularly, as lasers generate significant heat which needs to be dissipated effectively to avoid damage.

Inspiring Project Ideas and Tutorials

To get started with laser cutting plywood, consider these project ideas and tutorials:

- Creating customized coasters with intricate designs to add a personal touch to your home decor.

- Designing and cutting detailed architectural models for school projects or professional presentations.

- Producing personalized wooden signs as gifts or for event branding.

- Engraving unique art pieces to sell online or at local markets.

There are numerous online resources and communities where you can find detailed tutorials, project inspirations, and support from fellow laser engraving enthusiasts. Engaging with these communities can enhance your skills and expand your creative horizons.

Frequently Asked Questions About Laser Engraving

Here are some commonly asked questions that potential users have about laser engraving machines:

- What materials can I cut and engrave with a laser machine? – Besides plywood, laser engravers can work with materials such as acrylic, leather, fabric, paper, and certain metals.

- How do I choose the right laser engraver for my needs? – Consider factors like laser power, cutting area, speed, resolution, and software compatibility based on your specific projects and material requirements.

- Are laser engravers safe to use at home? – Yes, they can be safe with proper safety measures, such as wearing protective glasses, ensuring adequate ventilation, and maintaining the machine regularly.

- How do I maintain my laser engraver? – Routine cleaning, lubricating mechanical parts, checking for software updates, and inspecting the cooling system are essential maintenance tasks.

- Can I use a laser engraver for mass production? – Yes, with the right settings and jigs, laser engravers can efficiently handle mass production while maintaining high-quality results.

Conclusion

Laser cutting plywood is a precise and versatile method for both DIY enthusiasts and professionals. With the right machine, knowledge, and safety measures, you can create intricate and high-quality designs efficiently. Investing in a laser engraver not only enhances your creative capabilities but also opens up numerous possibilities for personal and commercial projects. Always remember to prioritize safety, stay updated with best practices, and regularly maintain your equipment for the best results.