Mastering Laser Engraving Wood: A Comprehensive Guide

Laser engraving wood is a versatile and precise method that has revolutionized woodworking and craft projects. With the advent of modern technology, laser engravers have become more accessible, allowing hobbyists and professionals alike to create intricate designs with ease. In this article, we will explore everything you need to know about laser engraving wood, from its advantages to step-by-step guides and troubleshooting tips.

What is Laser Engraving Wood?

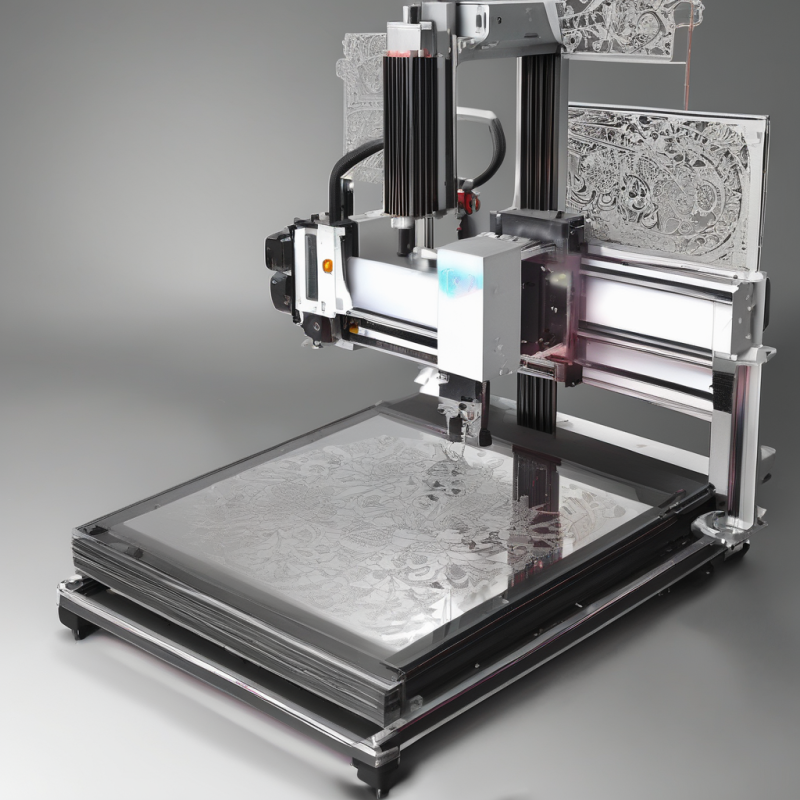

Laser engraving wood involves using a laser beam to create permanent markings on wooden surfaces. Unlike traditional methods that rely on mechanical cutting or burning, laser engraving offers unparalleled precision and detail. The process uses focused light energy to remove material, resulting in clean, smudge-free engravings that are resistant to fading over time.

If you’re wondering how laser engraving wood works, the basic principle involves directing a high-powered laser beam at the wood surface. The laser heats the wood fibers, causing them to vaporize or char, which creates the desired design. This method is not only faster but also produces more accurate results compared to manual carving methods.

Advantages of Laser Engraving Wood

Laser engraving wood has numerous benefits that make it a preferred choice for many crafters and manufacturers:

- Precision and Detail: Laser engravers can create intricate designs with hairline precision, making them ideal for fine art and detailed patterns.

- Versatility: Suitable for various types of wood, including hardwoods like oak and softwoods like pine.

- Durability: Engravings are resistant to wear and tear, ensuring long-lasting results.

- Customization: Easy to customize designs using computer software, allowing for infinite creative possibilities.

If you’re considering laser engraving wood, these advantages make it a compelling choice for both small-scale projects and large-scale production.

Choosing the Right Laser Engraver for Wood

Selecting the right laser engraver is crucial for achieving optimal results. Factors to consider include power, portability, and compatibility with different wood types. For instance, a portable laser engraver like the one available at laser engraving wood can be a great option for hobbyists who need flexibility.

When choosing your equipment, consider the following:

- Power Output: Higher power lasers are better suited for thicker or harder woods.

- Focal Length: Shorter focal lengths are ideal for detailed work, while longer ones are better for larger areas.

- Safety Features: Ensure the engraver includes safety features like emergency stop buttons and protective enclosures.

Investing in a quality laser engraver will not only enhance your projects but also ensure safer operation. If you’re looking for a reliable tool, check out the laser engraving wood product.

Step-by-Step Guide to Laser Engraving Wood

Whether you’re a novice or an experienced crafter, mastering laser engraving wood requires attention to detail and practice. Here’s a step-by-step guide to help you get started:

- Select Your Design: Use computer-aided design (CAD) software to create or import your design. Ensure the design is suitable for laser engraving by checking for compatibility with wood surfaces.

- Prepare the Wood: Sand the wood surface to a smooth finish and ensure it’s free from dust and debris. Proper preparation enhances the engraving quality.

- Set Up the Laser Engraver: Follow the manufacturer’s instructions to calibrate your laser engraver, adjusting settings like power level and speed based on the wood type and design complexity.

- Engrave Your Design: Load the wood into the engraver, secure it properly, and initiate the engraving process. Monitor the machine to ensure everything runs smoothly.

- Finish Touches: Once the engraving is complete, remove any residual material with compressed air or a soft brush. Apply a protective finish if desired to enhance durability.

By following these steps, you can create stunning laser-engraved wood projects that showcase your creativity and craftsmanship.

Troubleshooting Common Issues in Laser Engraving Wood

Like any technology, laser engraving wood may encounter challenges. Here are some common issues and solutions:

- Uneven Engravings: Ensure the wood is evenly placed on the engraver bed and adjust the focal length for optimal results.

- Burn Marks: Reduce the laser power or increase the speed to prevent over-burning. Experiment with different settings to find the right balance.

- Fine Details Not Showing Up: Use a higher-resolution design file and ensure the laser is properly focused for intricate patterns.

If you’re encountering persistent issues, consult your engraver’s user manual or seek advice from online communities. Remember, practice makes perfect!

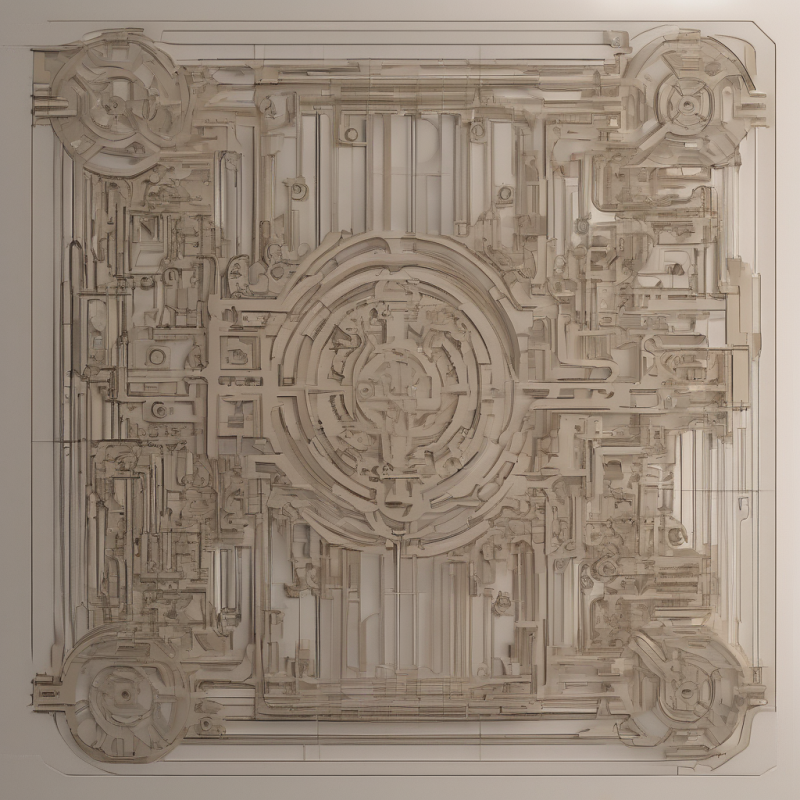

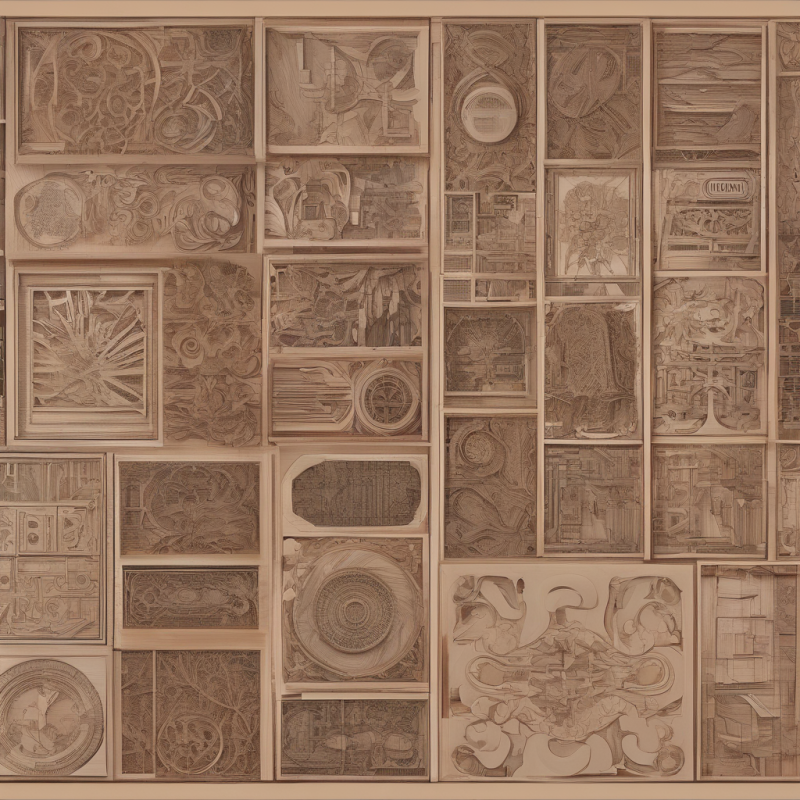

Creative Applications of Laser Engraving Wood

Laser engraving wood opens up a world of creative possibilities. Here are some inspiring ideas to spark your imagination:

- Custom Furniture: Add unique designs or family crests to tables, chairs, and other furniture pieces.

- Jewelry Boxes: Engrave personalized messages or patterns on wooden jewelry boxes for a custom touch.

- Signage: Create professional-looking signs with detailed lettering and motifs.

- Art Pieces: Use laser engraving to create one-of-a-kind artistic masterpieces that combine form and function.

Limited only by your creativity, laser engraving wood allows you to bring your ideas to life with precision and style.

Safety Tips for Laser Engraving Wood

While laser engraving wood is a safe process when handled correctly, it’s essential to follow these safety guidelines:

- Protect Your Eyes: Always wear proper eye protection, as lasers emit bright light that can be harmful.

- Ventilate the Area: Laser engraving produces fumes and particles; ensure adequate ventilation or use a dust extraction system.

- Handle with Care: Follow all manufacturer safety instructions and handle the laser engraver with care to prevent accidents.

Prioritizing safety ensures you can enjoy your laser engraving projects without risks.

Frequently Asked Questions About Laser Engraving Wood

If you’re new to laser engraving wood, here are answers to some common questions:

- Can I engrave on any type of wood? Most types of wood can be laser engraved, but softer woods may require lower power settings.

- Do I need special software for design? Yes, you’ll need CAD or vector graphics software to create designs compatible with your laser engraver.

- How long does a laser engraving project take? The time varies depending on the complexity of the design and the size of the wood piece. Simple projects can be completed in minutes, while intricate designs may take longer.

If you have more questions, refer to your engraver’s manual or seek advice from experienced users online.

Conclusion

Laser engraving wood is a fascinating and rewarding craft that combines technology with creativity. With the right equipment, techniques, and safety precautions, you can produce stunning engravings that showcase your skills and imagination. Whether you’re creating custom furniture, signage, or unique art pieces, laser engraving wood offers endless possibilities for your projects.

Remember to always follow safety guidelines and experiment with different designs to refine your technique. Happy engraving!