Mastering Woodcraft: How a Laser Cutter for Wood Transforms Your Projects

Crafting with precision has never been easier, thanks to modern technology. Whether you’re a hobbyist or a professional woodworker, a laser cutter for wood can elevate your projects to new heights. This article explores the benefits, applications, and essential features of this versatile tool, answering common questions along the way. Let’s dive into the world of laser cutting and discover how it can transform your woodworking experience.

What is a Laser Cutter for Wood?

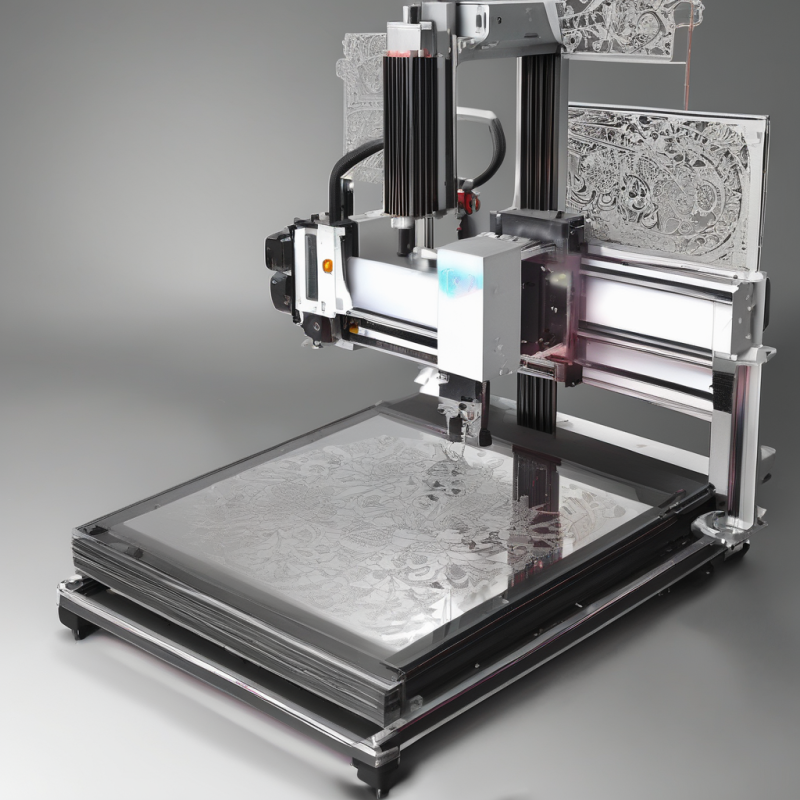

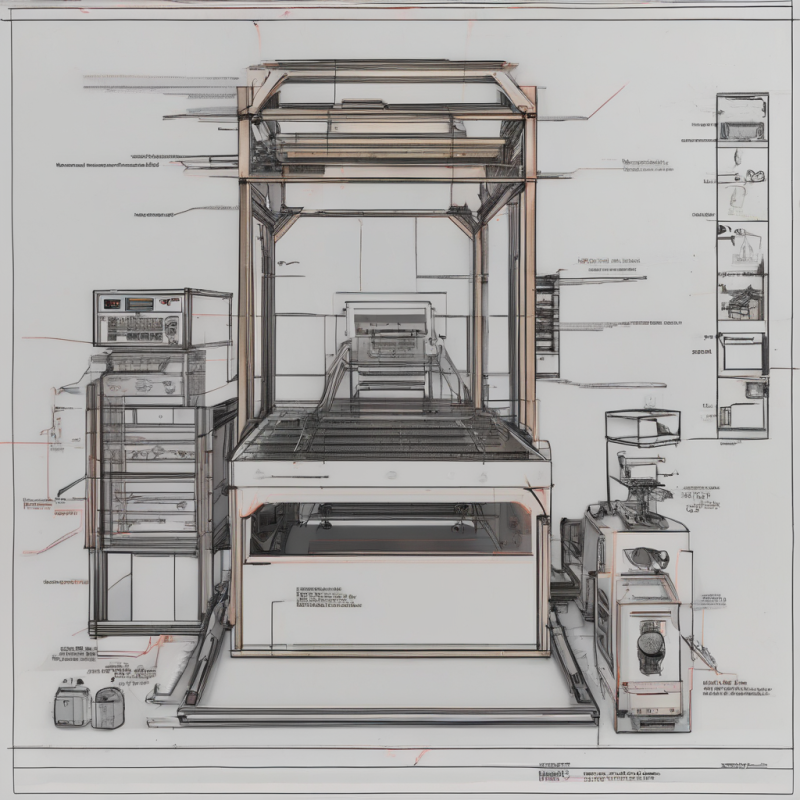

A laser cutter for wood is a precision tool that uses a focused beam of light to cut, engrave, or etch materials like wood. Unlike traditional cutting methods, which rely on physical blades, laser cutters offer unparalleled accuracy and flexibility. The process involves directing a high-powered laser at the material, melting, burning, or vaporizing it to create precise designs. This technology is ideal for intricate patterns, custom engravings, and clean cuts that are difficult to achieve manually.

If you’re wondering, “What makes a laser cutter for wood different from other tools?”—the answer lies in its precision, speed, and ability to handle complex designs with ease. Whether you’re creating decorative items, furniture, or personalized gifts, a laser cutter can streamline your workflow and produce professional-quality results.

Benefits of Using a Laser Cutter for Wood

The advantages of using a laser cutter for wood are numerous, making it a must-have tool for any serious craftsperson. Here are some key benefits:

- Precision and Accuracy: Laser cutters can achieve intricate details with micron-level precision, ensuring every cut or engraving is flawless.

- Speed: Compared to manual cutting methods, laser cutters significantly reduce production time while maintaining quality.

- Versatility: They work with various materials, including wood, acrylic, leather, and even glass, making them a versatile addition to any workshop.

- Non-Contact Process: Since there’s no physical contact during cutting, the risk of material damage or warping is minimized.

These benefits make a laser cutter for wood an indispensable tool for both small-scale projects and large-scale manufacturing. Whether you’re creating custom furniture, signage, or decorative items, this technology can help you achieve your vision with ease.

Key Features to Look For in a Laser Cutter for Wood

When selecting a laser cutter for wood, it’s essential to consider its specifications and features. Here are some key factors to keep in mind:

- Laser Power: Higher power lasers can handle thicker materials and faster cutting speeds, but they may require more advanced safety precautions.

- Cutting Speed: Look for a machine that balances speed with accuracy to ensure efficient production without compromising quality.

- Software Compatibility: Ensure the laser cutter is compatible with popular design software like Adobe Illustrator or CorelDRAW for seamless workflow integration.

- Build Quality: Invest in a machine with robust construction and durable components to ensure long-term reliability.

If you’re asking, “What makes one laser cutter stand out from another?”—the answer often lies in these key features. By prioritizing them, you can find a machine that meets your specific needs and budget.

How Does a Laser Cutter for Wood Work?

Understanding the mechanics of a laser cutter for wood can help you use it more effectively. The process typically involves the following steps:

- Design Creation: Create or import your design into compatible software.

- Laser Alignment: Position the material under the laser head and ensure proper alignment.

- Cutting/Engraving: The laser beam targets specific points on the material, melting or vaporizing it to create precise cuts or engravings.

- Post-Processing: Clean and finish the final product as needed.

This process is quick, efficient, and requires minimal setup, making it ideal for both small-scale projects and large-scale production. With a laser cutter for wood, you can take your woodworking to the next level with ease.

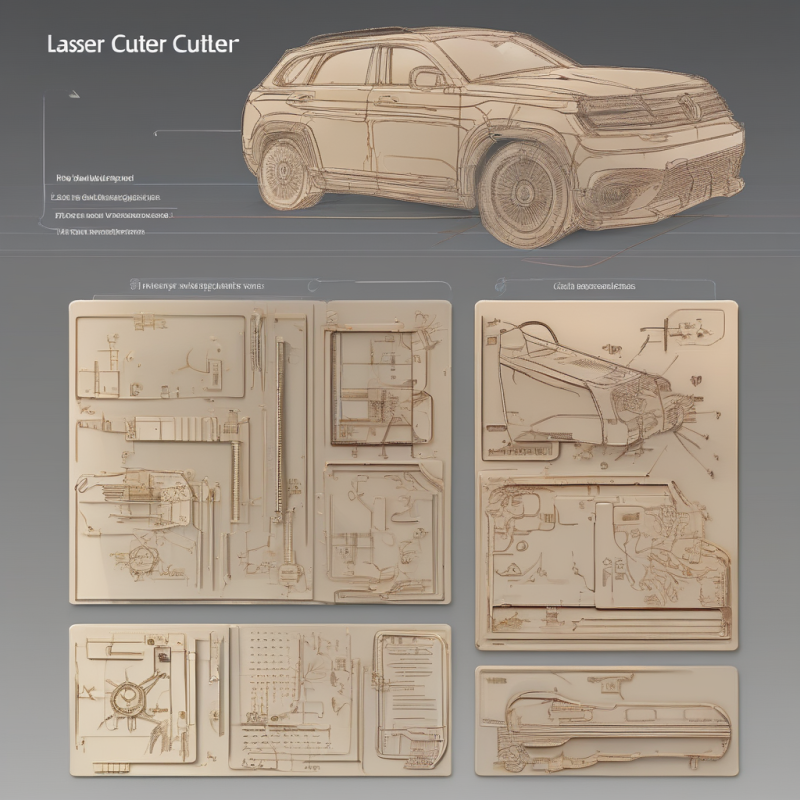

Applications of a Laser Cutter for Wood

The applications of a laser cutter for wood are virtually endless, making it a valuable tool for artists, craftsmen, and manufacturers alike. Some popular uses include:

- Custom Engravings: Add personalized designs or text to wooden items like furniture, jewelry boxes, or decorative panels.

- Puzzle Making: Create intricate jigsaw puzzles with precision-cut pieces.

- Furniture Production: Cut and shape components for custom furniture with ease.

- Signage Creation: Produce professional-looking signs, plaques, and displays with detailed engravings.

These applications demonstrate the versatility of a laser cutter for wood, making it a valuable tool for any workshop or production facility.

Maintenance and Safety Tips for Laser Cutters

To ensure optimal performance and longevity, proper maintenance and safety practices are essential when using a laser cutter for wood. Here are some tips:

- Regular Cleaning: Keep the machine clean to prevent dust or debris buildup, which can affect performance.

- Lens Care: Clean the laser lenses regularly to maintain beam quality and efficiency.

- Safety Protocols: Always wear appropriate safety gear, including goggles and gloves, when operating the machine.

- Proper Ventilation: Ensure adequate ventilation to avoid inhaling harmful fumes produced during cutting or engraving.

By following these guidelines, you can maximize the lifespan of your laser cutter for wood while maintaining a safe and efficient workspace.

Frequently Asked Questions About Laser Cutters for Wood

If you’re new to laser cutting technology, you may have several questions. Here are some common ones:

- Can I use a laser cutter on different materials besides wood? Yes! Most laser cutters can work with various materials like acrylic, leather, and glass, depending on the machine’s specifications.

- Is it safe to operate a laser cutter? With proper safety precautions, such as wearing protective gear and ensuring good ventilation, operating a laser cutter is relatively safe.

- How much does a laser cutter cost? Prices vary depending on the machine’s power, size, and features. Entry-level models can range from $1,000 to $5,000, while industrial-grade machines may cost upwards of $20,000.

- What software do I need to use a laser cutter? Most machines are compatible with popular design software like Adobe Illustrator, CorelDRAW, or Inkscape. Some also come with proprietary software for easier operation.

These answers should help you better understand the capabilities and requirements of a laser cutter for wood.

Conclusion

A laser cutter for wood is a powerful tool that can transform your woodworking projects into works of art. Its precision, speed, and versatility make it an invaluable addition to any workshop or production facility. Whether you’re creating custom engravings, intricate puzzles, or high-quality furniture, this technology can help you achieve professional results with ease.

If you’re ready to take your woodworking to the next level, consider investing in a laser cutter for wood. With proper maintenance and safety practices, it will serve as a reliable tool for years to come. Happy crafting!

Laser Cutter for Wood: A Comprehensive Guide

In the realm of woodworking and craft creation, few tools offer the precision and versatility of a laser cutter. This guide explores the capabilities, benefits, applications, and maintenance tips for using a laser cutter on wood.

Understanding Laser Cutters for Wood

A laser cutter uses high-powered lasers to cut or engrave materials like wood by melting, burning, or vaporizing them. This non-contact method ensures clean, precise cuts without physical damage to the material.

Key Benefits:

– Precision and Accuracy: Achieve intricate designs with micron-level accuracy.

– Speed: Significantly reduces production time compared to manual methods.

– Versatility: Works with various materials including wood, acrylic, leather, and glass.

– Non-Contact Process: Minimizes material damage or warping.

Choosing the Right Laser Cutter

When selecting a laser cutter, consider:

– **Laser Power:** Higher power handles thicker materials but requires safety precautions.

– **Cutting Speed:** Balance speed with accuracy for efficient production.

– **Software Compatibility:** Ensure compatibility with design software like Adobe Illustrator.

– **Build Quality:** Opt for robust construction for long-term reliability.

How It Works

1. **Design Creation:** Create or import designs into compatible software.

2. **Laser Alignment:** Position the material and ensure proper alignment.

3. **Cutting/Engraving:** The laser targets specific points, melting or vaporizing the material.

4. **Post-Processing:** Clean and finish the final product.

Applications

– **Custom Engravings:** Personalize items like furniture or jewelry boxes.

– **Puzzle Making:** Create detailed puzzles with precision.

– **Signage and Displays:** Produce high-quality signs and promotional materials.

– **Furniture Production:** Craft intricate designs for a polished finish.

Maintenance and Safety Tips

– **Regular Cleaning:** Prevent dust buildup to maintain performance.

– **Lens Care:** Clean lenses regularly to ensure beam quality.

– **Safety Protocols:** Wear protective gear, including goggles and gloves.

– **Proper Ventilation:** Ensure good airflow to avoid inhaling fumes.

FAQs

1. **Compatibility:** Can work with various materials beyond wood.

2. **Safety:** Safe operation with proper precautions.

3. **Cost:** Varies widely; entry-level models start around $1,000.

4. **Software Needs:** Compatible with popular design software and may include proprietary options.

Conclusion

A laser cutter for wood is a transformative tool for any workshop or production facility. Its precision and versatility make it ideal for creating custom engravings, intricate puzzles, and high-quality furniture. By adhering to maintenance and safety practices, this investment will yield years of reliable service, elevating your woodworking projects to new heights.

Happy Crafting!