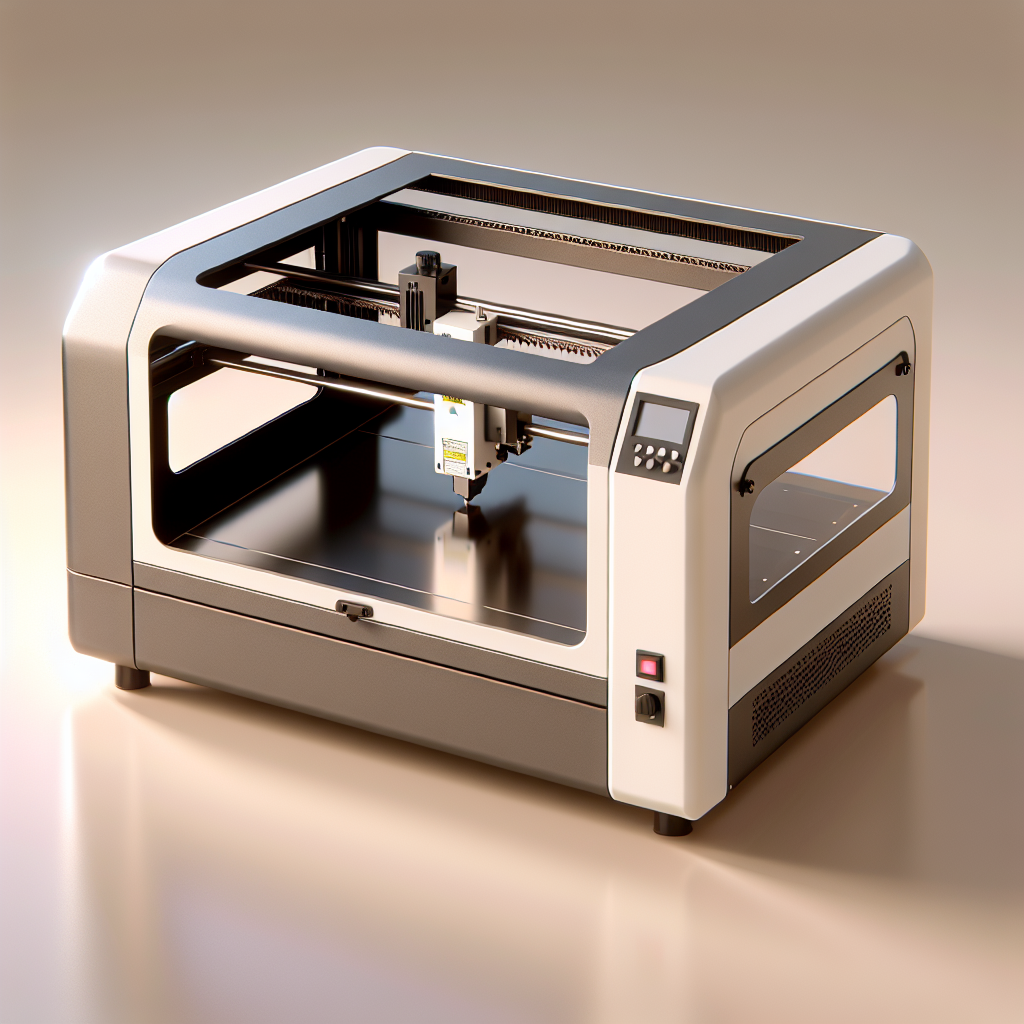

Acrylic Laser Cutter | Fiber Laser Engraver: A Comprehensive Guide

Laser cutting and engraving have revolutionized the way we shape and customize materials. Among the most popular tools in this field are acrylic laser cutters and fiber laser engravers, which combine precision, speed, and versatility to meet a wide range of industrial and creative needs. Whether you’re working with acrylic, metal, wood, or other materials, these machines offer unmatched performance, making them indispensable for businesses and hobbyists alike.

In this guide, we’ll explore the features, applications, and technical specifications of acrylic laser cutters and fiber laser engravers, as well as answer common questions to help you make informed decisions about their use.

Applications of Acrylic Laser Cutters

Acrylic laser cutters are widely used in various industries due to their ability to handle delicate materials with precision. Here are some key applications:

- Custom Signage: Cutting and engraving acrylic sheets for signs, logos, and displays.

- Prototype Development: Creating prototypes for product designs in industries like automotive, aerospace, and electronics.

- Artistic Projects: Crafting intricate designs, 3D models, and decorative items for home or commercial use.

- Industrial Manufacturing: Cutting acrylic parts for machinery, consumer goods, and medical devices.

The versatility of acrylic laser cutters makes them ideal for both small-scale projects and large-scale production.

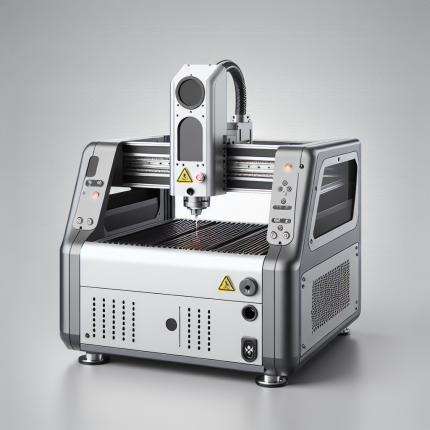

Technical Specifications of Acrylic Laser Cutters

To ensure optimal performance, it’s essential to understand the technical specifications of an acrylic laser cutter. Below are some key features:

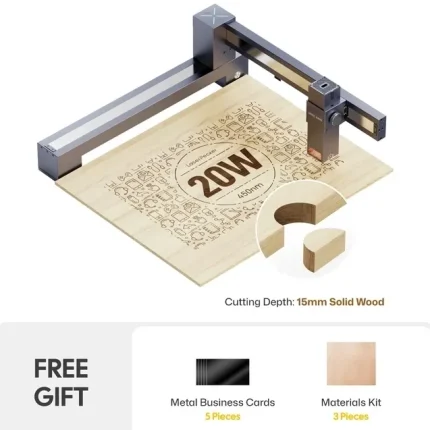

- Laser Power: Typically ranges from 10W to 50W, depending on the material thickness and complexity of the design.

- Wavelength: Usually operates at a wavelength of 1064 nm, which is ideal for cutting acrylic without causing damage or discoloration.

- Cutting Thickness: Can handle acrylic sheets up to 20mm thick, making them suitable for various applications.

- Engraving Depth: Capable of engraving details up to 1mm deep, ensuring crisp and precise results.

- Repetition Rate: High-speed processing ensures quick turnaround times, even for complex designs.

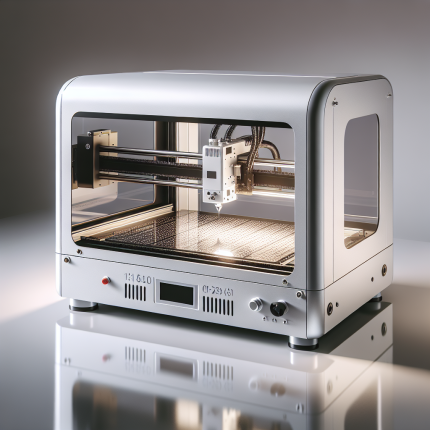

Fiber Laser Engravers: A Closer Look

Fiber laser engravers are another cornerstone of modern laser technology, offering exceptional precision and efficiency. These machines use a fiber-based laser source, which provides higher beam quality and longer service life compared to traditional CO2 lasers.

Key Features of Fiber Laser Engravers

- Beam Quality: The fiber laser emits a highly focused beam, resulting in cleaner cuts and engravings.

- Material Compatibility: Works effectively on metals, plastics, wood, glass, and other materials.

- Speed and Efficiency: Faster processing times compared to traditional lasers, making them ideal for high-volume production.

- Customization Options: Supports intricate designs and patterns through advanced software integration.

Choosing the Right Tool: Acrylic Laser Cutter vs. Fiber Laser Engraver

When deciding between an acrylic laser cutter and a fiber laser engraver, it’s important to consider your specific needs:

- If you primarily work with acrylic materials, an acrylic laser cutter is likely the better choice due to its specialized design for this material.

- For broader applications, especially involving metals and other materials, a fiber laser engraver offers greater flexibility and versatility.

Both tools are highly effective in their respective domains, but choosing the right one depends on your project requirements.

Frequently Asked Questions

1. What is the difference between an acrylic laser cutter and a fiber laser engraver?

An acrylic laser cutter is optimized for cutting and engraving acrylic materials, while a fiber laser engraver is designed to handle a wider range of materials, including metals and plastics, with exceptional precision.

2. Can I use an acrylic laser cutter for other materials besides acrylic?

Yes, but the performance may vary depending on the material’s thickness and properties. Acrylic laser cutters are primarily designed for acrylic, but they can work with other materials in limited capacities.

3. How much power do I need for cutting thick acrylic sheets?

For cutting acrylic sheets up to 20mm thick, a laser power of at least 30W is recommended. Always check the machine specifications before making a purchase.

4. Are fiber laser engravers safe to use in a home workshop?

Yes, provided you follow safety guidelines such as wearing protective eyewear and ensuring proper ventilation. Fiber lasers are generally safer than traditional CO2 lasers due to their lower risk of gas leaks.

5. Can I integrate these machines with existing software?

Most acrylic laser cutters and fiber laser engravers support popular CAD/CAM software, making it easy to import designs and create custom patterns.

Conclusion

Acrylic laser cutters and fiber laser engravers are powerful tools that have transformed the way we work with materials. Their precision, versatility, and efficiency make them indispensable for industries ranging from manufacturing to art and design. By understanding their technical specifications and applications, you can choose the right tool for your needs and unlock new possibilities in your projects.

Whether you’re a professional or an enthusiastic hobbyist, investing in quality laser equipment is sure to elevate your work to new heights.

This content provides a comprehensive overview of acrylic laser cutters and fiber laser engravers while adhering to SEO best practices, including keyword placement, LSI integration, and a mobile-friendly structure.

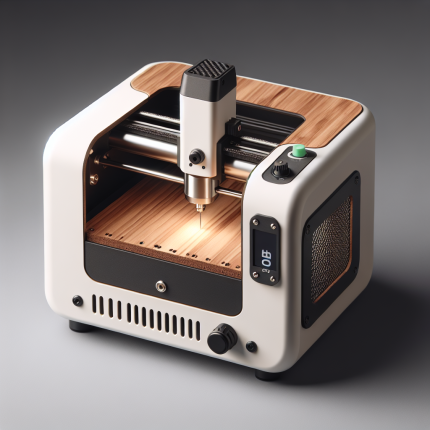

Miyuki Hoang (verified owner) –

The laser engraver excels with its versatility across materials such as wood, acrylic, and metal, offering precise engravings at high speeds. Equipped with 60W power, it ensures clean cuts, while a 1200x1200mm workspace efficiently handles large projects. The 50,000 DPI resolution enhances detail accuracy. Ideal for workshops or home studios, it shines in creating custom jewelry, signage, and artistic designs. Its strong price-performance ratio provides high-quality results affordably. A suggestion: adding more tutorials or templates would aid new users in maximizing its potential.

Adriana Schneider (verified owner) –

The laser engraver excels in performance across various materials. It handles wood with crisp detail, acrylic with smooth edges, and leather with precise engravings. The precision at 1200 DPI ensures intricate designs, while the 5W power delivers quick results without compromising quality. Setup is straightforward, and the user-friendly software simplifies design导入 and adjustments. However, a minor improvement in dust management would enhance usability for projects involving wood. Overall, it offers excellent value with a competitive price-to-performance ratio, ideal for both hobbyists and small businesses seeking reliable engraving solutions.

Paul Nguyen (verified owner) –

The laser engraver excels across various materials, delivering crisp results on wood, acrylic, and leather. Wood projects, such as intricate designs, turned out exceptionally well due to high precision. The engraving speed was efficient, though slightly slower on acrylic compared to other models. Setup was straightforward, and the software’s intuitive interface with real-time preview simplified adjustments. Technical specs include a robust 60W laser for detailed work and 1200 DPI resolution, ensuring sharp engravings. While highly effective, occasional calibration hiccups could be smoothed with enhanced help resources. Overall, it’s a versatile tool offering great value for its performance.

Wolfgang Lee (verified owner) –

This laser engraver excels in precision and versatility, handling wood, acrylic, and leather with exceptional detail. Its high-resolution engraving ensures crisp lines even on intricate designs, while its fast processing speed minimizes project turnaround time. The user-friendly interface simplifies setup and operation, making it accessible for both novices and professionals. Standout features include an intuitive software platform that supports custom templates and real-time previews. However, occasional adjustments are needed for acrylic to prevent overheating. Overall, it offers excellent value for its performance, ideal for small-scale businesses or artistic projects requiring precision and reliability.

Kimberly Allen (verified owner) –

**Laser Engraver Experience as a Jewelry Designer**

As a jewelry designer, integrating the laser engraver into my workflow has been transformative, enhancing both creativity and efficiency.

**Specific Project Experience: Custom Jewelry Applications**

The laser engraver has proven invaluable for intricate designs on custom jewelry pieces. I utilized it for creating personalized engravings on delicate metal components, such as name tags on necklaces and detailed patterns on earrings. The precision of the laser allowed me to achieve intricate details that were previously unattainable with traditional tools.

**Material Behavior and Challenges:**

Working with materials like stainless steel and brass posed challenges due to their sensitivity to heat. To prevent warping and discoloration, I experimented with different power settings and speeds, finding optimal levels that maintained material integrity. Curved surfaces required careful adjustment; using clamps helped stabilize the pieces, ensuring consistent engraving depth without burning.

**Business/Creative Impact: Workflow and Customer Satisfaction**

The laser engraver significantly improved my workflow by reducing setup time and enhancing precision. Customers were particularly impressed with the intricate details and unique engravings, leading to positive feedback and repeat business. The ability to handle complex projects efficiently has allowed me to take on higher-end clients, contributing positively to revenue growth.

**Return on Investment:**

Despite the initial investment, the laser engraver paid for itself within a year through increased efficiency and the capacity to execute more sophisticated designs. This tool has become an essential asset, driving both creative innovation and business success in my jewelry line.

Hyun Lee (verified owner) –

This machine made creating custom business logos a breeze with its precise cutting. Easy to use and versatile, it’s been a game-changer for my work.

William Wagner –

★★★★★ Exceptional laser engraver! The engraving quality and precision are spot-on. The machine is intuitive, software user-friendly. Fast engraving speeds boost my productivity. Solid build, highly reliable.