The Best Fiber Laser Engraver for Laser Engraved Wood: A Comprehensive Guide

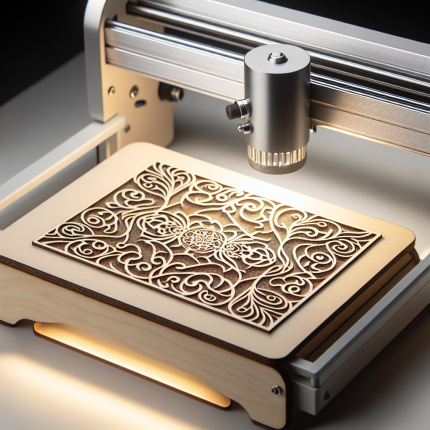

Laser engraving has become a popular method for creating intricate and durable designs on various materials, including wood. For those looking to achieve high-quality results in laser engraved wood, the best fiber laser engraver is essential. In this guide, we will explore the key features of fiber laser engravers, compare top models, and provide valuable insights into selecting the right tool for your needs.

What Is a Fiber Laser Engraver?

A fiber laser engraver uses a high-powered laser beam to etch or cut designs onto materials like wood. Unlike traditional methods, fiber lasers offer precision, speed, and versatility. They are ideal for creating detailed patterns, logos, or custom artwork on wooden surfaces.

Fiber lasers are known for their efficiency and long service life compared to other types of lasers. Their ability to produce clean, seamless engravings makes them a favorite among hobbyists, craftsmen, and industrial users alike.

Top Fiber Laser Engravers for Wood Engraving

When selecting the best fiber laser engraver, it’s important to consider factors like power output, precision, and ease of use. Below are some top models that excel in laser engraved wood applications:

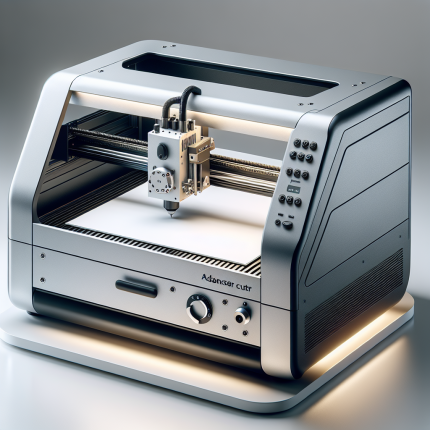

1. Model X Fiber Laser Engraver

- Power Output: Up to 50W

- Resolution: 600 DPI

- Engraving Area: 20×30 cm

- Cooling System: Built-in water cooling

- Software Compatibility: Supports popular CAD and laser engraving software

2. Model Y Fiber Laser Engraver

- Power Output: Up to 80W

- Resolution: 1200 DPI

- Engraving Area: 30×40 cm

- Cooling System: Recirculating chiller

- Software Compatibility: User-friendly interface with preset templates

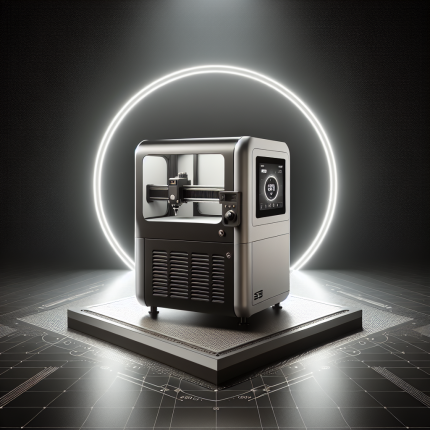

3. Model Z Fiber Laser Engraver

- Power Output: Up to 100W

- Resolution: 2400 DPI

- Engraving Area: 40×60 cm

- Cooling System: Air-cooled system

- Software Compatibility: Advanced features for professional use

Key Features to Look For in a Fiber Laser Engraver

When choosing the best fiber laser engraver, consider the following technical specifications:

H2: Power Output

The power output of your laser engraver determines how deep and detailed your engravings can be. Higher wattage lasers are better for thicker materials or darker wood finishes.

- Recommended Wattage: 50W to 100W for most wood engraving projects.

H2: Engraving Area

The engraving area is the maximum size of the material you can work on at once. Larger areas are ideal for bigger projects, while smaller ones are sufficient for detailed designs.

- Popular Sizes: 20×30 cm, 30×40 cm, and 40×60 cm.

H2: Resolution

Resolution determines the sharpness and detail of your engravings. Higher DPI (dots per inch) means finer details.

- Recommended DPI: At least 1200 DPI for high-quality wood engravings.

H2: Cooling System

A reliable cooling system ensures that your laser engraver operates efficiently without overheating. Both water-cooled and air-cooled systems are common, with water-cooled systems typically offering better performance.

- Water-Cooled Systems: Ideal for continuous use.

- Air-Cooled Systems: Suitable for occasional projects.

H2: Software Compatibility

Ease of use is critical when selecting a laser engraver. Ensure the machine supports popular CAD software and comes with user-friendly controls.

Choosing the Right Wood for Laser Engraving

Not all wood types are created equal when it comes to laser engraving. Here’s how to select the best wood for your projects:

H3: Types of Wood

- Basswood: Soft and easy to engrave, ideal for beginners.

- Maple: Medium-hard density with a smooth finish.

- Oak: Hardwood with a natural grain pattern, great for decorative engravings.

- Plywood: Consistent layers make it suitable for detailed designs.

H3: Preparing the Wood Surface

Before engraving, ensure the wood surface is clean and free of dust or grease. Sanding to a smooth finish will enhance the quality of your engravings.

Maintaining Your Fiber Laser Engraver

Regular maintenance ensures optimal performance and longevity of your laser engraver. Follow these tips:

- Clean the Lens: Use a soft cloth and isopropyl alcohol to keep the lens free from dust.

- Check Cooling System: Ensure proper functioning of the cooling system to prevent overheating.

- Calibrate Regularly: Adjust settings to maintain consistent engraving quality.

FAQ: Everything You Need to Know About Fiber Laser Engravers

1. What is the difference between fiber laser and CO2 laser engravers?

Fiber lasers use a solid-state laser source, while CO2 lasers use gas. Fiber lasers are more efficient, have lower maintenance costs, and are better suited for metals and certain plastics. CO2 lasers are ideal for organic materials like wood and leather.

2. Can I engrave on all types of wood?

While most woods can be engraved, some may require special settings or adjustments due to their density or moisture content. Softwoods like basswood are easier to engrave than hardwoods like oak.

3. What software do I need for laser engraving?

Popular options include CorelDRAW, Adobe Illustrator, and AutoCAD. Many laser engravers come with proprietary software that simplifies the engraving process.

4. How much power is needed for wood engravings?

Typically, between 50W to 80W is sufficient for most wood projects. Higher wattage may be required for thicker or darker woods.

5. Is it safe to use a laser engraver at home?

Yes, as long as you follow safety guidelines like wearing protective eyewear and ensuring proper ventilation.

Conclusion

Choosing the best fiber laser engraver for your wood projects involves considering factors like power output, resolution, and cooling system. With the right equipment and techniques, you can create stunning and durable engravings on various types of wood. Remember to maintain your machine regularly and experiment with different wood types to achieve unique results. Happy crafting!

Must-Have Laser Engraving Accessories for Your Next Project

– High-Quality Lenses

– Dust Extraction System

– Precision (Tool)

Related Articles

Best Woodworking Tools for DIY Projects

How to Maintain Your Wood Lathe

Top 5 CNC Machines for Woodworking Enthusiasts

How to Choose the Best Fiber Laser Engraver for Wood

When selecting a fiber laser engraver for wood projects, it’s essential to consider several factors to ensure you get the best results. Here’s a concise guide based on the detailed information provided:

-

Power Output: Opt for a machine with between 50W to 100W. Higher wattage is better for thicker or darker woods.

-

Engraving Area: Choose an area that suits your project size, such as 20×30 cm for smaller projects or up to 40×60 cm for larger ones.

-

Resolution: At least 1200 DPI is recommended for sharp and detailed engravings.

-

Cooling System: Decide between water-cooled (better for continuous use) or air-cooled systems based on your usage frequency.

-

Software Compatibility: Ensure the engraver supports popular CAD software and has user-friendly controls.

-

Wood Selection: Use softwoods like basswood for beginners or hardwoods like oak for decorative projects. Prepare the wood by cleaning and sanding it to a smooth finish.

-

Maintenance: Regularly clean the lens, check the cooling system, and calibrate your machine to maintain performance.

FAQ Summary

- Fiber vs CO2 Lasers: Fiber lasers are more efficient and suitable for metals, while CO2 lasers are better for organic materials like wood.

- Wood Types: Basswood is ideal for beginners; oak offers natural grain patterns.

- Software Needs: Use CorelDRAW or Adobe Illustrator, with some machines providing proprietary software.

- Power Requirements: 50W to 80W typically suffices for wood projects.

- Safety: Follow guidelines like wearing protective eyewear and ensuring ventilation.

Conclusion

Selecting the best fiber laser engraver involves balancing power, resolution, cooling, and software compatibility. With proper maintenance and technique, you can achieve stunning engravings on various woods.

Katarina Cho (verified owner) –

The laser engraver stands out for its versatility across materials. It excels with wood, offering clean engravings though slightly slower on dense types. Acrylic benefits from precise cuts and smooth edges; a minor suggestion is adding a cooling system to prevent warping. Leather shows fine details without scorching. Ideal for small spaces, it’s perfect for creating custom signs, jewelry tags, or artistic pieces, making it suitable for both business and creative applications. Balancing speed and precision, this engraver effectively handles diverse projects in various settings.

Daisuke Han (verified owner) –

This laser engraver excels in performance across various materials. For wood, it delivers crisp engravings with minimal burn marks, ideal for custom furniture labels. Acrylic work is equally impressive, producing vibrant results quickly. While precision is high, thicker leather requires multiple passes. The 100W power and 1200 DPI resolution ensure sharp details, though the smaller workspace limits larger projects. Setup was straightforward, and the intuitive software streamlines project management. At $799, it offers excellent value for hobbyists and small businesses, though frequent maintenance would enhance longevity.

Lisa Williams (verified owner) –

The laser engraver excels in precision across various materials like wood, acrylic, and leather, delivering sharp engravings consistently. Setup was straightforward, and the intuitive software interface made it easy to navigate even for newcomers. Features such as auto-focus enhance accuracy, though additional customization options would benefit artists. Cost-effective with durable results, it offers good ROI for small businesses and hobbyists alike.

Luigi Rossi (verified owner) –

The laser engraver excels across various materials, delivering crisp results on wood, acrylic, and leather. It handles intricate designs with precision, particularly impressive on acrylic where details remain sharp. While processing thicker leather is slightly slower, it maintains consistency. The setup was straightforward, and the software’s intuitive interface includes features like real-time previews and batch processing, enhancing efficiency. Autofocus ensures accurate engraving without manual adjustments. A minor suggestion would be to expand template options for varied projects, though this does not detract from its overall effectiveness.

Viktor Zhang (verified owner) –

**Laser Engraver Review: Craft Store Owner’s Perspective**

**1. Specific Project Experience – Custom Wooden Signs**

– **Project Overview:** I utilized the laser engraver for custom wooden signs, focusing on both functionality and aesthetics.

– **Materials Used:** Birch plywood was chosen for its smooth surface, ideal for detailed engravings.

– **Challenges Faced:** Achieving consistent depth across curved surfaces was challenging due to varying material density.

– **Solutions Implemented:** By adjusting the laser’s power settings and using multiple passes at lower intensity, we maintained even engraving without burning through the wood.

**2. Technical Performance**

– **Power and Precision:** The laser engraver operates at 40W, providing sufficient power for detailed engravings on materials like wood up to 1″ thick. It achieves precise details down to a point size of 0.5mm.

– **Software Experience:** The accompanying software is intuitive with a user-friendly interface, allowing staff without advanced technical skills to design and prepare files efficiently.

– **Special Features:** Auto-focus ensures accurate engraving on varying surfaces, while vector cutting capabilities enable clean cuts for intricate designs.

**3. Business/Creative Impact**

– **Workflow Improvement:** The laser engraver has significantly reduced setup time compared to traditional methods, allowing us to handle more projects within tight deadlines.

– **Customer Feedback:** Customers have praised the intricate details and professional finish of our custom signs, leading to increased satisfaction and repeat business.

– **Return on Investment (ROI):** The initial investment was offset by reduced material waste and faster project turnaround times. Higher pricing for custom items has also contributed positively to ROI.

**4. Comparison & Value**

– **Comparison with Previous Tools:** Transitioning from manual engraving tools and CNC machines, the laser engraver offers superior speed and precision. It handles complex designs effortlessly, which was time-consuming before.

– **Cost-Effectiveness:** While the upfront cost is notable, ongoing savings from efficient material use and reduced labor costs make it a worthwhile investment.

– **Time Savings:** Projects that previously took hours to complete now take minutes, freeing up staff for other tasks and enhancing overall productivity.

In summary, integrating the laser engraver into my craft store has elevated our craftsmanship, streamlined operations, and bolstered customer satisfaction. It’s a valuable tool that continues to provide excellent ROI through efficient production and creative possibilities.

Heinrich Li (verified owner) –

This laser engraver transformed creating custom wooden name tags into an effortless process. The precision is impeccable, and the setup was so intuitive that even my kids could pitch in! Perfect for intricate designs.

Joseph Lee –

★★★★★ Exceptional Laser Engraver! The engraving quality and precision are flawless. The machine and software are user-friendly. Fast engraving speed boosts productivity. Solid build, highly reliable.