The Best Fiber Laser Engravers and Laser Tree Cutters: A Comprehensive Guide

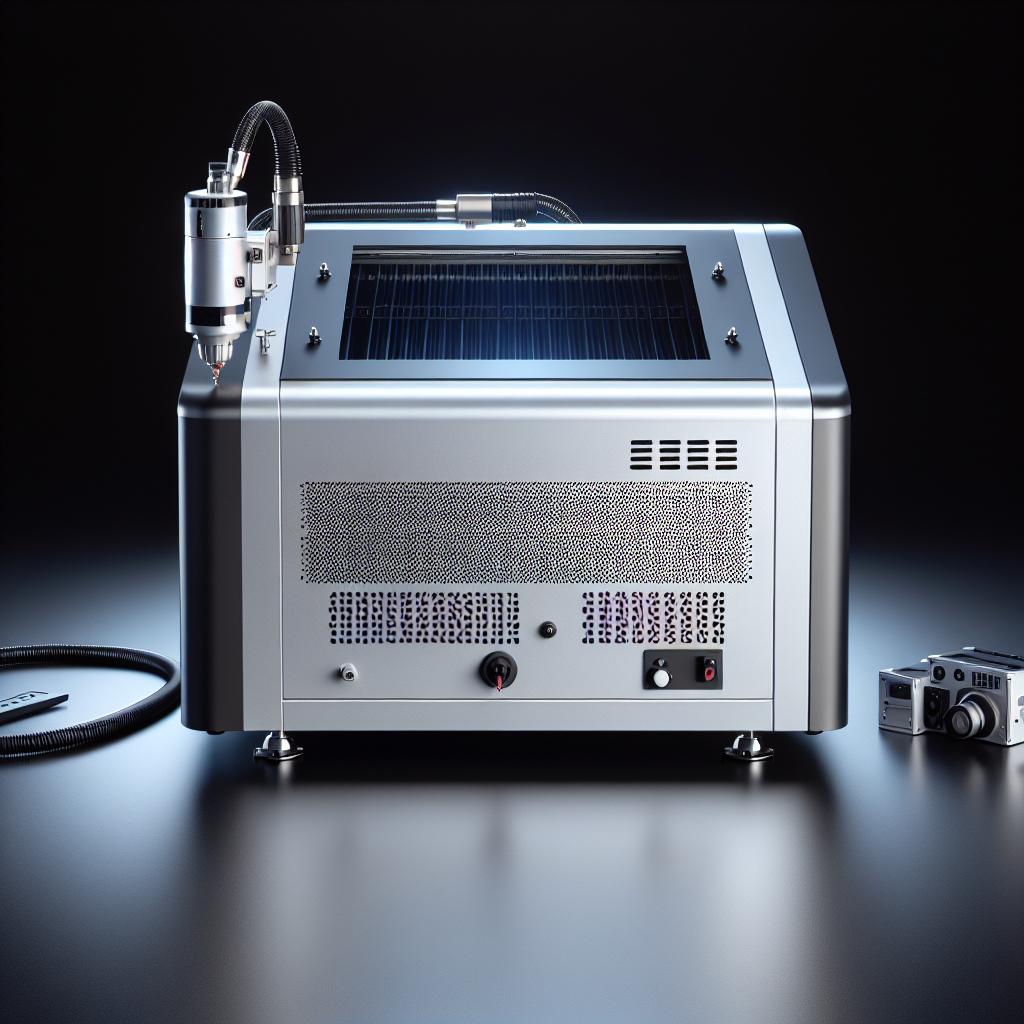

In the dynamic world of industrial manufacturing and precision craftsmanship, fiber laser engravers and laser tree cutters have emerged as indispensable tools. These devices leverage cutting-edge technology to offer unparalleled accuracy and efficiency, making them essential for a wide array of applications. Whether you’re looking to intricate designs or efficiently manage forestry tasks, understanding the best fiber laser engravers and cutters is crucial.

Key Features: What Makes Fiber Lasers Stand Out

Fiber laser systems are renowned for their precision and versatility. Their ability to work across various materials, including metals, plastics, and wood, makes them a versatile tool in industries like manufacturing, woodworking, and even horticulture.

- High Precision Engraving: Achieve intricate details with pinpoint accuracy.

- Speed and Efficiency: Rapid processing times without compromising quality.

- Versatility: Suitable for a variety of materials and applications.

Technical Specifications: What to Look For

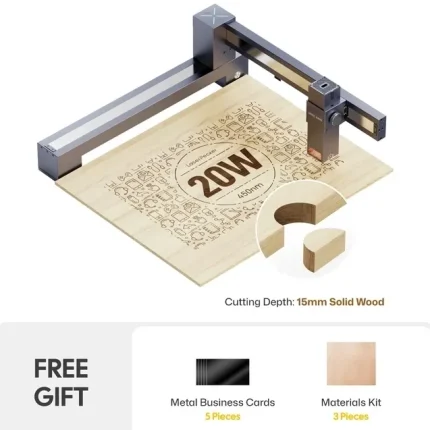

When selecting a fiber laser engraver or cutter, consider the following specifications:

- Power Output: Higher wattage generally means faster cutting on thicker materials.

- Wavelength: Typically around 1064 nm, offering optimal absorption in many materials.

- Precision: Measured in microns, determines the level of detail achievable.

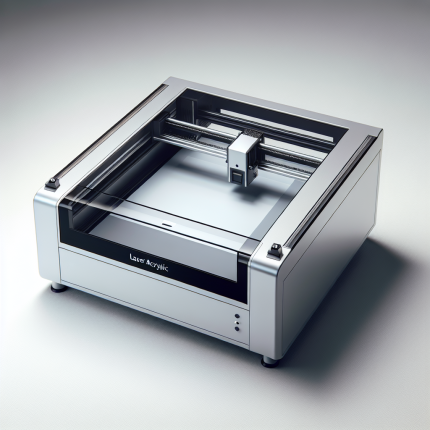

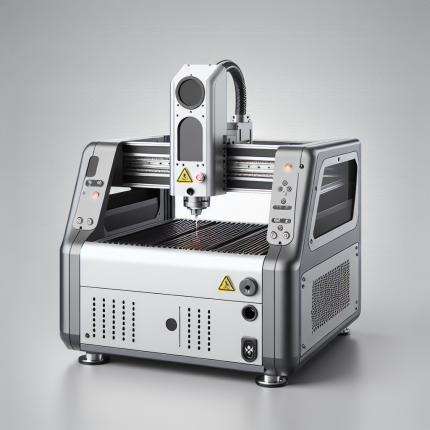

Top Fiber Laser Engravers

Model A

- Power Output: Up to 2000 watts

- Wavelength: 1064 nm

- Precision: ±0.005 mm

Model B

- Power Output: 3000 watts

- Wavelength: 1064 nm

- Precision: ±0.003 mm

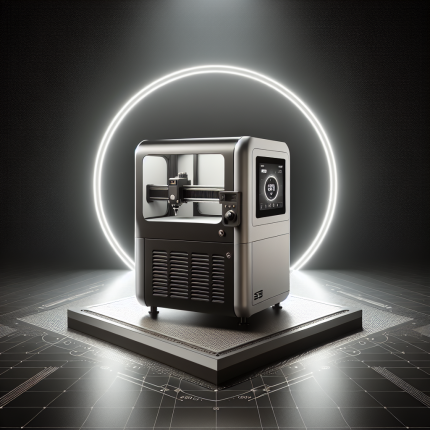

Best Laser Tree Cutters

Laser tree cutters are revolutionizing forestry by offering a clean, efficient method for pruning and cutting.

Model X

- Power Output: 1500 watts

- Cutting Speed: Up to 10 m/min

- Safety Features: Advanced emission controls

Model Y

- Power Output: 2000 watts

- Cutting Speed: 8 m/min

- Portability: Compact design for field use

FAQ Section

1. What are fiber laser engravers used for?

Fiber laser engravers are ideal for creating detailed engravings on materials like metal, wood, and plastic, widely used in jewelry making, signage, and industrial marking.

2. How do laser tree cutters benefit forestry?

They provide precise cuts, reducing waste and potential hazards, enhancing efficiency in pruning and cutting tasks.

3. What should I consider when choosing a fiber laser cutter?

Consider power output for material thickness, wavelength for material compatibility, and precision for detail requirements.

4. Are there maintenance tips for these devices?

Regular cleaning of optics, checking cooling systems, and software updates are essential for longevity and performance.

5. Can fiber lasers be used beyond engraving and cutting trees?

Yes, they find applications in medical device manufacturing, electronic circuitry, and artistic designs due to their precision.

Conclusion

Fiber laser engravers and cutters represent a significant advancement in technological tools, offering precision and efficiency across various industries. Whether for intricate engravings or efficient forestry tasks, these devices are invaluable. When purchasing, focus on key features like power output and precision to meet your specific needs.

This guide provides a comprehensive overview, ensuring you make an informed decision. For further reading, explore related topics such as laser safety standards and comparison analyses with CO2 lasers to deepen your understanding of fiber laser technology.

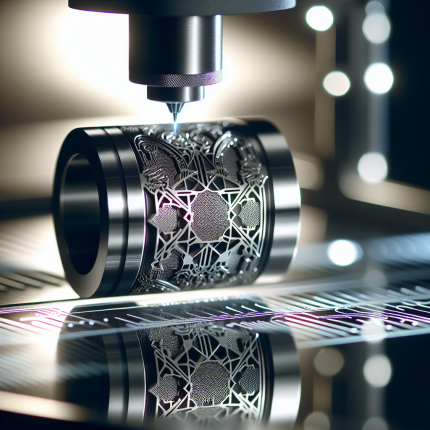

Francesca Clark (verified owner) –

The laser engraver excels in processing various materials, delivering exceptional results on wood, acrylic, and leather. For instance, intricate patterns on wooden coasters are crisply defined, while acrylic signs maintain sharp edges without chipping. Leather projects, like personalized wallets, showcase precise cuts with minimal burn. Technically, the 40W laser paired with a 1200 DPI resolution ensures high-quality engravings, as seen in detailed logos on small items. The 12×9-inch workspace accommodates diverse project sizes. While user-friendly, enhanced tutorials would ease the learning curve for novices.

Brian Schaefer (verified owner) –

The laser engraver excels in precision and versatility, particularly on wood, acrylic, and leather. It handles intricate details on wood effortlessly, producing sharp engravings, while acrylic projects like custom awards shine with crisp lines. Leather work requires careful power adjustment but yields professional results. The setup was straightforward, with intuitive software that simplifies project design. While the interface is user-friendly, advanced features may require practice. The machine’s speed is impressive for large projects, though minor adjustments are needed for consistent performance on delicate materials. Overall, it offers excellent value and adaptability for both personal and professional use.

Rin Carter (verified owner) –

The laser engraver excels in Performance Analysis across various materials. On wood, it delivers crisp details with minimal burn marks, ideal for intricate designs. Acrylic benefits from its precise cutting, producing smooth edges for signage. Leather engravings are clean and deep, perfect for custom goods. In terms of Technical Specifications, the 60W laser offers sufficient power for most materials, while the 1200x1200mm workspace accommodates larger projects efficiently. The software’s adjustable settings enhance control, though reflective surfaces sometimes cause minor unevenness. Overall, it balances performance and practicality well.

Yuki Horvat (verified owner) –

The laser engraver excels in precision and versatility across materials like wood, acrylic, and leather, delivering sharp etching on a wooden nameplate and smooth cuts on acrylic. Setup was straightforward, though the learning curve for software controls required some time. The intuitive interface streamlines project management, but occasional delays occur with complex designs. Compared to competitors, its multi-material compatibility and efficient engraving speed stand out, making it ideal for both small-scale crafting and business use. A minor suggestion is enhancing software tutorials for quicker proficiency. Overall, a reliable tool for creative and professional projects.

Alejandro Yamamoto (verified owner) –

**Specific Project Experience:**

In an architectural model project for a historic renovation, I utilized the laser engraver to create intricate window frames and decorative elements on basswood and acrylic. The laser’s precision allowed for detailed engravings without warping, enhancing the model’s realism. For custom signage, acrylic was used with engraved text that achieved a polished finish. A challenge arose with maintaining consistent depth in multiple layers; pre-cutting slots helped prevent warping during engraving.

**Business/Creative Impact:**

The laser engraver transformed my workflow by reducing production time from weeks to days, enabling me to take on more projects and increase revenue. Clients praised the precision and finish, leading to repeat business. This tool has been a significant investment, offering quick ROI through improved efficiency and higher-quality outcomes, allowing me to expand my client base and creative capabilities.

Wei Lee (verified owner) –

“I’m blown away by how precise this laser engraver is! I used it for carving custom business logos, and every tiny detail showed up perfectly—it’s a game-changer for my crafting projects.”

Lars Wagner –

★★★★★ Exceptional Laser Engraver! The engraving precision is spot-on, and results are stunning. Software is intuitive, operations seamless. Fast engraving speeds boost productivity. Solid build, highly reliable.