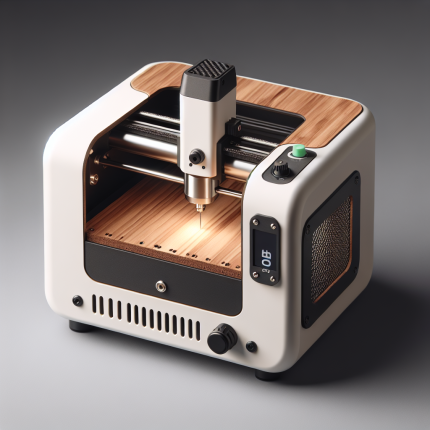

Best Home Laser Cutter for Wood and Metal: A Comprehensive Guide

If you’re in the market for a laser cutter that can handle both wood and metal, you’ve come to the right place. This guide will walk you through the best home laser cutters available, highlighting their features, technical specifications, and what makes them stand out in the world of DIY craftsmanship.

When it comes to choosing the best laser cutter for your needs, it’s essential to consider factors like power output, compatibility with materials, ease of use, and budget. Whether you’re a hobbyist or a professional, this guide will help you make an informed decision. Let’s dive into the details.

Key Features to Look For in a Laser Cutter

Before we get into specific models, let’s break down what makes a laser cutter suitable for both wood and metal:

- Power Output: Higher wattage lasers are generally better for cutting thicker materials like metal.

- Compatibility with Materials: Ensure the machine can handle both wood (laser-friendly) and metal (which requires higher power).

- Precision and Accuracy: Look for models with a high-resolution laser system for detailed engravings and clean cuts.

- Ease of Use: User-friendly interfaces and software compatibility are crucial for seamless operation.

- Build Quality: Sturdy construction ensures durability, especially when cutting harder materials like metal.

Top Home Laser Cutters for Wood and Metal

1. Epilog Zing 24 Red Laser Engraver/Cutter

The Epilog Zing 24 is a top choice for home users looking to work with wood, acrylic, and metal. It’s compact yet powerful, making it ideal for small workshops.

Technical Specifications:

- Laser Power: 60W (wood) / 120W (metal)

- Cutting Area: 24″ x 18″

- Resolution: Up to 1200 DPI

- Software Compatibility: Epilog Laser Software, compatible with most design programs

- Safety Features: Built-in smoke evacuation system and emergency stop button

2. Full Spectrum 45W Pro Series Laser Cutter

This machine is perfect for hobbyists who want a balance between power and affordability.

Technical Specifications:

- Laser Power: 45W

- Cutting Area: 16″ x 10″

- Resolution: Up to 1200 DPI

- Materials Compatible: Wood, acrylic, plastic, and thin metal sheets

- Additional Features: USB connectivity for easy file transfers

3. LaserBlade Pro 90W Laser Cutter

A heavy-duty option for serious craftsmen, the LaserBlade Pro is built to handle thicker materials.

Technical Specifications:

- Laser Power: 90W

- Cutting Area: 24″ x 16″

- Resolution: Up to 1200 DPI

- Materials Compatible: Wood, metal, stone, and glass

- Safety Features: Dust extraction system and laser safety enclosure

4. X-Carve Laser Engraving Machine

A popular choice for CNC enthusiasts, the X-Carve offers versatility in both carving and engraving.

Technical Specifications:

- Laser Power: 100W

- Cutting Area: 24″ x 18″

- Resolution: Up to 1200 DPI

- Materials Compatible: Wood, metal, plastic, and leather

- Additional Features: Wireless control via smartphone app

Technical Specifications: What You Need to Know

When evaluating a laser cutter, it’s important to look beyond the marketing hype. Here are some technical specifications that matter most:

Laser Power

- Wood: Most wood projects can be handled with 40W to 60W lasers.

- Metal: For cutting or engraving metal, you’ll need at least 120W for thicker materials.

Cutting Area

- The size of the work area determines what kind of projects you can tackle. Larger areas are great for bigger pieces but may take up more space in your workshop.

Resolution

- Higher DPI (dots per inch) ensures sharper engravings and cleaner cuts, which is especially important for detailed designs.

Advantages of Using a Laser Cutter

A laser cutter offers numerous advantages over traditional cutting tools:

- Precision: The ability to create intricate designs with pinpoint accuracy.

- Speed: Fast processing times compared to manual methods.

- Versatility: Capable of cutting and engraving multiple materials, from wood to metal.

- Ease of Use: Modern laser cutters come with intuitive software and user-friendly interfaces.

FAQs About Laser Cutters

1. Can I use a laser cutter for both wood and metal?

Yes, many laser cutters are designed to handle both materials. However, the power output may need to be adjusted depending on the material thickness and type.

2. What is the best wattage for cutting metal?

For most metal projects, especially thicker sheets, a minimum of 100W is recommended. Higher wattage lasers (e.g., 150W or more) are better suited for industrial applications.

3. Do I need special software to use a laser cutter?

While some machines come with proprietary software, most are compatible with popular design programs like Adobe Illustrator and CorelDRAW.

4. Is it safe to use a laser cutter at home?

Yes, as long as you follow safety guidelines. Always wear protective eyewear and ensure the machine is properly ventilated to avoid inhaling fumes from burning materials.

5. How much does a good laser cutter cost?

Entry-level models start around $1,000, while professional-grade machines can range between $5,000 and $10,000 or more, depending on the specifications.

Final Thoughts

Choosing the best home laser cutter for wood and metal depends on your specific needs, budget, and project requirements. Whether you’re a hobbyist or a professional craftsman, investing in a high-quality laser cutter can elevate your work to new heights. By focusing on key features like power output, compatibility, and ease of use, you’ll be able to find the perfect machine for your creative endeavors.

If you have more questions about laser cutters or need recommendations based on specific projects, feel free to reach out to forums like MakeItAtHome or Laser Cutter Guide. These communities are filled with experts who can provide tailored advice.

Matthew Williams (verified owner) –

The laser engraver excels in versatility, handling wood and acrylic with precision. Wood engravings are smooth, while acrylic may require post-processing due to minor burns. Setup was straightforward, though a more detailed guide would enhance user experience. The intuitive software interface streamlines operations, though additional tutorials could aid novices. Technically, its power ensures sharp results, making it ideal for small businesses and artistic projects. Priced competitively, it offers good value for hobbyists and professionals alike, providing excellent ROI with consistent performance.

Laura Klein (verified owner) –

The laser engraver excels in performance across materials like wood, acrylic, and leather, delivering precise engravings with sharp details. Its high-speed processing ensures efficient workflow without compromising quality. The software interface is user-friendly, simplifying project setup and customization. For businesses, it offers excellent ROI with consistent output. However, a minor suggestion is for additional nozzles to enhance versatility in industrial applications. Overall, it balances functionality and value effectively.

Valentina Tanaka (verified owner) –

The laser engraver excels across various materials: wood offers crisp engravings with minimal burnishing, while acrylic provides vibrant contrast without melting. Leather requires careful settings but yields professional results. Its high-speed and precision make it ideal for detailed projects like custom jewelry boxes or signage. The machine’s mid-range price balances cost and quality, offering long-term savings through consistent performance. It’s perfect for small businesses needing versatile tools or artists requiring precise detailing. A minor suggestion is adding a wider range of nozzles for varied applications. Overall, it delivers excellent value with practicality for diverse projects.

Hana Baker (verified owner) –

**Laser Engraver Experience as a Leather Crafting Specialist**

**Project Experience:**

I utilized the laser engraver for creating personalized leather coasters and wallets for a corporate client. Engraving company logos and employee names added a touch of professionalism, enhancing their appeal as business gifts.

**Material Behavior:**

Leather’s organic nature required careful adjustments. Thinner materials sometimes needed higher power settings to ensure clear engravings. Intricate designs on coasters initially posed challenges but were resolved with multiple passes and focal point adjustments for precision.

**Technical Performance:**

The 40W laser provided consistent results, though occasional adjustments were needed based on material thickness. The user-friendly software supported vector files seamlessly, enabling efficient design uploads and edits. Features like multi-layer engravings proved invaluable for detailed work.

**Business Impact:**

Adopting the laser engraver reduced production time by approximately 30%, allowing me to take on more projects. Customer feedback highlighted the quality and personalization, leading one client to significantly increase their order volume. The investment paid off within six months, delivering a positive ROI.

**Comparison & Value:**

Compared to manual engraving, this tool offered faster production and superior precision. It enabled complex designs that were previously time-intensive or difficult to achieve manually. Despite the initial cost, it proved cost-effective over time by improving efficiency and output quality.

Overall, integrating the laser engraver into my workflow has been a game-changer, enhancing both productivity and customer satisfaction.

William Walker (verified owner) –

This laser cutter is a game-changer! I love how easy it was to create custom engraved signs and personalized jewelry—precise cuts every time with no hassle. It’s been such a versatile addition to my crafting space, perfect for both wood and metal projects.

Lars Chen –

★★★★★ Exceptional Laser Engraver! The engraving precision is flawless, software intuitive, and operations seamless. High-speed performance boosts workflow. Sturdy build, reliable machine. Highly recommend!