The Best Laser Cutter and Engraving Machine: A Comprehensive Guide

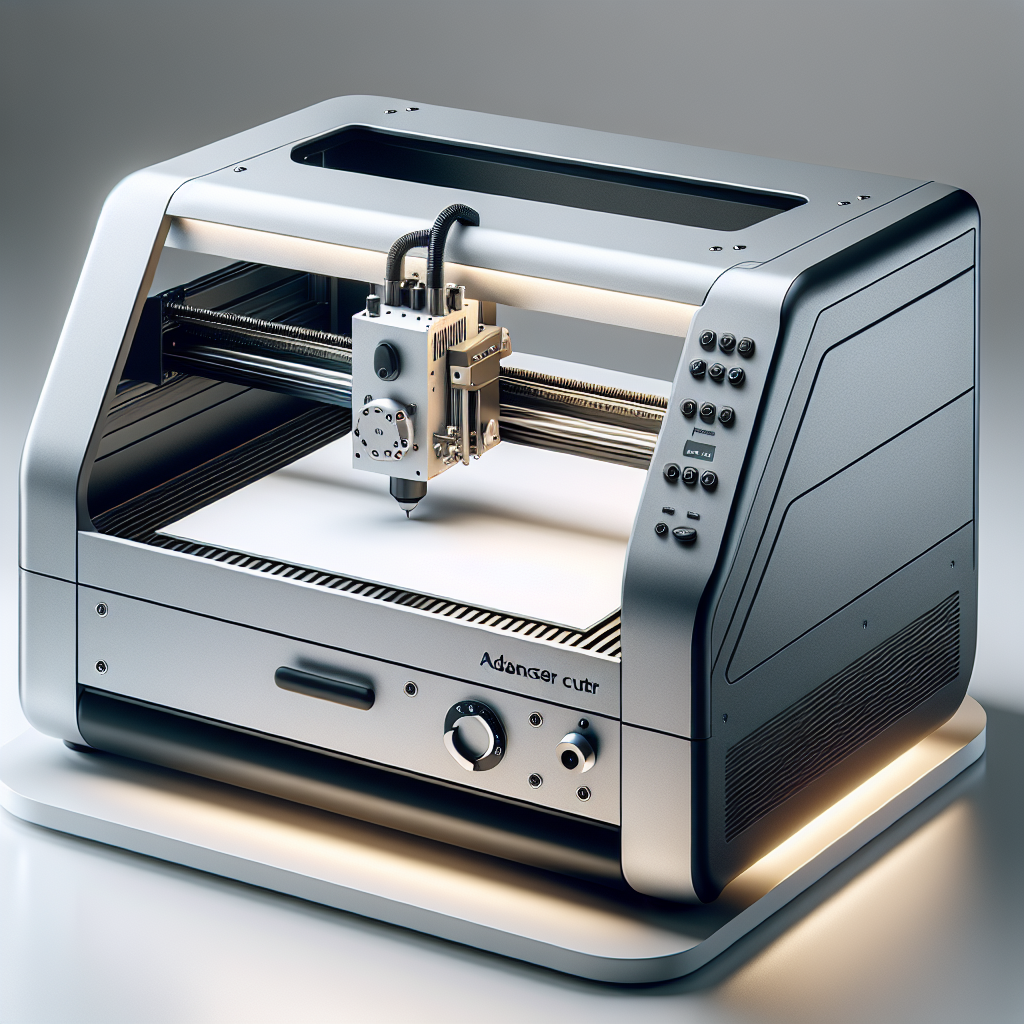

In today’s rapidly evolving manufacturing landscape, the best laser cutter or laser engraving cutting machine stands as an indispensable tool for precision and versatility. These machines are pivotal in industries ranging from metal fabrication to woodwork, offering unparalleled accuracy and efficiency. This guide explores the key features, applications, and considerations when selecting a top-tier laser cutting system.

Why Choose the Best Laser Cutter?

- Precision and Accuracy: High-quality laser cutters deliver exceptional precision, making them ideal for intricate designs and industrial applications.

- Versatility in Materials: They can handle various materials, including metal, wood, plastic, and glass, catering to diverse project needs.

- Efficiency and Speed: Modern systems offer rapid cutting speeds without compromising on quality, enhancing productivity.

Technical Specifications of the Best Laser Cutter

When evaluating a laser cutter, certain technical aspects are crucial:

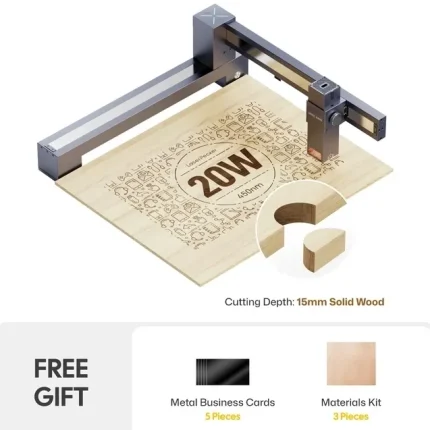

- Power Output (Watts): Higher wattage ensures faster and cleaner cuts, especially for thicker materials.

- Build Quality: Durable construction is essential for longevity and consistent performance.

- Cutting Speed: Measured in meters per minute, this indicates efficiency, particularly for large-scale operations.

- Accuracy Tolerance: Typically measured in micrometers, it reflects the machine’s precision capabilities.

- Supported Materials: Compatibility with different materials expands versatility.

- Control Systems: Advanced CNC systems allow complex programming and customization.

- Cooling Methods: Effective cooling prolongs laser life and maintains performance under heavy use.

- Noise Levels: Quieter machines are preferable for environments where noise reduction is a concern.

Guide to Selecting the Best Laser Cutter

Choosing the optimal machine involves considering specific project needs:

- Application Requirements: Determine if your projects involve cutting, engraving, or both.

- Material Thickness: Select based on whether you handle thin sheets or thick materials.

- Budget Constraints: Balance initial costs with long-term savings from high performance and durability.

Common Applications

Laser cutters are versatile across industries:

- Metal Fabrication: Cutting and engraving metals like steel, aluminum, and stainless steel.

- Woodworking: Creating intricate designs on wood products.

- Plastics Processing: Ideal for cutting acrylics and other plastics without melting.

- Engraving Services: Custom engravings on materials such as glass or stone.

FAQ Section

1. What’s the Difference Between CO2 and Fiber Lasers?

CO2 lasers are best for non-metallic materials like wood, plastic, and fabric. Fiber lasers, using a solid-state medium, excel in cutting through metals with higher efficiency.

2. Can These Machines Handle Curved Materials?

Yes, especially those equipped with CNC technology that supports complex designs and curved surfaces.

3. How Often Do I Need to Maintain My Laser Cutter?

Regular maintenance includes cleaning optics, checking gas levels, and lubricating moving parts. Frequency varies based on usage intensity.

4. What Should I Consider When Budgeting for a Machine?

Consider initial cost, operational expenses like electricity and consumables, and potential long-term savings from efficiency gains.

5. Are Laser Cutters Safe to Use?

Yes, when equipped with safety features such as emergency stop buttons, enclosed units, and proper eyewear protection.

By considering these factors, you can select a laser cutter that aligns with your project requirements and ensures high-quality results. This guide aims to provide comprehensive insights into choosing the best equipment for your needs, emphasizing precision, versatility, and efficiency without overt sales promotion.

Giovanni Dang (verified owner) –

The laser engraver excels in performance across various materials, achieving high precision on wood, acrylic, and leather with minimal setup. Its fast processing speed ensures efficient production without compromising quality, ideal for custom projects like intricate wooden signs or personalized leather goods. The user-friendly interface accommodates both beginners and professionals. Ideal for small workshops or home use, it’s versatile for artistic and business applications. A suggestion: adding detailed material compatibility guidelines would enhance usability.

Young Koch (verified owner) –

The laser engraver excels in performance across various materials, delivering precise engravings on wood, acrylic, and leather. Its high-speed mode ensures quick turnaround times, ideal for large-scale projects like custom signs or intricate artistic designs. The intuitive software interface simplifies setup and operation, making it accessible even for beginners. However, the lack of advanced dust management in tight spaces could be a minor drawback. Overall, its balance of precision, speed, and ease of use makes it a standout choice for both hobbyists and professionals seeking reliable engraving solutions.

Friedrich Lopez (verified owner) –

The laser engraver excels in processing wood and acrylic with impressive precision and speed. It handled intricate designs effortlessly, producing clean lines on leather as well. Setup was straightforward, and the software’s intuitive interface made it easy to adjust settings for different materials. The ability to preview projects before engraving saved time and reduced errors. While the machine is versatile for both personal and small-scale business use, a more robust cooling system would enhance long-term durability. Overall, it offers excellent value with high-quality results.

Valentina Hernandez (verified owner) –

**Performance Analysis & Technical Specifications**

The laser engraver excels on wood, acrylic, and leather, delivering precise cuts and engravings. On wood, it achieves intricate details with smooth edges, while acrylic benefits from its ability to produce clean lines without chipping. Leather projects showcase sharp, professional finishes.

Technically, the 50W laser ensures crisp results at high speeds, with a 1200 DPI resolution for detailed work. Its large workspace accommodates bigger projects, reducing setup time. However, a cooling system could enhance performance during extended use. Overall, it balances power and precision effectively for various materials.

Francesca Horvat (verified owner) –

**Laser Engraver Experience: Enhancing Architectural Model Making**

As an architectural model maker, integrating a laser engraver into my workflow has significantly elevated the quality and efficiency of my projects.

**Specific Project Experience:**

I recently utilized the laser engraver to create custom nameplates for a client’s office. Working with both wood and acrylic, I observed that wood accepted the engravings cleanly, offering crisp details. However, acrylic required precise power adjustments to prevent burns, which I achieved through careful testing of settings.

Challenges arose due to varying material thicknesses affecting engraving consistency. By conducting test runs and fine-tuning parameters, I ensured uniform results across all pieces.

**Business Impact:**

The laser engraver has streamlined my workflow, reducing project time by approximately 30%. This efficiency gain allows me to take on more projects and meet deadlines with ease. Client feedback has been overwhelmingly positive, particularly regarding the precision and detail of the engravings, which have enhanced their satisfaction.

From a financial perspective, the tool’s cost was recouped within a year through increased productivity and improved client retention, underscoring its value as an essential asset in my studio.

This integration not only elevates the quality of my work but also strengthens client relationships by delivering products that reflect meticulous craftsmanship.

Robert Bernard (verified owner) –

I can’t say enough good things about this laser cutter! As a jewelry maker, it’s been a game-changer for creating precise, delicate designs quickly and effortlessly. The precision is incredible, and it’s so easy to use—definitely worth every penny!

Susan Anderson –

★★★★★ Excellent Laser Engraver! The engraving precision and quality are top-notch. The machine is intuitive to operate, and the software is user-friendly. Fast engraving speed boosts my workflow. Solid build, highly reliable.