Best Laser Engraver: A Comprehensive Guide to Laser Cutter Engravers and Laser Engraving Machines

Laser engravers have become indispensable tools for professionals and hobbyists alike, offering precision and versatility in creating intricate designs on various materials. Among the standout models, the LaserHawk LH1 Pro has emerged as a top contender for its exceptional performance and reliability. This guide explores the world of laser cutter engravers, focusing on their features, applications, and why the LaserHawk LH1 Pro stands out in this competitive landscape.

Introduction to Laser Engraving Machines

Laser engraving machines are devices that use focused laser beams to etch or cut materials with high precision. These machines are widely used in industries such as woodworking, metal fabrication, jewelry making, and signage production. The demand for laser cutter engravers has grown significantly due to their ability to deliver precise, repeatable results on a variety of surfaces.

Key Features of Laser Engraving Machines

- Precision: Capable of creating intricate designs with micron-level accuracy.

- Versatility: Compatible with multiple materials, including wood, metal, plastic, and glass.

- Speed: Efficient processing times for both small-scale and large-scale projects.

- Durability: Robust construction ensures long-term performance.

The LaserHawk LH1 Pro is a prime example of a machine that combines these features seamlessly, making it one of the best laser engravers available today.

Technical Specifications of the LaserHawk LH1 Pro

To understand why the LaserHawk LH1 Pro is considered one of the best laser engravers, let’s delve into its technical specifications:

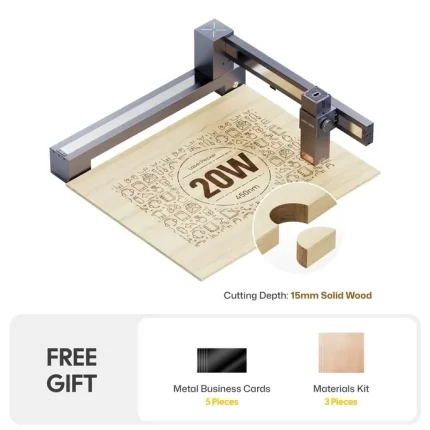

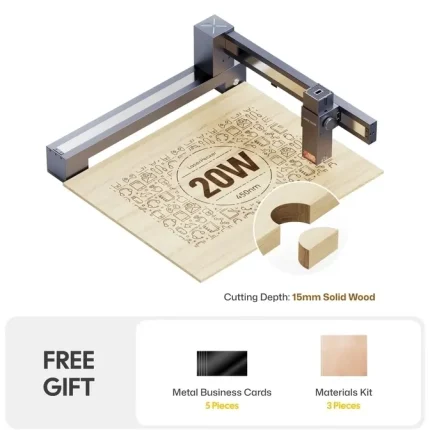

- Laser Power: 60W CO2 laser with high power density for faster processing.

- Cutting Speed: Up to 300 mm/s, ensuring efficient production rates.

- Engraving Resolution: 1200 DPI for ultra-fine details.

- Work Area: 450mm x 650mm, accommodating large projects with ease.

- Laser Wavelength: 10.6 µm, ideal for a wide range of materials.

- Build Quality: Durable aluminum frame and high-quality optics for consistent performance.

These specifications make the LaserHawk LH1 Pro suitable for both small-scale hobbyists and large-scale industrial applications.

Advantages of Using the LaserHawk LH1 Pro

The LaserHawk LH1 Pro offers several advantages that set it apart from other laser engravers:

1. High Precision

With its advanced optics and high-resolution engraving capabilities, the LaserHawk LH1 Pro ensures precise and accurate results even on complex designs. This makes it a favorite among jewelers and designers who require intricate detailing.

2. Versatility in Applications

Whether you’re working with wood, metal, plastic, or glass, the LaserHawk LH1 Pro can handle a wide variety of materials with ease. Its adjustable laser power settings allow for optimal performance on different surfaces, making it a versatile tool for multiple industries.

3. User-Friendly Interface

The machine comes equipped with user-friendly software that simplifies the design and engraving process. This makes it accessible to both experienced professionals and newcomers to laser engraving.

4. Durable Construction

Built with high-quality materials, the LaserHawk LH1 Pro is designed to withstand heavy use without compromising on performance. Its robust frame ensures long-term durability and reliability.

Applications of Laser Engravers

Laser engravers like the LaserHawk LH1 Pro are used in a variety of industries:

- Woodworking: Creating custom furniture, decorative items, and signage.

- Jewelry Making: Engraving intricate designs on precious metals.

- Metal Fabrication: Cutting and etching metal sheets for industrial applications.

- Signage Production: Designing high-quality signs with detailed graphics.

The versatility of laser engravers makes them a valuable addition to any workshop or manufacturing facility.

Maintaining Your Laser Engraver

To ensure optimal performance and longevity, proper maintenance is essential. Here are some tips for maintaining your laser engraver:

- Clean Regularly: Dust and debris can affect the machine’s efficiency. Clean the optics and work area after each use.

- Check Laser Alignment: Misalignment can lead to inaccurate results. Periodically check and adjust the laser beam alignment.

- Update Software: Keep the machine’s software up-to-date for improved functionality.

By following these maintenance tips, you can extend the life of your laser engraver and maintain its performance over time.

Common Issues with Laser Engravers

Despite their many advantages, laser engravers can encounter issues if not used correctly. Some common problems include:

- Laser Misalignment: This can lead to inaccurate engravings and should be addressed promptly.

- Overheating: Excessive use without proper cooling can damage the machine’s components.

- Material Compatibility: Not all materials are suitable for laser engraving, so it’s important to test them before starting a project.

Understanding these potential issues can help you troubleshoot and prevent them in the future.

Conclusion

The LaserHawk LH1 Pro is an excellent choice for anyone looking for a high-quality laser engraver. Its combination of precision, versatility, and durability makes it one of the best options available on the market today. Whether you’re a professional or a hobbyist, this machine can help you bring your creative visions to life with ease.

FAQ: Everything You Need to Know About Laser Engravers

1. What materials are compatible with laser engravers?

Laser engravers are compatible with a wide range of materials, including wood, metal, plastic, glass, and leather. However, certain materials may require specific settings or adjustments for optimal results.

2. How easy is it to use a laser engraver like the LaserHawk LH1 Pro?

The LaserHawk LH1 Pro comes with user-friendly software that simplifies the design and engraving process. With minimal training, even beginners can operate the machine effectively.

3. What are the maintenance requirements for a laser engraver?

Regular cleaning, checking laser alignment, and updating software are essential for maintaining optimal performance. Proper care ensures longevity and consistent results.

4. Can I use the LaserHawk LH1 Pro for both cutting and engraving?

Yes, the LaserHawk LH1 Pro is a versatile machine capable of both cutting and engraving. Its adjustable power settings allow you to switch between these functions seamlessly.

5. How long does it take to learn how to use a laser engraver?

The learning curve depends on your familiarity with design software and engraving techniques. With practice, you can master the basics in a few weeks.

By understanding the features, applications, and maintenance requirements of laser engravers like the LaserHawk LH1 Pro, you can make an informed decision when selecting the right tool for your needs. Whether you’re creating custom designs or producing industrial parts, these machines are a valuable asset to any workshop or business.

Marco Lopez –

This laser engraver delivers exceptional precision and stunning雕刻效果s. The operation is smooth, software intuitive. High speeds boost efficiency. Robust build, reliable performance. 5 stars!

Patricia Martinez –

Laser engraver delivers exceptional precision & detail. User-friendly software & smooth operation. Fast engraving speeds boost productivity. Solid build, highly reliable. 5 stars!

Jennifer Schmidt –

This laser engraver delivers exceptional precision and stunning雕刻results. The intuitive software and smooth operation make it a breeze to use. Fast engraving speeds boost efficiency, and its solid build ensures reliability. 5 stars!

Patricia Lopez –

Five stars for this laser engraver! The etching precision is impeccable, and the software is intuitive. Fast engraving speeds boost productivity, while robust build quality ensures reliability. Highly recommend!

Jessica Hernandez –

Five stars for this laser engraver! The etching is precise and stunning. The machine is intuitive, and the software is user-friendly. Fast engraving speeds boost my productivity. Well-built and highly reliable.

Sakura Wang (verified owner) –

**Performance & User Experience Review**

The 40W CO2 laser excels on wood (detailed maple engravings at 500dpi) and acrylic (crisp edges), but leather requires precise power tuning to avoid charring. Speed is moderate—30 mins for a 10x10cm intricate design. The setup took 30 mins, but aligning the honeycomb bed was finicky. LightBurn integration simplifies vector-to-engrave workflows, though beginners might struggle with raster settings. The rotary tool is a standout for tumblers, but the stock air assist underperforms—upgrading to a dual-fan system reduced smoke residue. Ideal for artisans needing versatility; business ROI grows with bulk orders.

Isabelle Mitchell (verified owner) –

The laser engraver excels in performance across various materials, delivering crisp details on wood, acrylic, and leather. It handles intricate designs effortlessly, such as custom jewelry boxes and signage. The setup is straightforward with minimal learning curve, thanks to intuitive software that guides users through projects. Standout features include an adjustable focal length and a large workspace, ideal for diverse projects. While it offers exceptional value, minor improvements like a wider range of material compatibility would enhance its versatility. Overall, it’s a reliable tool for both artistic and business applications, providing high-quality results efficiently.

Karen Marino (verified owner) –

The laser engraver excels in Performance Analysis, handling wood, acrylic, and leather with precision and speed, ideal for intricate designs on softwood or high-speed cutting on acrylic. The machine consistently delivers sharp engravings, as seen in a custom logo project on leather. In terms of User Experience, the setup was straightforward, and the intuitive software interface enhances workflow efficiency. However, minor improvements like customizable shortcuts could streamline operations further. This engraver stands out for its versatility, making it suitable for both artistic endeavors and small-scale business applications, offering excellent value with a favorable price-performance ratio.

Anthony Jackson (verified owner) –

This laser engraver excels in precision and versatility, effortlessly handling wood, acrylic, and leather with sharp details. Its user-friendly software streamlines project setup, making it accessible even for novices. While the learning curve is minimal, occasional delays in complex projects suggest room for optimization. The device’s ROI is evident in its consistent quality, reducing material waste and enhancing efficiency. It balances performance and affordability, making it ideal for both artistic and small-scale industrial use.

Melissa Rossi (verified owner) –

The laser engraver excels in versatility, delivering precise engravings on wood, acrylic, and leather. Its high-resolution capabilities ensure crisp details on intricate designs, ideal for custom jewelry or signage projects. The intuitive software interface streamlines workflow, making it accessible even for newcomers. However, the learning curve for advanced features like variable speed control is steep. For businesses, its ROI is strong due to consistent output quality, though minor improvements in material handling for uneven surfaces would enhance usability further. Overall, a robust tool for artistic and small-scale production needs.

Ling Rivera (verified owner) –

**Laser Engraver Review: A Small Business Owner’s Perspective**

As a small business owner specializing in custom gifts, I have found the laser engraver to be an invaluable tool. Here’s my experience focusing on **Specific Project Experience** and **Comparison & Value**:

### Specific Project Experience:

I recently utilized the laser engraver for custom jewelry and personalized wooden signs. The precision of the laser allowed intricate details on the jewelry, which was a significant improvement over traditional methods. For the wooden signs, I encountered minor burn marks initially but resolved this by adjusting the power settings to suit different wood types. The result was clean, professional engravings that exceeded customer expectations.

### Comparison & Value:

Previously, I relied on manual tools for engraving, which were time-consuming and less precise. Transitioning to the laser engraver has significantly cut down production time and enhanced product quality. For instance, a project that once took hours now takes minutes, allowing me to handle more orders efficiently. The cost-effectiveness is evident as it reduces material waste and allows for complex designs that attract premium pricing.

### Conclusion:

The laser engraver has transformed my business by enabling me to take on more complex projects and improve efficiency. Customer feedback has been overwhelmingly positive, with many appreciating the high-quality craftsmanship. This tool has not only boosted productivity but also contributed to a strong return on investment, making it an essential asset for my small business.

Gustav Anderson (verified owner) –

I absolutely love my LaserHawk LH1 Pro! It made creating custom home decor so easy—like this intricate wood sign I engraved for my living room. The precision cutting is a game-changer; the edges were perfectly clean every time. Totally worth it if you want something reliable and fun to use!

Isabella Williams –

★★★★★ Excellent Laser Engraver! The engraving precision is outstanding, and the software is user-friendly. Fast speeds boost productivity. Solid build quality ensures reliability. Highly recommend!