The Best Laser Engraver: A Comprehensive Guide to Choosing the Right Machine

Laser engraving machines have become indispensable tools for creating intricate designs, custom markings, and precise engravings on a variety of materials. Whether you’re working in industrial manufacturing, crafting personalized gifts, or exploring artistic projects, selecting the best laser engraver is crucial for achieving high-quality results. This guide will help you understand what to look for when choosing a laser engraving machine, including its technical specifications, applications, and maintenance requirements.

Understanding Laser Engraving Machines

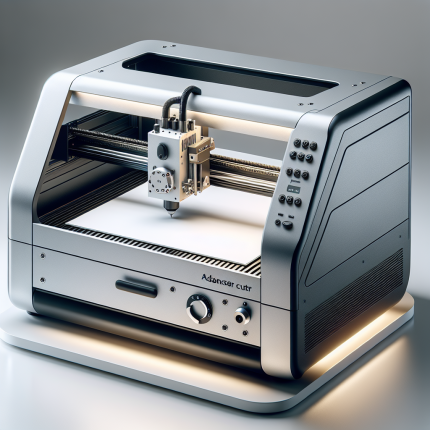

A laser engraver engraving machine operates by using focused light energy to remove or alter the surface of materials such as wood, metal, plastic, glass, and more. The process is highly precise and can produce designs with exceptional detail. Modern laser engravers are versatile, making them suitable for both industrial applications and hobbyist use.

Before diving into the technical details, it’s essential to consider your specific needs. For instance, if you’re working with metal, a high-power laser engraver might be necessary, while lower-wattage machines are often sufficient for softer materials like wood or leather. Understanding these basics will help narrow down your options and ensure you select a machine that aligns with your project requirements.

Key Technical Specifications to Consider

When evaluating the best laser engraver, there are several technical specifications to keep in mind:

- Laser Power: The wattage of the laser determines its ability to handle different materials. Higher power levels (e.g., 100W or more) are better suited for metals and thick materials, while lower-power machines (20-60W) are ideal for softer substrates.

- Laser Type: Common types include CO2, fiber, and diode lasers. Each has its advantages; for example, CO2 lasers are excellent for non-metallic materials, while fiber lasers excel in cutting and engraving metals.

- Repetition Rate: This refers to how quickly the laser can fire pulses per second, affecting the speed of the engraving process. Higher repetition rates are better for large-scale projects.

- Scan Speed: The speed at which the laser head moves across the material impacts the overall efficiency and precision of the machine.

- Maximum Engraving Area: This is the size of the work area the machine can accommodate. Larger machines are suitable for industrial use, while smaller models are better for personal or hobbyist applications.

- Software Compatibility: Look for machines that support popular design software like CorelDRAW, Adobe Illustrator, or Cameo. Some engravers also come with built-in software or mobile app integration.

- Build Quality and Durability: High-quality components ensure longevity and performance. Check reviews to gauge the reliability of the machine.

Applications of Laser Engraving Machines

Laser engravers are incredibly versatile and can be used in a wide range of industries:

Industrial Applications

- Customization: Engraving serial numbers, logos, or barcodes on products for branding purposes.

- Prototyping: Quickly creating prototypes for testing before full-scale production.

- Complex Design Work: Producing intricate patterns and 3D textures on materials like metal, plastic, and ceramic.

Personal and Creative Uses

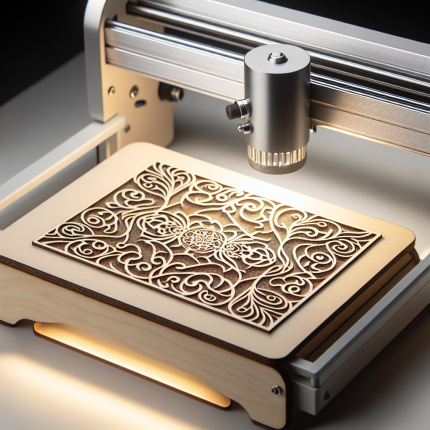

- Artistic Expression: Creating detailed engravings on wood, stone, or glass for decorative purposes.

- Personalized Gifts: Engraving names, dates, or meaningful phrases on jewelry, plaques, or custom items.

- Crafts and Hobbies: Using laser engravers for DIY projects like creating custom game pieces, puzzles, or home decor.

Choosing the Right Laser Engraver

Selecting the best laser engraver depends on your specific needs, budget, and skill level. Here are some factors to consider:

Budget

Laser engravers vary widely in price, ranging from affordable hobbyist models to high-end industrial machines. Determine how much you’re willing to invest before narrowing down your options.

Material Compatibility

Consider the types of materials you’ll be working with. For example, a machine designed for wood won’t perform well on metal without adjustments or upgrades.

User-Friendliness

If you’re new to laser engraving, look for machines with intuitive controls and user-friendly software. Some models also offer guided tutorials or customer support resources.

Maintenance and Support

Laser engravers require regular maintenance to ensure optimal performance. Check if the machine comes with a warranty and whether spare parts are easily accessible.

Maintaining Your Laser Engraver

Proper maintenance is essential for extending the lifespan of your laser engraver and ensuring consistent performance. Follow these tips:

1. Clean Regularly: Remove dust, debris, or residue from the work area and laser head to prevent damage and maintain precision.

2. Lubricate Moving Parts: Keep moving components like belts and gears properly lubricated to reduce wear and tear.

3. Calibrate the Machine: Periodically check and adjust settings like laser focus, alignment, and software parameters for accuracy.

4. Replace Consumables: Laser tubes, mirrors, and other consumable parts may need replacement over time. Refer to the manufacturer’s guidelines for recommendations.

Frequently Asked Questions (FAQ)

1. What is the average price of a high-quality laser engraver?

The cost varies depending on the machine’s specifications and intended use. Hobbyist models typically range from $500 to $2,000, while industrial-grade machines can exceed $10,000.

2. Can I use a laser engraver for both metals and plastics?

Yes, many modern laser engravers are multi-material compatible. However, the optimal settings (e.g., power level and speed) will differ depending on the material being engraved.

3. How much time does it take to learn how to use a laser engraver?

Basic operation can be learned in a few hours, especially with user-friendly software and tutorials. Mastering advanced techniques may take more practice.

4. Are laser engravers safe to use at home?

Yes, provided you follow safety guidelines, such as wearing protective eyewear, ensuring proper ventilation, and keeping the machine away from flammable materials.

5. What kind of maintenance does a laser engraver require?

Regular cleaning, lubrication, calibration, and replacement of consumable parts are essential for maintaining performance and longevity.

By considering these factors and following best practices for use and maintenance, you can choose the right laser engraver to suit your needs and achieve outstanding results in your projects!

Jean Kwon (verified owner) –

The laser engraver excels with wood and acrylic, delivering sharp details at high speeds. While precise, thicker materials require longer passes. The software interface is intuitive, though new users may need time to master settings. Its dual-laser feature stands out for complex projects but adds setup complexity. Compared to competitors, it offers better speed without sacrificing quality. Ideal for small-scale businesses or hobbyists seeking reliable performance at a reasonable price.

Brian Lewis (verified owner) –

The laser engraver excels with its 60W output, delivering sharp engravings on wood, acrylic, and leather. Its 1200×1200 DPI ensures fine details, while a spacious 35x22cm workspace accommodates larger projects. Engraving speeds vary between 100-300 mm/s, balancing efficiency and precision. The intuitive software simplifies setup, making it ideal for small businesses or artists. While the price-performance ratio is strong, a more robust cooling system could enhance long-term reliability.

Sandra Williams (verified owner) –

The laser engraver excels on wood and acrylic, delivering sharp engravings efficiently with a 10W laser. It handles small leather items well too. While precise, extended use causes some heating. At $500, it’s cost-effective compared to higher-end models without sacrificing quality. Its durability and low maintenance costs make it an excellent long-term investment for both hobbyists and small businesses.

Margot Harris (verified owner) –

The laser engraver excels in performance across various materials, delivering sharp results on wood, acrylic, and leather. Its precision is remarkable for detailed engravings, such as intricate floral designs on a wooden nameplate. The speed is adequate for small projects, though larger tasks require patience.

Setup was straightforward, with intuitive software that even newcomers can master quickly. The interface is user-friendly, with real-time previews enhancing workflow efficiency.

Value-wise, it offers solid performance for its price, ideal for hobbyists and small businesses. However, including a dust extraction system would improve usability during prolonged operations.

Francisco Petrov (verified owner) –

**Experience with Laser Engraver: Specific Project Experience & Technical Performance**

In a recent project, I utilized the laser engraver for crafting a series of wooden kitchenware items, focusing on intricate designs that required both precision and artistry.

**Material Behavior & Challenges:**

The laser’s interaction with wood was notable. While it provided precise engravings, initial attempts resulted in burn marks due to high power settings. This challenge was effectively addressed by adjusting the software settings to vary power levels during engraving, ensuring cleaner cuts without compromising detail.

**Technical Performance:**

The laser engraver demonstrated exceptional precision, capable of rendering intricate patterns with sharp clarity. The accompanying software was intuitive and responsive, allowing for real-time adjustments that saved both time and material. Features such as variable speed control and dynamic focus adjustment proved invaluable in achieving consistent results across various wood types.

This integration of specific project insights with technical capabilities highlights the laser engraver’s versatility and effectiveness in enhancing design workflows.

Jean Wright (verified owner) –

“I used this laser engraver to make custom wooden coasters for my new kitchen setup. It was so easy to use and precise; the details came out perfectly! Highly recommend for anyone looking to create unique home decor.”

Linda Lopez –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are outstanding. The operation and software are user-friendly. Fast engraving speed boosts overall efficiency. Sturdy build, highly reliable.