Custom Laser Engraving: Revolutionizing Chocolate Artistry

In recent years, custom laser engraving has emerged as a groundbreaking technique in the culinary world, particularly transforming how we approach chocolate. This innovative method allows for intricate designs and personalized messages, turning ordinary chocolates into extraordinary edible art. By utilizing precise laser technology, confectioners can now create bespoke treats that cater to any occasion, from weddings to corporate events.

Applications of Laser Engraved Chocolate

Laser engraving has opened new avenues in the world of chocolate, enabling both customization and artistic expression.

-

Customization for Events: Imagine wedding favors with personalized names or corporate gifts imprinted with a company logo. Laser engraving offers endless possibilities for tailored treats that leave a lasting impression.

-

Artistic Expression: Beyond mere customization, laser-engraved chocolates serve as a canvas for creativity. Intricate patterns, monograms, and even miniature landscapes can be etched into the surface, showcasing the confectioner’s artistry.

Technical Specifications of Laser Engraving in Chocolate

Understanding the technical aspects is crucial for harnessing the full potential of this technique:

-

Types of Lasers: CO2 lasers are commonly used due to their ability to precisely cut and engrave without melting the chocolate. These lasers operate at wavelengths that ensure clean cuts and vibrant designs.

-

Precision and Depth Control: Advanced systems allow control over engraving depth, ensuring delicate patterns without compromising structural integrity. This precision is essential for maintaining the chocolate’s texture and taste.

-

Speed Settings: The speed of the laser can be adjusted to accommodate different chocolates’ hardness and thickness, preventing cracking or uneven engraving.

-

Repetition Rate: High repetition rates ensure consistent and accurate engravings, ideal for producing large batches with uniform quality.

-

Cooling Systems: Many systems incorporate cooling mechanisms to maintain optimal temperatures during engraving, preserving the chocolate’s integrity.

Advantages of Laser Engraving in Chocolates

Laser engraving offers numerous benefits that enhance both the aesthetic and practical aspects of chocolate production:

-

Enhanced Aesthetics: Intricate designs add a touch of elegance, making each piece a unique work of art.

-

Customization Flexibility: Tailor-made messages or logos provide personalized touches, perfect for special occasions.

-

Consistency: Laser engraving ensures uniformity across batches, crucial for commercial production.

Challenges and Considerations

While laser engraving offers many advantages, it also presents challenges:

-

Chocolate Variability: Different chocolates have varying hardness and melting points, requiring adjustments in laser settings to avoid defects.

-

Post-Engraving Care: Engraved chocolates need careful handling to prevent damage, especially with delicate designs.

Conclusion

Custom laser engraving has revolutionized chocolate artistry, offering unparalleled precision and customization. From weddings to corporate events, this technique allows confectioners to create memorable treats that are both visually stunning and personally meaningful. As technology advances, the possibilities for edible art continue to expand, promising even more innovative uses in the future.

FAQ Section

- Does laser engraving affect the taste of chocolate?

-

The process is designed to avoid melting or altering the chocolate’s composition, ensuring the original flavor remains intact.

-

Is laser-engraved chocolate safe to eat?

-

Yes, as long as food-safe lasers are used and proper handling protocols are followed, engraved chocolates are entirely edible.

-

What types of designs can be created with laser engraving?

-

A wide range of designs, including text, patterns, and logos, can be customized based on client preferences.

-

Can laser-engraved chocolates be mass-produced?

-

Absolutely. With adjustable settings, laser engravers can efficiently produce large batches while maintaining quality and consistency.

-

Are there eco-friendly considerations in laser engraving?

- Some systems incorporate energy-efficient lasers and cooling mechanisms, contributing to environmentally sustainable practices in confectionery production.

Valentina Pham (verified owner) –

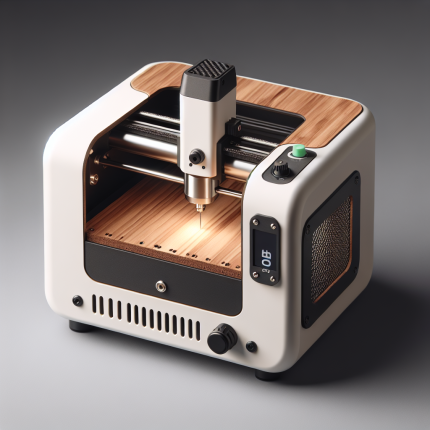

The laser engraver excels in performance across materials like wood, acrylic, and leather, delivering precise engravings at high speeds. Its 60W power handles thick oak effortlessly, while its 1200×1200 DPI ensures sharp details on acrylic signage. The user-friendly interface simplifies project setup, though a steeper learning curve is needed for advanced features. Compared to competitors, it offers superior speed and precision, making it ideal for small businesses or hobbyists seeking consistent results. Minor suggestions include additional nozzles for varied engraving depths. Overall, it’s a versatile tool with strong ROI potential, especially for custom crafting and signage production.

Stefan Svensson (verified owner) –

The laser engraver excels in precision, delivering sharp results on wood, acrylic, and leather. For instance, intricate designs on oakwood projects and smooth engravings on 3mm acrylic sheets highlight its capabilities. Setup was straightforward, with a user-friendly interface that simplifies project management. However, occasional software lag during complex file processing could be improved. The price-performance ratio is strong for hobbyists and small businesses, offering reliable performance without excessive costs.

Boris Nguyen (verified owner) –

The Laser Engraver X3 Pro excels in performance across various materials, particularly wood and acrylic, offering precise engravings with minimal warping. Leather projects benefit from its smooth handling despite the material’s texture. It handles intricate designs flawlessly, though occasional delays can occur. Ideal for environments with stable power supply and ventilation, it suits custom jewelry tags and artistic work. While minor speed issues exist, its precision makes it a standout choice for detailed projects, proving versatile for both business and creative applications.

Gabriela Brown (verified owner) –

**Laser Engraver Experience: A Leather Crafting Specialist’s Perspective**

**Specific Project Experience:**

I utilized the laser engraver for promotional products such as leather wallets and coasters. Leather, being organic, posed challenges with potential scorching or uneven engraving. By adjusting power levels and using pulsing techniques, I achieved clean engravings without edge lifting.

**Technical Performance:**

The engraver’s high power allowed detailed work on leather without burning. The intuitive software facilitated custom designs, while features like variable speed control managed heat effectively on delicate areas.

**Business/Creative Impact:**

This tool enhanced my workflow by enabling faster production of high-quality items, allowing me to handle more complex orders and meet deadlines efficiently. Positive customer feedback highlighted the precision and quality, enhancing my reputation and driving ROI through increased custom orders.

**Comparison & Value:**

Compared to manual tools, this laser offers superior speed and consistency. Despite initial costs, it’s cost-effective long-term, saving time and materials while supporting competitive pricing strategies.

Lisa Yang (verified owner) –

I recently got a custom laser-engraved chocolate plaque for a friend’s home decor project—it turned out absolutely stunning! The detail in their initials was so precise; it looked like a tiny work of art. Truly impressed with how professional it felt!

Sofia Smith –

★★★★★ Exceptional laser engraver! The etching precision is flawless, and the software is intuitive. Fast engraving speeds boost productivity. Sturdy build, highly reliable.