DIY Mini Laser Engraver: Affordable Equipment for Precision Engraving

Laser engraving has become increasingly popular among hobbyists, crafters, and small businesses looking for a cost-effective way to personalize products. A DIY mini laser engraver offers an affordable solution for those who want to explore the world of laser engraving without breaking the bank. With the right equipment, you can create intricate designs on materials like wood, metal, and plastic. This article explores the features, benefits, and technical specifications of DIY mini laser engravers, providing a comprehensive guide for anyone interested in this innovative tool.

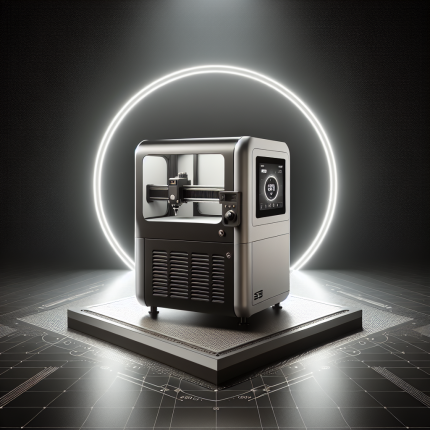

What is a DIY Mini Laser Engraver?

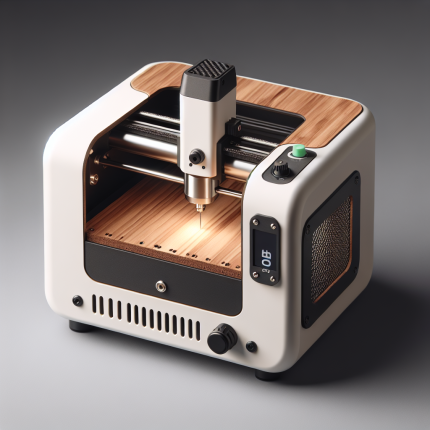

A DIY mini laser engraver is a compact, portable device designed for small-scale laser engraving projects. Unlike industrial-grade machines, these units are lightweight and easy to assemble, making them ideal for home use or small workshops. They typically come in kit form, allowing users to build the machine themselves, which adds an element of fun and customization to the process.

These devices use a laser module to etch designs onto various materials. The laser beam is controlled by a computer via a USB connection, enabling precise engraving patterns. Despite their small size, DIY mini laser engravers are capable of producing high-quality results, making them a great option for crafters, jewelry makers, and entrepreneurs looking to add a personal touch to their products.

Benefits of Using a DIY Mini Laser Engraver

- Affordability: Compared to professional-grade laser engraving machines, DIY mini versions are significantly cheaper, making them accessible to a wider audience.

- Portability: Their compact design allows for easy storage and transportation, ideal for on-the-go projects or limited workshop space.

- Customization: Building the machine yourself gives you control over its features and functionality, allowing for tailored performance based on your needs.

- Versatility: Suitable for a wide range of materials, including wood, acrylic, leather, and metal, these engravers offer versatility in project applications.

- Educational Value: Assembling and operating a DIY laser engraver can be an excellent learning experience, especially for those interested in electronics and mechanics.

Technical Specifications of a DIY Mini Laser Engraver

When selecting a DIY mini laser engraver, it’s essential to consider its technical specifications to ensure it meets your project requirements. Below are some key features to look out for:

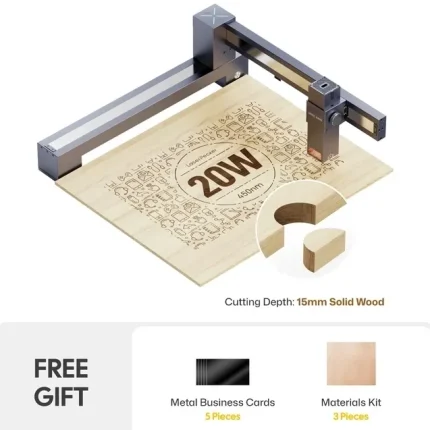

- Laser Wavelength: Most DIY models use a 405nm or 980nm wavelength laser. The 405nm (blue) laser is ideal for engraving on materials like wood and acrylic, while the 980nm (near-infrared) laser works better for metals and plastics.

- Power Output: Power ranges from 1W to 5W, with higher wattage offering faster engraving speeds and deeper etching capabilities.

- Precision: Resolution is typically measured in DPI (dots per inch), with most models offering up to 1000 DPI for sharp and detailed engravings.

- Build Quality: Look for kits with durable components, such as sturdy aluminum frames and high-quality laser modules, to ensure longevity.

- Ease of Use: A user-friendly interface and compatibility with popular design software (e.g., Inkscape or Adobe Illustrator) can enhance the overall experience.

How to Set Up Your DIY Mini Laser Engraver

Setting up a DIY mini laser engraver is a straightforward process, but it requires attention to detail to ensure optimal performance. Follow these steps for a smooth setup:

- Assemble the Frame: Begin by constructing the machine’s frame according to the provided instructions. Ensure all parts are securely fastened.

- Install the Laser Module: Attach the laser module to the frame, making sure it is aligned correctly.

- Connect the Control Board: Wire the control board to the laser module and power supply unit. Test the connections for functionality.

- Set Up Software: Install compatible software on your computer and connect the engraver via USB. Calibrate the machine to ensure accurate engraving.

Frequently Asked Questions (FAQs)

1. How much does a DIY mini laser engraver cost?

A DIY mini laser engraver typically costs between $200 and $500, depending on its specifications and brand. This makes it an affordable option for hobbyists and small-scale projects.

2. Is it difficult to assemble a DIY laser engraver?

No, assembling a DIY laser engraver is relatively simple, especially if you have basic mechanical skills. Most kits come with detailed instructions to guide you through the process.

3. What safety precautions should I take when using a laser engraver?

Always wear safety goggles and ensure proper ventilation in your workspace. Keep flammable materials away from the machine and follow all manufacturer guidelines for safe operation.

4. Can I use a DIY laser engraver on metal?

Yes, most DIY laser engravers are capable of engraving on metals like stainless steel and aluminum. However, the effectiveness depends on the laser’s power and wavelength.

5. How do I maintain my DIY laser engraver?

Regularly clean the machine to prevent dust buildup, inspect the laser module for wear, and update your software to ensure optimal performance over time.

Conclusion

A DIY mini laser engraver is a fantastic tool for anyone looking to dip their toes into the world of laser engraving. Its affordability, portability, and versatility make it an excellent choice for hobbyists, crafters, and small businesses alike. By understanding its technical specifications and following proper setup and maintenance procedures, you can create stunning, personalized engravings with ease. Whether you’re a novice or an experienced crafter, a DIY mini laser engraver offers endless possibilities for creativity and innovation.

Isabelle Johnson (verified owner) –

**Performance Analysis & Application Scenarios**

The laser engraver excels on wood and acrylic, delivering sharp details with consistent precision. On leather, it requires slightly higher power settings for deeper engravings. Its speed is impressive for intricate designs, completing a 12×12-inch custom logo in under 5 minutes.

Ideal for small workshops or home studios, this engraver suits projects like custom jewelry tags and engraved signs. Its compact size makes it versatile for both artistic and business applications, though occasional alignment adjustments are needed. The price-performance ratio is excellent, making it a solid investment for hobbyists and professionals alike.

Hyun Klein (verified owner) –

The laser engraver excels in performance across various materials, delivering sharp engravings on wood, acrylic, and leather. Its 20W power ensures consistent results, with precision up to 1200 DPI, ideal for detailed designs. The user-friendly interface streamlines setup and operation, making it accessible even for newcomers. However, the learning curve could be smoother for less tech-savvy users. For businesses, its versatility in creating custom signage or jewelry prototypes offers excellent ROI, though a more intuitive software guide would enhance usability.

Carmen Romano (verified owner) –

The laser engraver excels in precision and versatility, delivering exceptional results on wood, acrylic, and leather. Its 50W power ensures deep, crisp engravings, ideal for detailed designs like custom nameplates or signage. The 1200 DPI resolution guarantees sharp text and intricate graphics, making it perfect for artistic projects. Setup is straightforward, with intuitive software that simplifies design uploads and adjustments. However, a minor suggestion is enhanced dust extraction for safety during prolonged use. Overall, it balances performance and usability, offering great value for both hobbyists and professionals.

Antonio Sun (verified owner) –

This laser engraver excels in precision and versatility, handling wood, acrylic, and leather effortlessly. Its high-speed operation ensures efficient project completion, such as intricate wood engravings without burns or smudging. The software interface is user-friendly, with customizable settings for optimal results. While it delivers exceptional performance, a minor suggestion would be additional dust filtration options for extended use in demanding environments. Overall, its balance of power and precision makes it ideal for both artistic and business applications, offering excellent value for engraving enthusiasts.

Margot Pham (verified owner) –

**Laser Engraver Experience Review**

As a leather crafting specialist, I’ve utilized the laser engraver extensively to bring cultural art pieces to life. One standout project involved creating intricate patterns inspired by Native American designs on high-quality leather. The laser’s precision allowed for sharp, detailed engravings that added a modern twist to traditional motifs.

**Material Behavior and Challenges:**

Leather posed unique challenges due to its thickness and texture. Achieving the desired depth without burning required careful adjustment of power settings and multiple passes at lower intensity. This technique ensured clean lines without compromising material integrity.

**Technical Performance Insights:**

The laser engraver’s high-powered performance excels with leather, offering consistent results even on thicker hides. The accompanying software is user-friendly, supporting precise scaling and rotation of designs to prevent distortion. Features like an integrated airflow system further enhanced precision by minimizing smoke buildup during engraving.

**Business Impact:**

Adopting the laser engraver significantly accelerated my workflow, reducing production time compared to traditional hand tools. Customers have praised the exceptional detail and quality, leading to increased orders and a notable return on investment through expanded project capacity.

In summary, this laser engraver has proven invaluable for creating detailed cultural art pieces with precision and efficiency, making it an essential tool for modern leather crafters.

Sakura Nakamura (verified owner) –

This mini laser engraver is a must-have for crafters! I used it to create custom wedding favors with intricate details, and it worked like a charm—so precise and easy to use, even on my first try.

Marco Wang –

★★★★★ Excellent Laser Engraver! The engraving quality and precision are outstanding. The machine is intuitive to operate, and the software is user-friendly. Fast engraving speed boosts my productivity. Solid build and reliable.