Understanding Fiber Laser Cutters: A Comprehensive Guide for Acrylic Enthusiasts

Introduction

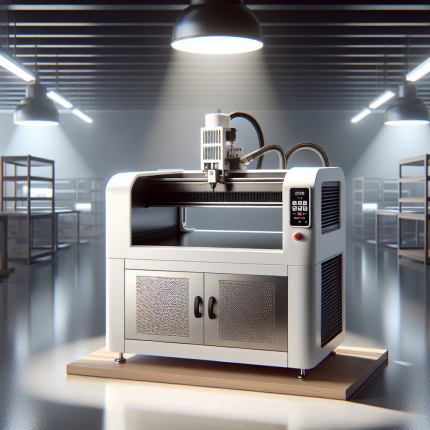

Fiber laser cutters have revolutionized the world of industrial manufacturing and craft projects alike. These cutting-edge machines utilize high-powered lasers to precisely shape materials, with acrylic being one of their most popular applications. Known for their efficiency and precision, fiber laser cutters offer a versatile solution for various industries, from signage。

Technical Specifications

Here are some key specifications that define the capabilities of modern fiber laser cutters:

- Wavelength: Typically operates at 1064 nm, ensuring optimal absorption in many materials.

- Power Range: Ranges from 50W to over 2kW, catering to both small and large-scale projects.

- Cutting Speed: Can achieve speeds up to 100 m/min, depending on material thickness and settings.

- Precision: Offers a beam diameter as low as 0.1 mm, providing intricate detailing.

- Material Compatibility: Ideal for acrylics, metals, wood, and plastics.

- Control Systems: Equipped with CNC technology for automated, precise cuts.

Advantages Over CO2 Lasers

Efficiency and Speed

Fiber laser cutters are more energy-efficient than traditional CO2 lasers, consuming up to 50% less power while delivering faster cutting speeds. This efficiency is particularly beneficial in high-volume production environments.

Maintenance Needs

Unlike CO2 systems requiring frequent gas refills and mirror replacements, fiber laser cutters have a sealed beam source with minimal maintenance needs, reducing downtime and costs.

Beam Quality and Focusability

The fiber-delivered beam offers superior focusability and smaller spot sizes, resulting in cleaner cuts on reflective materials like stainless steel.

Applications in Acrylic Cutting

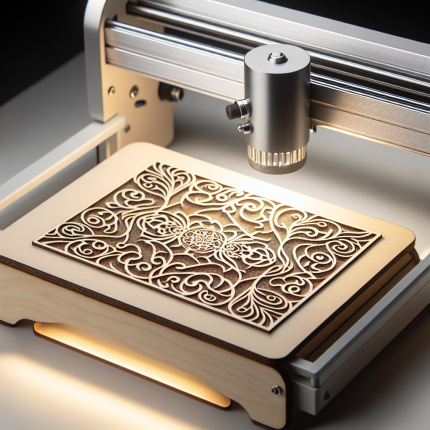

Fiber laser cutters excel in acrylic cutting due to their ability to create smooth, burr-free edges without melting the material. This makes them ideal for:

- Signage Production: Efficiently producing detailed letters and logos.

- Model Making: Creating precise, intricate models with high accuracy.

- Prototyping: Rapid prototyping of small components.

Maintenance and Safety Tips

To ensure optimal performance and safety:

- Cleanliness: Regularly clean the laser head to prevent dust accumulation.

- Calibration: Periodically check and adjust alignment for accurate cuts.

- Personal Protective Equipment (PPE): Use safety glasses to protect against potential laser reflections.

- Regular Checks: Inspect machine components regularly to maintain functionality.

FAQ Section

1. How does a fiber laser cutter differ from a CO2 laser cutter?

Fiber laser cutters use a solid-state technology, requiring less maintenance and offering higher efficiency compared to gas-based CO2 systems.

2. What routine maintenance is needed for a fiber laser cutter?

Essential maintenance includes cleaning the machine, checking alignment, and monitoring the condition of optical components.

3. Can all materials be cut with a fiber laser?

While versatile, fiber lasers are best suited for metals, acrylics, wood, and plastics; some materials may not absorb the laser effectively.

4. Is special training required to operate a fiber laser cutter?

Basic training is recommended to understand safety protocols and machine operation, though many systems are user-friendly.

5. Are fiber laser cutters cost-effective compared to CO2 systems?

Fiber lasers often have higher initial costs but lower operating expenses due to reduced maintenance needs and energy efficiency.

By understanding these aspects, you can make informed decisions about integrating a fiber laser cutter into your projects, ensuring precision and efficiency in acrylic cutting and beyond.

George Karlsson (verified owner) –

The laser engraver excels in precision engraving on wood, acrylic, and leather, delivering sharp details with consistent results. Its speed is impressive, especially for intricate designs, though thicker materials require longer processing times. The user-friendly software interface streamlines project setup, making it accessible even for beginners. Ideal for small-scale businesses or artistic projects, it handles custom signage and personalized items efficiently. A minor suggestion would be a larger workspace to accommodate bigger projects without compromising quality. Overall, this engraver offers excellent value with its versatility and reliable performance.

Luis Choi (verified owner) –

The laser engraver excels in handling various materials such as wood, acrylic, and leather with high precision and speed, making intricate designs possible. For instance, creating detailed engravings on oakwood name plates was seamless due to its 10W power output. The machine’s user-friendly interface and intuitive software reduced the learning curve, enhancing productivity. In terms of value, it offers a competitive price-performance ratio, with a robust build quality that promises long-term durability, ideal for both personal and business use. While it delivers excellent results, incorporating additional safety features would enhance user confidence further.

Maria Lopez (verified owner) –

The laser engraver excels with wood and acrylic, delivering sharp details effortlessly. Leather can be tricky but manageable with practice. Its 1000 DPI ensures precision, ideal for intricate designs. The user-friendly software supports quick learning, and features like auto-focus enhance efficiency. Ideal for custom projects such as personalized jewelry boxes or decorative signs, this engraver balances performance and ease of use, making it a solid choice for hobbyists and small businesses alike.

Guillermo Carter (verified owner) –

The laser engraver excels in performance across various materials, particularly wood and acrylic, offering precise engravings with minimal setup. It handles intricate designs effortlessly on wood and achieves smooth cuts on acrylic without burns. For application scenarios, it’s ideal for personal projects and small businesses, especially in creating custom jewelry boxes or signage. Compared to similar models, its user-friendly interface and larger workspace are standout features. However, adding optional nozzles for different materials could enhance versatility. Overall, a reliable tool with potential for improvement in customization options.

Jean Esposito (verified owner) –

In product prototyping, I’ve found the laser engraver invaluable for its precision and efficiency in handling custom wedding decorations. For instance, working with wood and acrylic materials, the engravings turned out smooth and detailed. A challenge arose with darker woods causing burn marks, but adjusting the power settings resolved this issue effectively.

The tool’s impact on workflow has been significant. It streamlined production processes compared to manual methods or CNC machines, saving time while maintaining high quality. Customer feedback has been overwhelmingly positive, praising the intricate details and polished finish of their orders. This investment not only enhanced our creative output but also provided a solid return through cost savings and improved customer satisfaction.

Min-jun Wang (verified owner) –

I’m super happy with how this fiber laser cutter handles acrylic! I used it to make some custom awards, and the cuts were so smooth and precise, no burns or rough edges at all. It’s been a game-changer for keeping my business running efficiently.

Barbara Jones –

Five stars for this laser engraver! The engraving precision is impeccable, and the results are stunning. The software is user-friendly, and operations are smooth. Fast engraving speed boosts my productivity. Solid build, highly reliable.