Fiber Laser Cutter | Laser Engraver: Comprehensive Guide

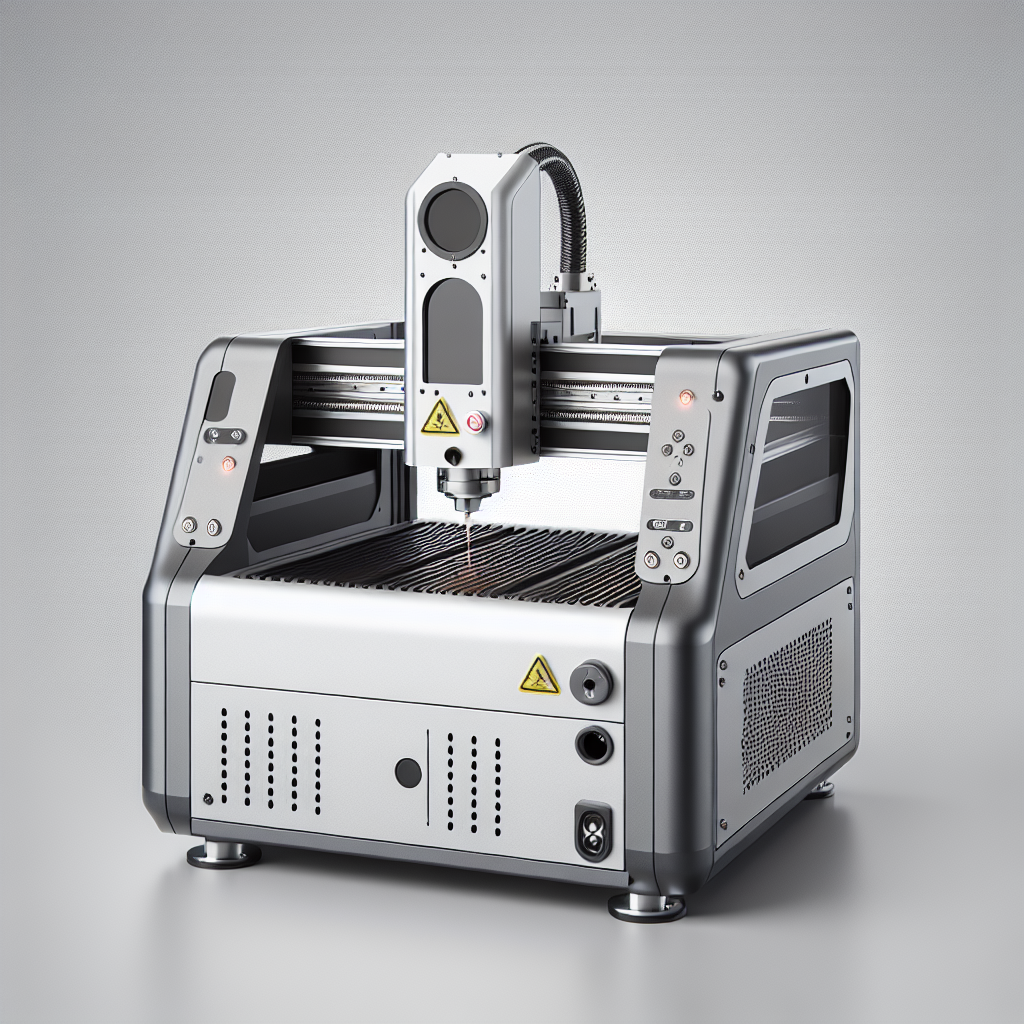

Fiber laser cutters and engravers are cutting-edge tools that have revolutionized the manufacturing and design industries. These devices utilize fiber lasers to provide precise, high-speed cutting and engraving capabilities across a wide range of materials. In this guide, we will explore the technical specifications, applications, advantages, and limitations of fiber laser cutters | laser engravers. Whether you are a hobbyist, a small business owner, or a large-scale manufacturer, understanding how these machines work can help you make informed decisions about their use in your projects.

Technical Specifications

Fiber laser cutters | laser engravers come with a variety of technical specifications that determine their performance and suitability for different tasks. Below are some key features to consider:

- Wavelength: Fiber lasers typically operate at a wavelength of 1064 nm, which is ideal for cutting and engraving metals and certain non-metallic materials.

- Power Range: These machines usually offer power outputs ranging from 20W to 5000W or more, depending on the intended application. Higher wattage units are better suited for heavy-duty industrial use.

- Cutting Speed: Cutting speeds can vary widely, but modern fiber laser cutters | laser engravers can achieve speeds of up to 100 m/min or higher, making them highly efficient for large-scale production.

- Material Compatibility: Fiber lasers are compatible with a wide range of materials, including steel, stainless steel, aluminum, brass, copper, and certain plastics. However, they may not be suitable for all materials, such as glass or certain composites.

- Precision: These machines offer high levels of precision, typically achieving cut accuracies within ±0.001 mm, making them ideal for intricate designs and complex patterns.

- Repetition Rate: The repetition rate refers to the number of pulses per second that the laser can produce. Higher repetition rates are beneficial for faster processing times.

Applications of Fiber Laser Cutters | Laser Engravers

Fiber laser cutters | laser engravers have a broad range of applications across various industries:

Hobby and Artistic Projects

- Creating custom engravings on jewelry, wooden signs, or decorative items.

- Precision cutting for model building,RC hobbies, and DIY projects.

Industrial Manufacturing

- Cutting sheet metal components for automotive, aerospace, and construction industries.

- Engraving serial numbers, barcodes, or logos onto products.

Prototyping and R&D

- Rapid prototyping of small parts and components.

- Testing and development of new designs with high precision.

Customization Services

- Personalized engraving for gifts, awards, and promotional items.

- Custom cutting for signage, furniture, and architectural elements.

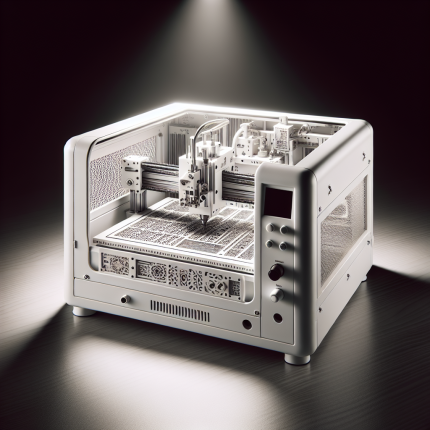

Advantages of Fiber Laser Cutters | Laser Engravers

- High Precision: The narrow beam diameter ensures clean cuts with minimal material waste.

- Speed and Efficiency: Compared to traditional cutting methods, fiber laser cutters | laser engravers offer faster processing times.

- Versatility: Capable of working with a wide range of materials, making them suitable for diverse applications.

- Low Maintenance: Fiber lasers are known for their durability and low maintenance requirements compared to other types of lasers.

- Energy Efficiency: These machines consume less energy than many traditional cutting tools, reducing operational costs.

Limitations and Considerations

While fiber laser cutters | laser engravers offer numerous benefits, they also have some limitations:

- Material Restrictions: They are not suitable for all materials, particularly those with high reflectivity or thermal conductivity like copper or gold.

- Initial Investment: High-quality fiber laser cutters | laser engravers can be expensive to purchase, although their long-term cost-effectiveness often justifies the investment.

- Safety Precautions: Working with lasers requires proper safety measures, including protective eyewear and controlled operating environments.

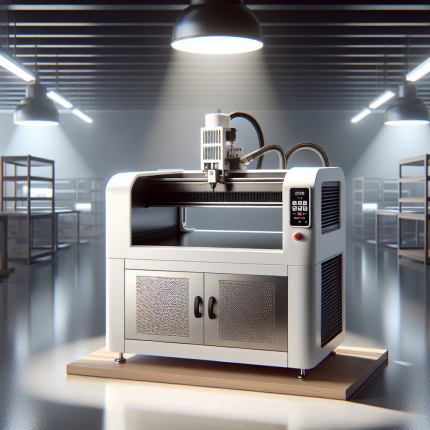

Maintenance and Care

To ensure optimal performance and longevity of your fiber laser cutter | laser engraver, regular maintenance is essential:

- Cleanliness: Keep the machine and its components clean to avoid dust or debris interfering with operations.

- Laser Head Inspection: Periodically inspect the laser head for any signs of wear or damage.

- Cooling System Check: Ensure that the cooling system is functioning properly to prevent overheating.

- Software Updates: Keep the machine’s software up to date to take advantage of the latest features and improvements.

FAQ Section

1. What is the difference between a fiber laser cutter and a CO2 laser cutter?

Fiber lasers use fiber optic technology to generate light, while CO2 lasers rely on gas-filled tubes. Fiber lasers are generally more efficient, faster, and require less maintenance compared to CO2 lasers. However, CO2 lasers may be better suited for cutting non-metallic materials like wood or plastic.

2. Can a fiber laser cutter | laser engraver work on all materials?

No, fiber lasers are not suitable for all materials. They perform best on metals and certain plastics but may struggle with highly reflective or conductive materials. Always check the machine’s specifications before using it on new materials.

3. How thick of a material can a fiber laser cutter | laser engraver cut?

The maximum thickness depends on the machine’s power output. Lower wattage units are suitable for thin materials, while high-power machines can handle thicker sheets of metal, often up to several centimeters in thickness.

4. What are the main advantages of using a fiber laser cutter | laser engraver over traditional cutting methods?

Fiber lasers offer higher precision, faster processing times, and lower operational costs compared to traditional cutting methods like plasma or oxy-fuel cutting. They also require minimal setup time and produce less waste material.

5. How do I ensure safe operation of a fiber laser cutter | laser engraver?

Always follow the manufacturer’s safety guidelines, wear protective eyewear, and operate the machine in a well-ventilated area to avoid inhaling fumes from cutting materials. Regular maintenance can also help prevent accidents caused by malfunctioning components.

Conclusion

Fiber laser cutters | laser engravers are powerful tools that have transformed the way we approach precision cutting and engraving tasks. Their versatility, efficiency, and high precision make them indispensable in both industrial and artistic applications. By understanding their technical specifications, advantages, limitations, and proper maintenance, you can maximize their potential and achieve outstanding results in your projects.

Whether you are looking to enhance your manufacturing capabilities or explore creative design possibilities, a fiber laser cutter | laser engraver is a valuable addition to any workshop or production facility. With continued advancements in technology, these machines will likely become even more versatile and efficient in the future.

Carlos Dubois (verified owner) –

The laser engraver excels in precision across various materials, delivering sharp engravings on wood, acrylic, and leather. Its speed is impressive for small to medium projects, though larger surfaces take longer than expected. The software interface is intuitive, with a clean layout that simplifies design uploads and adjustments. A standout feature is its ability to handle intricate patterns without distortion, making it ideal for custom jewelry boxes or signage. While the price-performance ratio is strong, investing in additional nozzles for varied applications would enhance versatility. Overall, this engraver balances quality and usability, suitable for both artistic and small-scale business needs.

Marco Cho (verified owner) –

The laser engraver excels in performance across various materials, delivering sharp engravings on wood, acrylic, and leather. Its precision is remarkable, with intricate details preserved even at high speeds. The setup process is straightforward, requiring minimal adjustments, and the intuitive software interface simplifies design uploads and customizations. A standout feature is its ability to handle complex projects like personalized jewelry boxes and signage without compromising quality. While it offers excellent value for its price, an optional upgrade for larger workspace capacity would enhance versatility for industrial applications.

Adriana Brown (verified owner) –

The laser engraver excels in versatility across materials, delivering crisp results on wood, acrylic, and leather with high precision. For instance, creating intricate wooden signs and sleek acrylic awards showcased its capability. The setup was straightforward, and the intuitive software interface facilitated quick project transitions, even for detailed vector graphics. Standout features include automatic adjustments for different materials, minimizing manual tweaking. However, occasional delays occur when switching materials, and limited support for certain file formats could be improved. Overall, it’s a robust tool with minor areas for enhancement, offering excellent value for precise engraving needs.

Sarah Lee (verified owner) –

The laser engraver excels in performance across various materials, delivering crisp details on wood and acrylic while maintaining speed for larger projects. Its high-speed galvanometric mirrors ensure precise cuts, ideal for intricate designs. The setup was straightforward, though the software interface could benefit from a more intuitive layout. Overall, it offers excellent value for hobbyists and small businesses seeking reliable engraving solutions with minimal learning curve.

Claudia Xu (verified owner) –

**Laser Engraver Experience Report**

As a craft store owner, I’ve integrated a laser engraver into my operations, enhancing both creativity and efficiency. Here’s my experience focusing on Specific Project Experience and Technical Performance:

—

**Specific Project Experience: Custom Shop Signs**

I recently created custom signs for a local café using acrylic and wood. The acrylic cut cleanly but required careful power settings to avoid melting, while the wood offered a beautiful charred finish with controlled burning. A challenge arose in achieving consistent depth on curved sections of the sign. This was resolved by adjusting the laser’s path speed, ensuring smoother cuts without over-burning.

—

**Technical Performance: Power and Precision**

The laser engraver demonstrated excellent power control across different materials. The software is intuitive, allowing easy adjustments for various projects. Features like air assist improved cut quality on acrylic, while variable speed settings helped maintain precision on wood. Compared to manual methods, this tool offers greater efficiency and accuracy, significantly reducing production time.

—

**Impact on Workflow and ROI**

The laser engraver has streamlined my workflow, enabling quicker turnaround times and higher-quality products. Customer feedback has been overwhelmingly positive, with clients appreciating the intricate details and consistent results. The return on investment is evident through increased project volume and customer satisfaction, making it a valuable asset to my business.

—

This tool has proven essential in enhancing both my creative output and operational efficiency, setting new standards for craftsmanship in my store.

Ling Horvat (verified owner) –

“I love this Fiber Laser Cutter/Engraver! It made creating my custom cutting board a breeze with precise cuts every time. Such a game-changer for adding that personal touch to home decor.”

William Jones –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly. Fast engraving speed boosts my productivity. Solid build, highly reliable.