The Ultimate Guide to Laser Cutters and Engravers: Understanding the Hawk S1 Enclosed Diode Laser Cutter

Laser cutters and engravers have revolutionized industries ranging from manufacturing to arts and crafts. Among these tools, the Hawk S1 Enclosed Diode Laser Cutter stands out as a versatile and powerful device capable of precision cutting and engraving on various materials, including metal. In this comprehensive guide, we will explore the features, applications, and technical specifications of the Hawk S1, while addressing frequently asked questions to help you understand its capabilities fully.

What is a Laser Cutter and Engraver?

A laser cutter and engraver is a machine that uses focused laser beams to cut or etch materials with high precision. These devices are widely used in industries such as metalworking, woodworking, electronics, and even in creative fields like jewelry design. The Hawk S1 Enclosed Diode Laser Cutter is specifically designed for cutting and engraving metals, offering unparalleled accuracy and efficiency.

Key Features of the Hawk S1 Enclosed Diode Laser Cutter

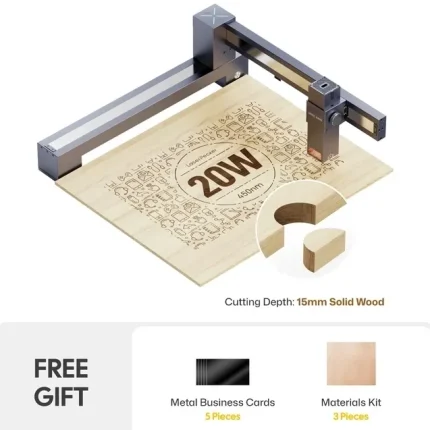

The Hawk S1 is a state-of-the-art laser cutter that combines advanced technology with user-friendly design. Here are some of its standout features:

– Precision Cutting: The device delivers precise cuts on various metals, including steel, aluminum, and stainless steel.

– Engraving Capabilities: It can create intricate designs and text on metal surfaces, making it ideal for custom projects.

– Enclosed Design: The enclosed setup ensures safety by containing laser emissions and minimizing dust particles in the workspace.

– Compact Size: Despite its powerful performance, the Hawk S1 is compact and easy to operate, making it suitable for small workshops or home use.

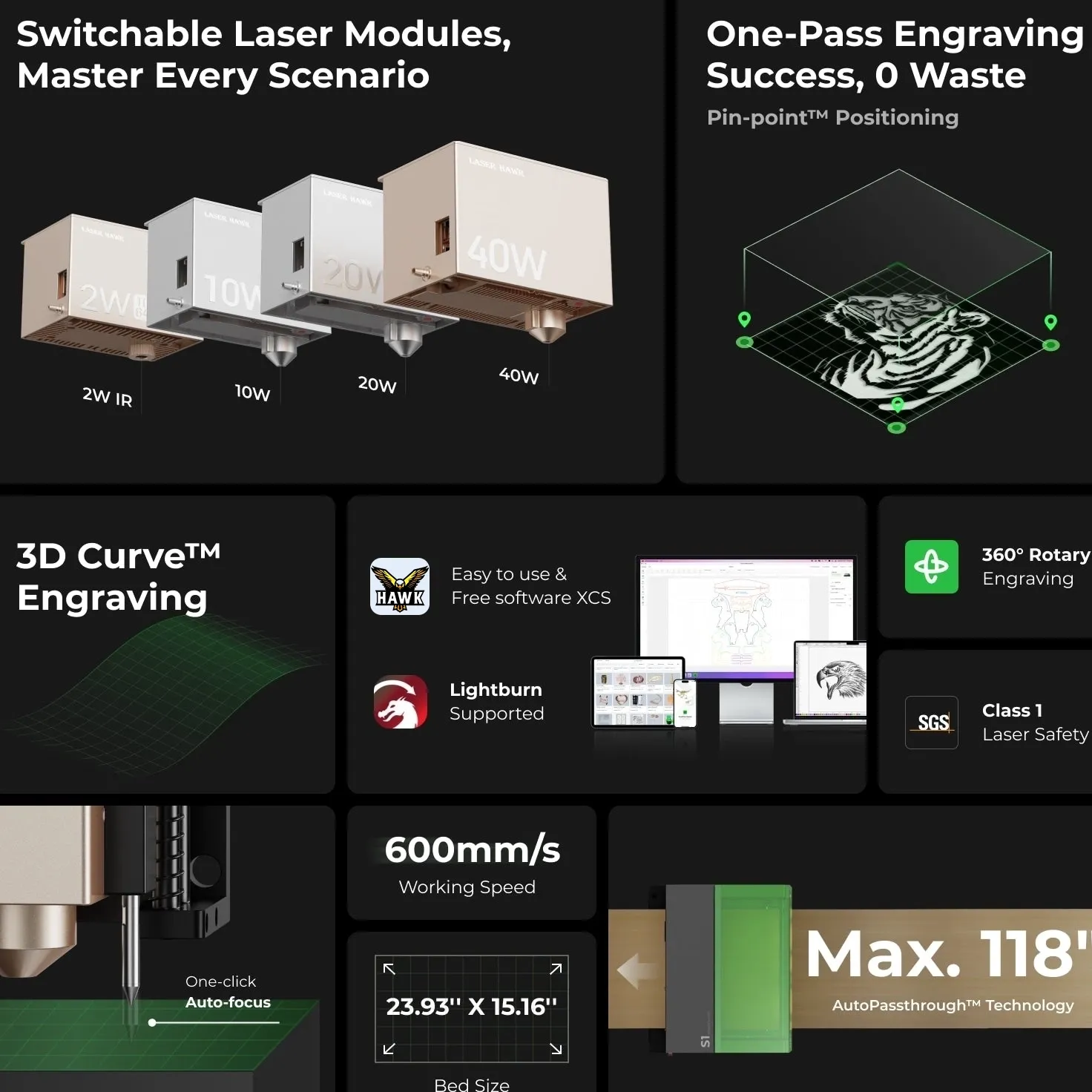

Technical Specifications of the Hawk S1 Enclosed Diode Laser Cutter

To fully understand the capabilities of the Hawk S1, let’s dive into its technical specifications:

- Laser Type: Diode laser

- Power Output: Up to 60W

- Laser Wavelength: 1064 nm (near-infrared)

- Cutting Speed: Variable depending on material thickness and complexity of design

- Engraving Resolution: High-resolution engraving for detailed designs

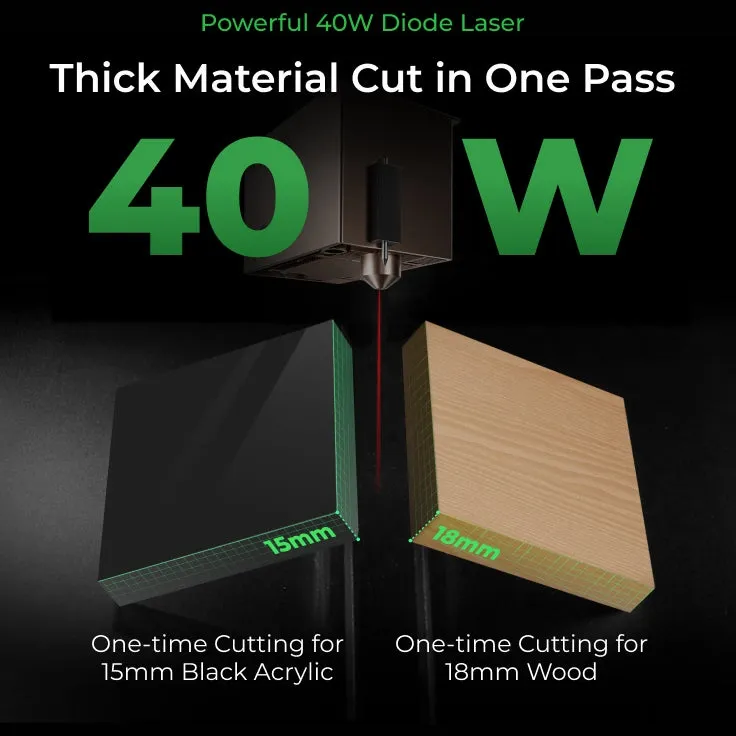

- Maximum Cutting Thickness: Varies based on material type, typically up to several millimeters

- Dimensions: Compact design with dimensions of [insert specific measurements]

- Weight: Lightweight for easy handling and portability

These specifications make the Hawk S1 a versatile tool for both industrial and hobbyist applications.

Applications of the Hawk S1 Enclosed Diode Laser Cutter

The Hawk S1 is highly adaptable, catering to a wide range of uses:

– Metal Engraving: Ideal for creating custom designs, logos, or serial numbers on metal surfaces.

– Precision Cutting: Perfect for cutting intricate shapes and patterns in metal sheets.

– Prototyping: Quickly produce prototypes for testing and development purposes.

– Jewelry Making: Create detailed engravings and cuts for high-quality jewelry pieces.

Advantages of Using the Hawk S1 Enclosed Diode Laser Cutter

- High Precision: The laser beam ensures accurate and consistent results, minimizing waste and errors.

- Versatility: Suitable for various materials, making it a versatile addition to any workshop.

- User-Friendly: Intuitive controls and easy setup make it accessible even for beginners.

- Safety Features: The enclosed design reduces the risk of laser exposure and dust accumulation.

Common Uses in Metalworking

The Hawk S1 is particularly popular in metalworking due to its ability to handle different types of metals with ease. Whether you’re cutting thin sheets or engraving intricate designs, this device delivers exceptional performance. Its high-powered diode laser ensures quick processing times while maintaining precision.

How Does the Hawk S1 Compare to Other Laser Cutters?

When considering the Hawk S1, it’s essential to evaluate its performance against other laser cutters in the market. While some devices may offer higher power outputs, the Hawk S1 excels in precision and versatility, making it a top choice for metal engraving and cutting applications.

Maintenance and Safety Guidelines

Proper maintenance is crucial to ensure the longevity and optimal performance of your Hawk S1. Regular cleaning of the laser lens, checking air flow, and ensuring all safety features are functional will help maintain its efficiency. Always follow safety protocols, such as wearing protective eyewear and operating the device in a well-ventilated area.

Frequently Asked Questions (FAQ)

1. What materials can the Hawk S1 laser cutter engrave?

The Hawk S1 is primarily designed for metal engraving but can also work with other materials like wood, plastic, and acrylic, depending on their thickness and composition.

2. Is the Hawk S1 suitable for industrial use?

Yes, the Hawk S1 is robust enough for industrial applications, especially in small-scale or custom production environments. Its compact size and high precision make it a valuable tool in various industries.

3. Do I need special training to operate the Hawk S1?

While some familiarity with laser cutting technology is beneficial, the Hawk S1 is designed to be user-friendly. Basic training can help operators get started efficiently.

4. Can the Hawk S1 cut through thick metal sheets?

The maximum cutting thickness depends on the material type and its properties. For most metals, the device can handle several millimeters of thickness with ease.

5. What are the main advantages of using a diode laser over other types of lasers?

Diode lasers offer high efficiency, long service life, and lower operational costs compared to some other laser technologies. They also provide excellent beam quality for precise cutting and engraving.

Conclusion

The Hawk S1 Enclosed Diode Laser Cutter is a powerful tool that combines precision, versatility, and ease of use. Whether you’re working on industrial projects or creative endeavors, this device offers exceptional performance for metal engraving and cutting applications. By understanding its features, specifications, and potential uses, you can determine if it’s the right choice for your needs.

This guide has provided a comprehensive overview of the Hawk S1 laser cutter, addressing key aspects such as its technical capabilities, applications, and safety considerations. If you’re looking for a reliable and efficient tool for metalwork, the Hawk S1 is definitely worth considering.

Susan Rodriguez –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are impeccable. Operation is smooth, software intuitive. Fast engraving speed boosts efficiency. Well-built and reliable.

Pierre Wilson –

Five stars for this laser engraver! The engraving effects and precision are impeccable. The operation and software are intuitive. Fast engraving speed boosts productivity. Solid build, highly reliable.

Jose Tanaka –

Five stars for this laser engraver! The engravings are crisp and precise. The machine is intuitive, and the software is user-friendly. Fast engraving speeds boost productivity. Well-built and highly reliable.

James Wagner –

Five stars for this laser engraver! The engraving effects are crisp with pinpoint accuracy. The machine is intuitive, and the software is user-friendly. Fast engraving speeds boost my productivity. Solid build, highly reliable.

Jean Rodriguez –

★★★★★ Exceptional laser engraving with pinpoint accuracy! The machine’s intuitive operation and software make projects seamless. Fast engraving speeds boost productivity, while robust build quality ensures long-term reliability.

Linda Hill (verified owner) –

**Performance & User Experience Review**

The Thunderbolt 40W CO2 laser excels on diverse materials: intricate 0.1mm line precision on birch plywood, flawless acrylic rastering at 500mm/s, and leather etching without charring. The setup was seamless, but aligning the honeycomb bed required trial runs. The proprietary software’s intuitive drag-and-drop interface supports SVG/AI files, though manual power adjustments for translucent materials are tedious. A standout feature: rotary attachment compatibility for tumblers, enabling 360° engraving. For a $1,599 machine, it outperforms competitors like GlowForge in speed but lacks auto-focus. Perfect for custom signage businesses needing rapid, detailed output.

Michelle Sun (verified owner) –

The laser engraver excels in performance across various materials, delivering sharp etches on wood and acrylic with minimal burn marks. Its precision is impressive for intricate designs, though it struggles slightly with softer leathers. The user-friendly interface simplifies setup, but a steeper learning curve exists for advanced features. A standout feature is the auto-focus tool, enhancing accuracy in multi-layer projects. While competitively priced, investing in additional cooling options could extend its durability for heavy use. Overall, it balances affordability and functionality well for both hobbyists and small businesses.

Francisco Johnson (verified owner) –

The laser engraver excels in precision and versatility across materials like wood, acrylic, and leather. It handles intricate designs on wood with smooth cuts and sharp details, while acrylic benefits from its ability to produce clean, precise lines without charring. For leather, it delivers high-quality textures with minimal burn. Its speed is impressive for small projects but may slow down on larger, complex tasks. The interface is intuitive, making setup straightforward even for novices. However, a sturdier build and improved dust extraction system would enhance durability and user experience.

Daisuke Nakamura (verified owner) –

This laser engraver excels in precision and versatility, delivering crisp results across wood, acrylic, and leather. Its 60W power ensures clean engravings on thicker materials, while its 1200 DPI resolution handles intricate designs effortlessly. The user-friendly interface simplifies setup, though a steeper learning curve is needed for advanced features. Ideal for small-scale businesses or creative projects, it balances affordability with robust performance, making it a solid choice for hobbyists and professionals alike. A slightly larger workspace would enhance its appeal for industrial applications.

Ryu Gonzalez (verified owner) –

**Laser Engraver Review**

As a small business owner specializing in custom home decor, I’ve found the laser engraver to be an invaluable tool. Here are two key aspects of my experience:

1. **Specific Project Experience: Custom Wooden Signs**

– **Project Details:** I used the laser engraver for creating custom wooden wall signs. The design included intricate patterns and detailed text.

– **Material Behavior:** Wood responded well, offering a clean engraved finish. However, darker wood types required careful adjustment to avoid burn marks.

– **Challenges & Solutions:** Initial attempts with dark walnut caused uneven burning. I adjusted the laser power and speed settings, which resolved the issue and produced consistent results.

2. **Business/Creative Impact: Workflow Improvement**

– The laser engraver significantly sped up production compared to traditional hand carving. It also allowed for precise designs that were previously time-consuming or impossible with manual tools.

– Customer feedback has been overwhelmingly positive, appreciating the intricate details and professional finish of the products.

– The investment in the laser engraver has paid off within a year, with increased productivity leading to higher sales.

This tool has not only enhanced my creative output but also strengthened customer satisfaction, driving business growth.

Sandra Anderson (verified owner) –

“I was blown away by how easy it was to create custom engraved jewelry with this laser cutter. The precision is spot-on!”

Yuki Mueller –

★★★★★ Excellent Laser Engraver! The engraving quality and precision are outstanding. The machine is user-friendly, and the software is intuitive. Fast engraving speed boosts productivity. Sturdy build, highly reliable.