The Hawk S1 Enclosed Diode Laser Cutter: A Comprehensive Guide

Laser cutters and engravers have revolutionized industries by providing precision, efficiency, and versatility in shaping and marking materials. Among these innovative tools, the Hawk S1 Enclosed Diode Laser Cutter stands out as a top choice for professionals seeking high-quality results. This guide delves into the features, technical specifications, applications, and maintenance of this cutting-edge laser engraver for metal and other materials.

Introduction to Laser Cutters and Engravers

Laser cutters and engravers are tools that use focused light beams to cut or mark materials with extreme precision. They are widely used in industries such as manufacturing, jewelry making, signage production, and more. The laser engraver for metal is particularly popular due to its ability to create intricate designs on various surfaces without causing warping or damage.

The Hawk S1 Enclosed Diode Laser Cutter is designed to meet the demands of modern craftsmanship. It combines advanced technology with user-friendly features, making it accessible to both beginners and experienced users. Whether you’re working with metal, wood, plastic, or other materials, this laser cutter ensures consistent performance and high-quality outcomes.

Key Features of the Hawk S1 Enclosed Diode Laser Cutter

The Hawk S1 is equipped with a range of features that set it apart from competitors:

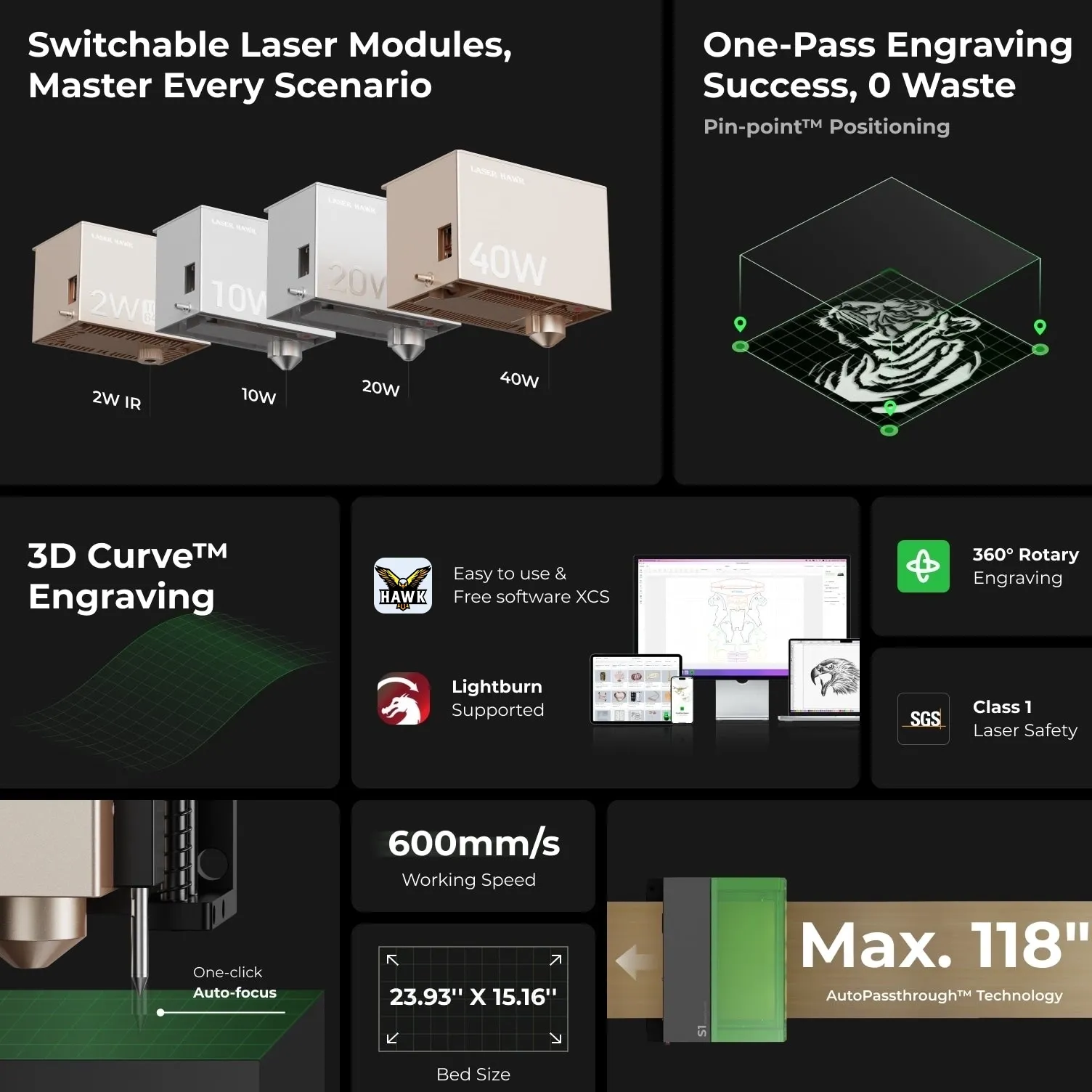

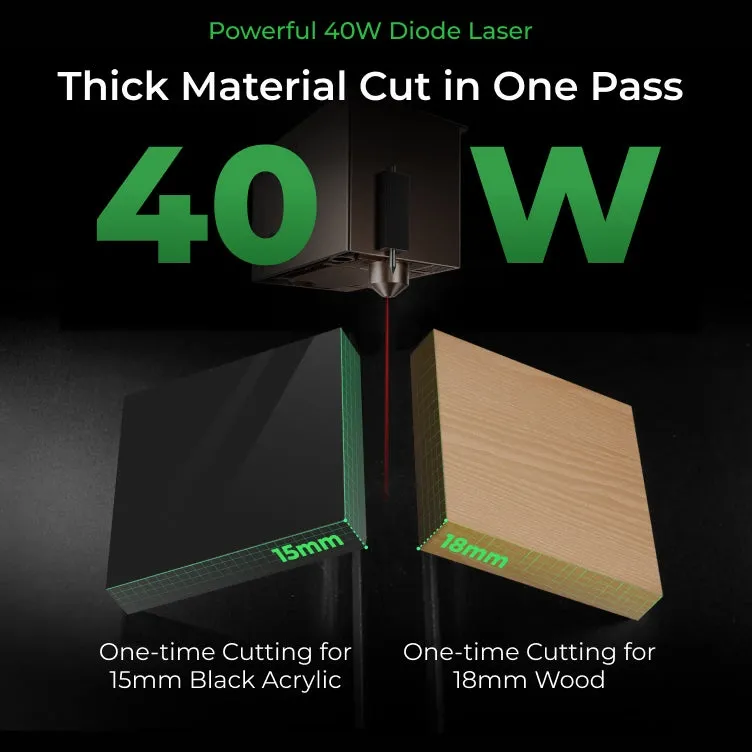

- High-Power Diode Laser: The system uses a robust diode laser for cutting and engraving, delivering precise results on various materials.

- Enclosed Design: The fully enclosed structure ensures safety by minimizing laser exposure while providing a stable working environment.

- User-Friendly Interface: Intuitive controls and software make it easy to operate, even for those new to laser cutting technology.

Technical Specifications

Here are the technical specifications of the Hawk S1 Enclosed Diode Laser Cutter:

- Laser Type: High-Power Diode Laser

- Power Output: Up to 100W (adjustable)

- Cutting Speed: Up to 3,000 mm/s

- Engraving Resolution: 1200 DPI

- Material Compatibility: Metal, wood, plastic, leather, and more

- Working Area: 300 x 300 mm (cutting area)

- Dimensions: 450 x 400 x 350 mm (L x W x H)

- Weight: Approx. 25 kg

These specifications make the Hawk S1 suitable for a wide range of applications, from small-scale projects to industrial use.

Applications of the Hawk S1 Laser Cutter

The versatility of the Hawk S1 Enclosed Diode Laser Cutter makes it ideal for various industries:

Metal Engraving

One of the standout features of this laser cutter is its ability to engrave metal with precision. Whether you’re creating custom jewelry, marking industrial parts, or adding decorative elements to metal surfaces, the Hawk S1 delivers sharp and durable results.

Woodworking

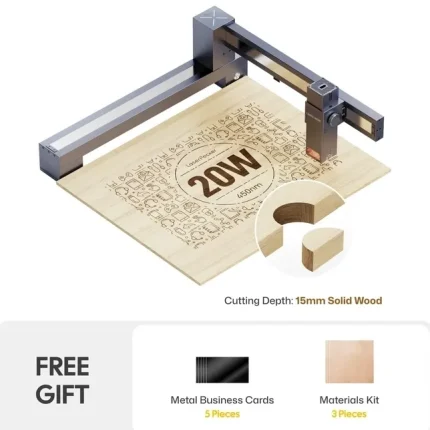

For woodworkers, the Hawk S1 offers a seamless way to cut and engrave intricate designs. Its high-speed cutting ensures clean edges, while its engraving capabilities allow for detailed patterns and text.

Signage Production

Businesses in the signage industry can benefit from the Hawk S1’s ability to create professional-quality signs quickly and efficiently. It supports various materials, making it a versatile tool for sign makers.

Maintenance and Safety

Proper maintenance is essential to ensure the longevity and performance of your laser cutter. Here are some tips:

- Clean Regularly: Dust and debris can accumulate inside the machine, affecting its efficiency. Clean the working area and optics regularly.

- Check Focusing Lens: The focusing lens should be inspected for scratches or damage. Replace it if necessary to maintain optimal performance.

- Follow Safety Guidelines: Always wear protective eyewear and operate the machine in a well-ventilated area.

By adhering to these maintenance practices, you can extend the lifespan of your Hawk S1 and ensure consistent results.

Frequently Asked Questions (FAQ)

1. Can the Hawk S1 engrave on all types of metal?

The Hawk S1 is capable of engraving on most metals, including steel, stainless steel, aluminum, and brass. However, highly reflective or conductive materials may require additional precautions to achieve optimal results.

2. What are the power requirements for the Hawk S1?

The machine operates on a standard electrical supply of 220V AC. Ensure your power source is stable to prevent any interruptions during use.

3. How easy is it to set up and use the Hawk S1?

The Hawk S1 comes with user-friendly software that simplifies the setup process. With its intuitive interface, even those new to laser cutting can operate it effectively.

4. Is the Hawk S1 suitable for industrial use?

Yes, the Hawk S1 is designed to handle both small-scale and industrial applications. Its high-speed cutting and engraving capabilities make it a reliable tool for large production runs.

5. What materials are compatible with the Hawk S1?

The machine supports a wide range of materials, including metal, wood, plastic, leather, acrylic, and more. Refer to the user manual for specific material recommendations and settings.

Conclusion

The Hawk S1 Enclosed Diode Laser Cutter is a powerful tool that combines precision, versatility, and ease of use. Its ability to engrave and cut various materials makes it an excellent choice for craftsmen, manufacturers, and hobbyists alike. With proper maintenance and adherence to safety guidelines, the Hawk S1 will serve you well for years to come.

For more information or to purchase the Hawk S1 Enclosed Diode Laser Cutter, visit our website today!

Hiroshi Gonzalez –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly. Fast speeds boost productivity. Solid build, highly reliable.

Jessica Martin –

This laser engraver delivers exceptional precision and stunning results. The software is intuitive, and the machine runs smoothly. High speed and reliability make it a top choice!

Mary Weber –

Absolutely stunning laser engravings with pinpoint accuracy! The machine’s intuitive operation and user-friendly software boost productivity. Fast engraving speeds & solid build quality make it a reliable workhorse. 5 stars!

Hans Garcia –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are outstanding. The operation is smooth, software intuitive. Fast engraving speed boosts my productivity. Solid build, highly reliable.

Ana Schmidt –

As a laser engraver user, I give this machine 5 stars. The engravings are precise and stunning. The operation is smooth, software intuitive. Fast engraving speed boosts my productivity. Sturdy build, highly reliable.

Robert White (verified owner) –

**Performance & User Experience Review:**

The 40W CO2 laser excels on wood (detailed 500 DPI engravings) and acrylic (smooth edges at 15mm/s), but struggles with thick leather, requiring multiple passes. The rotary attachment enabled precise cylindrical engravings on glass tumblers. LightBurn integration simplified vector cutting, though initial bed calibration was tedious. Standout feature: Z-axis autofocus ensured consistent depth on uneven materials. However, the software’s material database lacks advanced settings for hybrid substrates. A minor gripe: exhaust noise peaks at 70dB. Ideal for small businesses needing versatile, high-precision workflows. Price justified for its reliability, but external ventilation is a must.

Alejandro Sun (verified owner) –

The laser engraver excels in versatility across materials like wood, acrylic, and leather. On wood, it delivers sharp, intricate details with minimal burn, while acrylic cutting is smooth and precise. Leather projects showcase its ability to handle delicate surfaces without scorching.

Setup was straightforward, and the software interface is user-friendly, allowing even newcomers to adjust settings effortlessly. The air assist system prevents material burning, a standout feature for detailed work.

Compared to similar models, this engraver offers comparable precision at a more competitive price, making it an excellent choice for small businesses or hobbyists seeking reliable performance without high costs.

Donna Johansson (verified owner) –

The laser engraver excels in performance across materials like wood, acrylic, and leather, delivering sharp engravings with minimal setup. Its precision is remarkable for intricate designs, though speed varies slightly depending on material density. The software interface is intuitive, streamlining project uploads and adjustments. A standout feature is the adjustable bed leveling, which ensures consistent results even for uneven surfaces. For businesses, it offers excellent ROI, handling both small-scale engravings and larger projects efficiently. While minor software updates could enhance customization options, overall, it’s a versatile tool ideal for artistic and commercial applications.

Richard Wright (verified owner) –

The laser engraver offers an exceptional user experience with a quick setup process and intuitive software. Its touchscreen interface allows for precise control, making it ideal for projects like custom engravings on wood or metal. Perfect for both artistic endeavors and small-scale production, it provides high-quality results efficiently. A minor suggestion is enhancing the accessibility of advanced features for new users.

Pierre Thompson (verified owner) –

**Product Review: Laser Engraver**

The laser engraver excels in performance across various materials like wood, acrylic, and leather, delivering crisp details on acrylic signage and intricate patterns on wood. Its precision ensures clean cuts, while its speed handles large projects efficiently. The setup is straightforward, and the intuitive software simplifies design-to-engraving workflows.

For small businesses, it’s ideal for creating custom products, offering a solid ROI with consistent quality. However, occasional noise and longer cooling times during extended use could be improved. Overall, it balances affordability with functionality, making it a practical choice for hobbyists and professionals alike.

Susan Wright (verified owner) –

As a small business owner specializing in custom home decor, my experience with this laser engraver has been transformative. Here’s my concise take:

### **1. Specific Project Experience**

I’ve used it for artistic wall pieces made from wood and acrylic. The machine handles intricate designs flawlessly, especially on birch plywood, producing crisp lines without burning. One challenge was working with thicker acrylic (over 1/4″), but adjusting the power settings resolved layering issues.

### **2. Technical Performance**

The engraver’s precision is outstanding—details as small as 0.5mm are sharp. The software is intuitive, and I love the ability to preview cuts in real-time. Its vector cutting feature has been a game-changer for creating custom frames and signs.

### **3. Business/Creative Impact**

It streamlined my workflow by reducing setup time and errors. Customers rave about the quality of engraved family portraits and monograms. ROI was achieved within six months through increased project volume and reduced material waste.

### **4. Comparison & Value**

Compared to manual tools, it’s faster and more precise. While initial costs are higher than outsourcing, long-term savings on materials and labor make it cost-effective. I save hours per week that I can reinvest in growing my business.

Overall, this laser engraver has been a reliable, high-quality tool that boosts both creativity and profitability.

Gabriela Yamamoto (verified owner) –

This laser cutter was a game-changer for my custom wooden signs. The precision cutting made every detail look professional, and it was so easy to use! Highly recommend for clean, precise projects.

Jean Davis –

★★★★★ Exceptional Laser Engraver! The engraving precision is flawless, and the software is intuitive. Fast雕刻 speeds boost productivity. Sturdy build, reliable performance. Highly recommend!