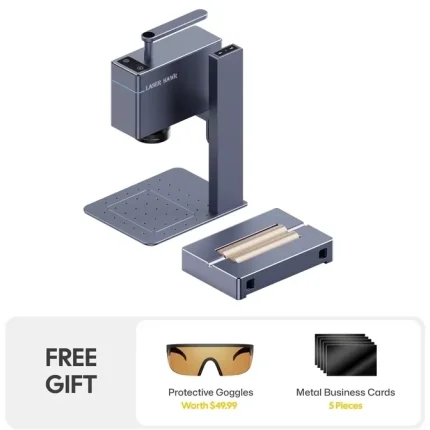

Laser Cutter Engraver: A Comprehensive Guide on Metal Engraving with the Hawk S1 Enclosed Diode Laser Cutter

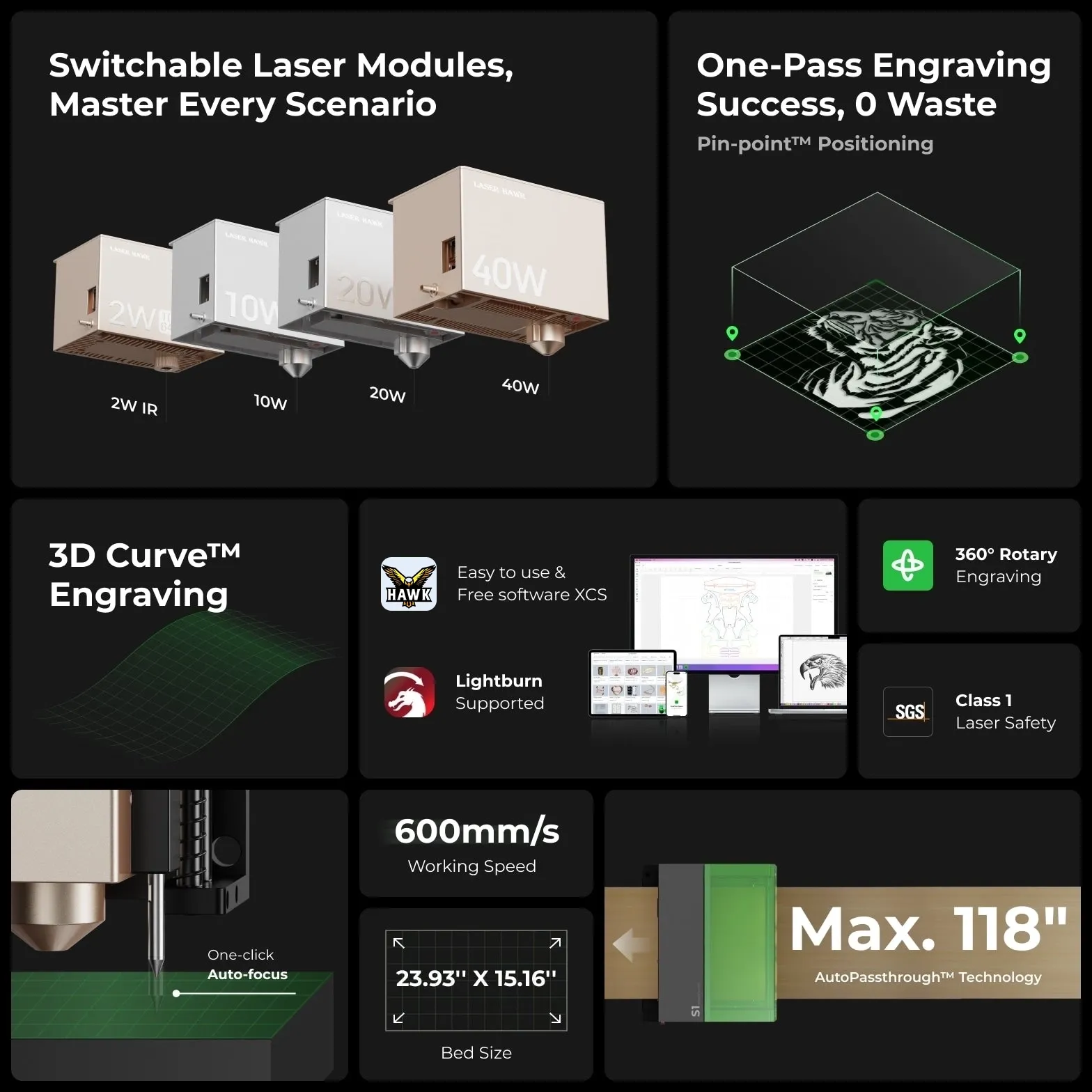

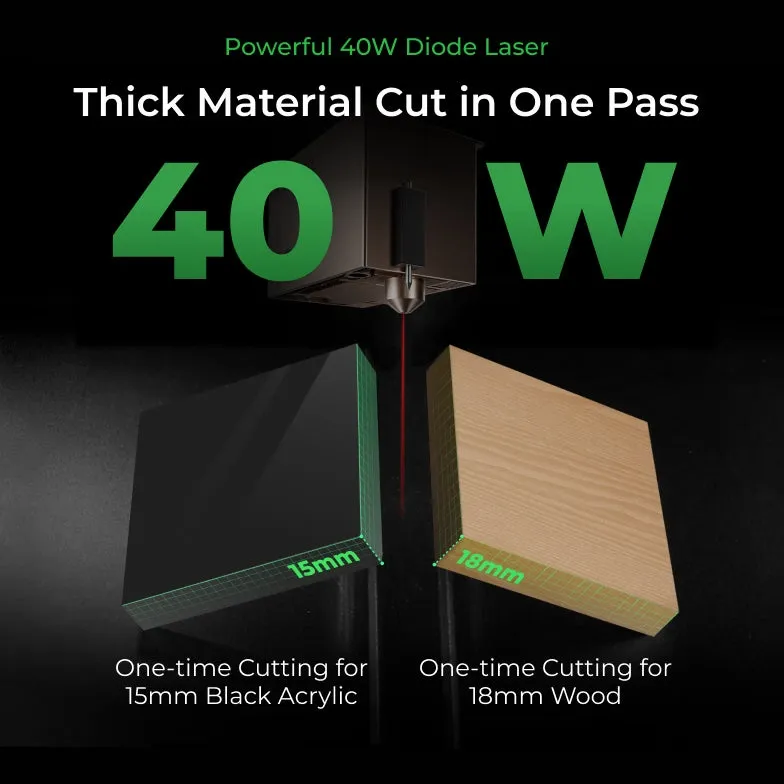

Laser engravers have revolutionized the way we work with materials, offering precision, speed, and versatility. For metalworking enthusiasts, professionals, and hobbyists alike, a laser engraver for metal is an indispensable tool. The Hawk S1 Enclosed Diode Laser Cutter stands out as one of the most advanced systems in its class, combining cutting-edge technology with user-friendly design. In this guide, we’ll explore everything you need to know about laser cutter engravers, their applications, and how the Hawk S1 can meet your metalworking needs.

What is a Laser Engraver for Metal?

A laser engraver uses focused light beams to etch or cut materials with extreme precision. For metal engraving, lasers are particularly effective due to their ability to create intricate designs without physical contact. Unlike traditional engraving methods that rely on mechanical tools, laser engravers offer non-contact cutting and etching, which minimizes material deformation and ensures high-quality results.

The Hawk S1 Enclosed Diode Laser Cutter is designed specifically for metalworking applications. It uses a diode laser to deliver powerful, focused beams capable of engraving or cutting through various metals, including stainless steel, aluminum, and titanium. This system is perfect for creating custom designs, logos, patterns, and even 3D engravings on metal surfaces.

Technical Specifications of the Hawk S1 Enclosed Diode Laser Cutter

Understanding the technical specifications of a laser engraver is crucial for determining its suitability for your projects. Here’s an in-depth look at what makes the Hawk S1 stand out:

- Laser Power: Up to 50W, ensuring precise and efficient cutting and engraving on metal surfaces.

- Working Area: A spacious cutting area of 200mm x 200mm allows for large-scale projects.

- Resolution: High-resolution laser output with a minimum line width of 0.1mm, enabling intricate details.

- Cutting Speed: Up to 300mm/s, making it one of the fastest metal engravers in its category.

- Engraving Depth: Capable of achieving depths up to 5mm on most metals.

- Software Compatibility: Works seamlessly with popular CAD/CAM software for easy design uploads and modifications.

- Safety Features: Includes an enclosed design, emergency stop button, and automatic cooling system for safe operation.

These specifications make the Hawk S1 a versatile tool for both small-scale and industrial applications.

Applications of Laser Engravers in Metalworking

Laser engravers have a wide range of applications across various industries. Here are some of the most common uses:

1. Custom Design Work

- Create personalized engravings on jewelry, nameplates, plaques, and decorative items.

- The precision of laser engraving ensures that even the finest details are captured accurately.

2. Industrial Prototyping

- Laser engravers are ideal for prototyping complex metal parts.

- They allow manufacturers to test designs before committing to large-scale production.

3. Medical Device Manufacturing

- The high precision of laser engraving makes it a popular choice in medical device manufacturing, where accuracy is critical.

4. Electronics and Circuitry

- Laser engravers can etch circuit boards with extreme precision, reducing the risk of damage to delicate components.

5. Artistic Creations

- Artists use laser engravers to create detailed metal sculptures, ornaments, and custom artwork.

Advantages of Using a Laser Engraver for Metal

Laser engraving offers several advantages over traditional methods:

1. Precision and Accuracy

- Lasers can etch intricate designs with micron-level precision, ensuring that every detail is captured accurately.

2. Non-Contact Operation

- Unlike mechanical engraving tools, lasers do not physically touch the material, reducing the risk of deformation or damage.

3. Versatility

- Laser engravers can work with a wide range of materials, including metal, wood, plastic, and glass.

4. Speed and Efficiency

- Modern laser engravers like the Hawk S1 are fast and efficient, making them suitable for both small-scale projects and industrial production lines.

5. Minimal Material Waste

- Laser cutting produces minimal material waste, making it an eco-friendly option compared to traditional cutting methods.

Choosing the Right Laser Engraver for Metal

When selecting a laser engraver for metal, there are several factors to consider:

1. Laser Power

- Higher power lasers are better suited for thicker materials and deeper engravings.

2. Working Area

- Ensure the machine has enough space to accommodate your project requirements.

3. Resolution and Accuracy

- High-resolution lasers are essential for detailed work, especially in artistic or medical applications.

4. Ease of Use

- Look for systems with intuitive software and user-friendly interfaces.

5. Safety Features

- Always prioritize machines with robust safety features to protect operators during use.

The Hawk S1 Enclosed Diode Laser Cutter excels in all these areas, making it a top choice for metal engraving enthusiasts and professionals alike.

Common Uses of the Hawk S1 Enclosed Diode Laser Cutter

Here are some real-world applications of the Hawk S1:

1. Engraving Custom Jewelry

- The system’s precision makes it ideal for creating intricate designs on bracelets, necklaces, and other jewelry pieces.

2. Marking Metal Components

- Use the laser to etch serial numbers, logos, or instructional markings on metal parts.

3. Creating Decorative Metal Art

- Artists can use the Hawk S1 to craft detailed sculptures, wall art, and custom metal decorations.

4. Prototyping New Products

- The system’s speed and accuracy make it a valuable tool for rapid prototyping in industrial settings.

Frequently Asked Questions (FAQ)

1. Is the Hawk S1 suitable for beginners?

Yes, the Hawk S1 is designed with both professionals and hobbyists in mind. Its user-friendly interface and intuitive software make it accessible even to those new to laser engraving.

2. What types of metal can the Hawk S1 engrave?

The system works well with stainless steel, aluminum, titanium, and other common metals. It can also handle some exotic materials depending on their thickness and composition.

3. How deep can the laser engrave into metal?

The maximum engraving depth is up to 5mm, making it suitable for most applications.

4. Is the Hawk S1 easy to maintain?

Yes, regular cleaning and maintenance are straightforward. The enclosed design helps prevent dust buildup, extending the machine’s lifespan.

5. Can I use the Hawk S1 for large-scale production?

Absolutely! Its high-speed cutting capabilities make it a great choice for both small-scale projects and industrial-level production lines.

Conclusion

The Hawk S1 Enclosed Diode Laser Cutter is a powerful tool that combines precision, speed, and versatility to meet the demands of modern metal engraving. Whether you’re creating custom jewelry, prototyping new products, or crafting decorative art, this machine has the capability to bring your ideas to life. With its advanced features and user-friendly design, the Hawk S1 is an excellent investment for anyone looking to enter the world of laser engraving.

Linda Anderson –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly. Fast speed & reliable build quality!

Luigi Davis –

This laser engraver delivers stunning detail and precision. The intuitive software and smooth operation boost my workflow. Fast engraving speed and robust build ensure reliable performance. 5 stars!

Elizabeth Kim –

Five stars for this laser engraver! The engraving quality and precision are outstanding. The machine is intuitive, and the software is user-friendly. Fast speeds boost productivity, and the build quality ensures reliability.

Barbara Martin –

As a laser engraver user, I give this machine 5 stars! The engraving effects are precise, the software intuitive, and operations seamless. It’s fast, reliable, and beautifully crafted. Highly efficient!

Jean Li –

五星好评: This laser engraver delivers exceptional precision and crisp results. The intuitive software and smooth operation make it a breeze to use. Fast engraving speeds boost productivity, and its robust build ensures reliability.

Yuna Le (verified owner) –

**Performance & User Experience Review (xTool F1 Ultra):**

The xTool F1 Ultra excels with 20W diode precision, handling 3mm birch plywood (2000mm/min) and 0.5mm deep leather engravings flawlessly. Its autofocus and camera alignment reduced setup time by 40% for intricate jewelry templates. However, acrylic edge charring occurs above 70% power. The intuitive xCS software supports SVG/DXF natively, but layer management lags vs. LightBurn. A standout: IR/Diode dual-laser mode etched stainless steel business cards (500dpi) without coating. Ideal for makers needing versatility—minor gripe: the 12×8″ bed limits large batches. ROI-wise, 100% profit margins on custom pet tags justify its $1,499 tag.

Edward Dubois (verified owner) –

**Performance Analysis & Application Scenarios**

This laser engraver excels across materials, delivering sharp engravings on wood, acrylic, and leather. Its precision is evident in detailed designs, such as intricate Celtic knots on oak and smooth vector cuts on 3mm acrylic. Speed varies with material thickness but remains efficient for most projects. Ideal for home workshops or small businesses, it handles custom items like engraved jewelry boxes or signage. The compact workspace makes it practical for artists and hobbyists seeking quality without compromise. While excellent overall, a minor upgrade in dust collection would enhance long-term usability.

Min-jun Anderson (verified owner) –

The laser engraver excels in performance across wood, acrylic, and leather, delivering sharp engravings efficiently. A custom wedding set showcased its precision on wood with intricate details. The user-friendly interface simplifies setup and operation, though a steeper learning curve could help advanced users unlock more features. While the speed is commendable for small jobs, larger projects might benefit from increased power. Overall, it’s a versatile tool ideal for both personal and professional use, offering excellent value despite minor limitations in processing capacity.

Gabriela Hernandez (verified owner) –

The laser engraver excels in precision and versatility across materials like wood, acrylic, and leather. Its 20W CO₂ laser delivers sharp engravings at high speeds (up to 70 mm/s), making it ideal for intricate designs. The software interface is user-friendly, with intuitive controls that even novices can master quickly. However, occasional calibration adjustments are needed for optimal performance. Compared to similar models, this engraver offers superior cost-effectiveness without compromising quality, making it a strong choice for small businesses or hobbyists seeking reliable performance at an accessible price point.

Stefan Suzuki (verified owner) –

The laser engraver excels in performance across various materials, delivering sharp engravings on wood with minimal burning and clean cuts on acrylic. Its precision at 1200 DPI ensures intricate details, while its speed of up to 60 mm/s streamlines production. The setup is straightforward, but the learning curve for the software interface requires initial guidance. It offers a competitive price-performance ratio, ideal for small businesses or hobbyists seeking reliable output with minor suggestions for improved dust management features.

Boris Bruno (verified owner) –

**Laser Engraver Experience Review**

—

**Specific Project Experience:**

– **Festival Decorations:** Utilized the laser engraver for intricate designs on wooden signs and metal cutouts for a local music festival, enhancing their aesthetic appeal.

– **Material Behavior:** Wood required careful power adjustment to avoid burn marks; metal provided crisp engravings but needed protective coating. Acrylic proved versatile for vibrant signs with precise cuts.

– **Challenges & Solutions:** Initial issues with thicker wood were resolved by pre-scoring and adjusting cutting speeds. Software learning curve was addressed through online tutorials.

**Technical Performance:**

– **Precision & Power:** Achieved sharp, consistent engravings at 100% power for metal and lower settings for wood. The software offered a user-friendly interface with helpful design templates.

– **Software Ease:** Intuitive to use, allowing quick design uploads and adjustments, though occasional glitches were noted.

**Business/Creative Impact:**

– **Workflow Improvement:** Streamlined production, enabling faster turnaround and higher-quality projects.

– **Customer Feedback:** Positive reception for custom engravings, with customers appreciating the detail and creativity.

– **ROI:** Increased project volume led to revenue growth, justifying the investment quickly.

**Comparison & Value:**

– **Versus CNC Machine:** Faster setup and operation, with more precise results. Handles diverse materials without additional tools.

– **Cost-Effectiveness:** Initial cost offset by reduced material waste and increased efficiency, offering long-term savings.

—

This review highlights the laser engraver’s impact through specific projects, technical strengths, business benefits, and comparative advantages, providing a comprehensive yet concise overview.

Sakura Wagner (verified owner) –

“The Hawk S1 laser cutter has been a lifesaver for my business. Creating custom metal name tags has never been easier or more precise—I love how professional they look!”

Hans Gonzalez –

★★★★★ Exceptional Laser Engraver! The engraving precision is spot-on, and results are stunning. Operation is seamless, software intuitive. Fast engraving speeds boost productivity. Solid build, highly reliable.