The Ultimate Guide to Laser Cutters and Engravers: Understanding the Hawk S1 Enclosed Diode Laser Cutter

Laser cutters and engravers have revolutionized modern manufacturing, offering precision and versatility across industries. If you’re looking for a reliable tool that combines power with accuracy, the Hawk S1 Enclosed Diode Laser Cutter stands out as a top contender. Designed for metal cutting and engraving, this device is perfect for hobbyists, small businesses, and industrial applications alike.

In this comprehensive guide, we’ll dive into what makes laser cutters like the Hawk S1 so effective, explore their technical specifications, discuss their advantages over traditional methods, and answer common questions to help you make an informed decision. Whether you’re new to laser cutting or seeking to upgrade your current setup, this article has everything you need to know.

What is a Laser Cutter?

A laser cutter is a machine that uses focused light beams (lasers) to cut or engrave materials with extreme precision. Unlike traditional cutting methods, which rely on mechanical tools, laser cutting offers unparalleled accuracy and adaptability. It’s widely used in industries like metal fabrication, woodworking, electronics, and even artistry due to its ability to handle intricate designs and complex patterns.

How Does a Laser Cutter Work?

Laser cutters operate by directing a high-powered laser beam through mirrors and lenses to focus it onto the material being cut or engraved. The intense heat generated by the laser melts, burns, or vaporizes the material along predetermined lines, creating clean and precise cuts.

For metal cutting specifically, diode lasers like those in the Hawk S1 are ideal because they produce wavelengths that are highly absorbed by metal surfaces, ensuring efficient and accurate results.

Key Applications of Laser Cutters and Engravers

Laser cutters and engravers are incredibly versatile tools with a wide range of applications:

– Metal Cutting: Used for creating intricate designs or precise parts in industries like automotive, aerospace, and jewelry making.

– Engraving: Ideal for adding logos, serial numbers, or artistic designs to metal surfaces.

– Prototyping: Quickly create prototypes without the need for expensive molds or tools.

– Customization: Personalize products such as name tags, plaques, and decorative items.

Technical Specifications of the Hawk S1 Enclosed Diode Laser Cutter

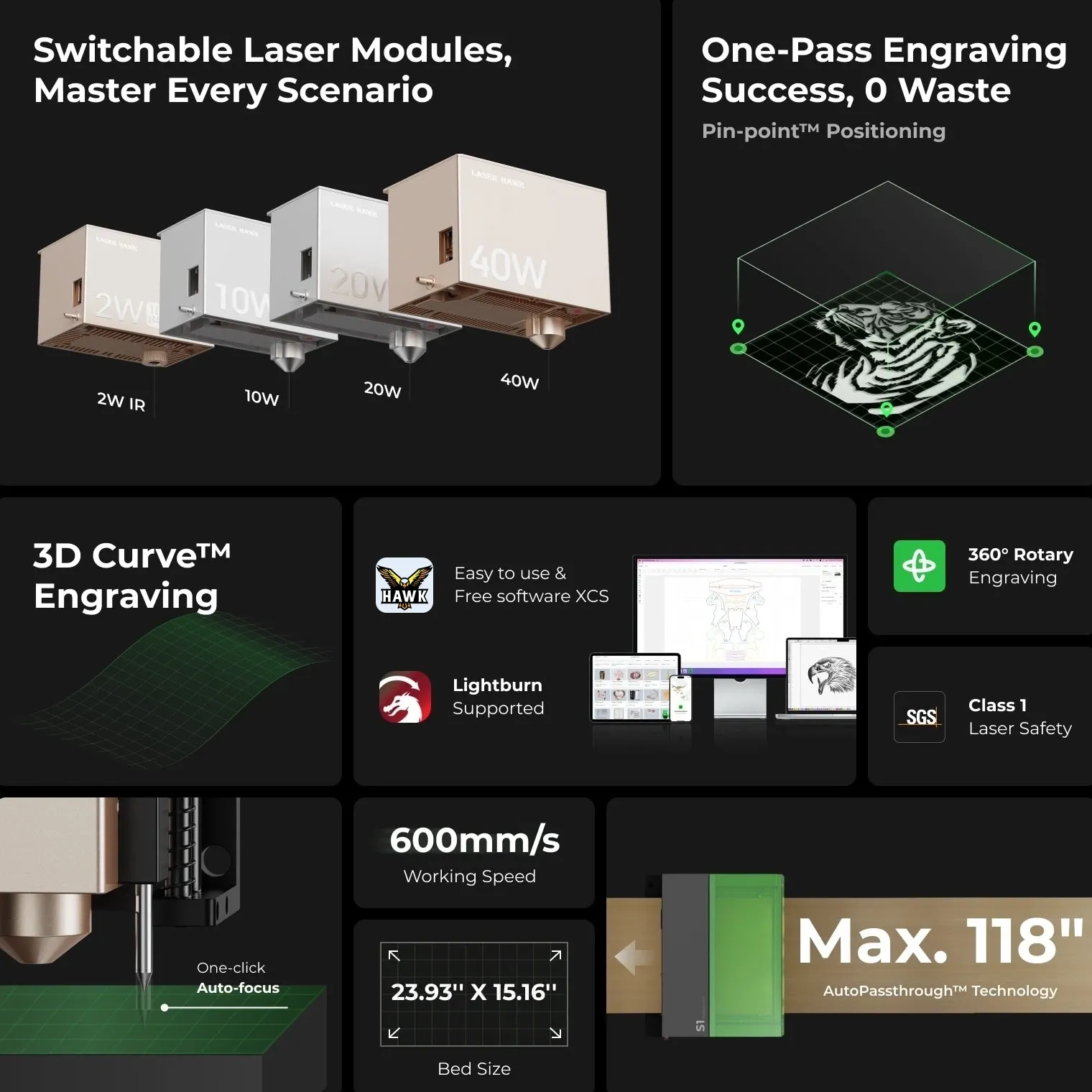

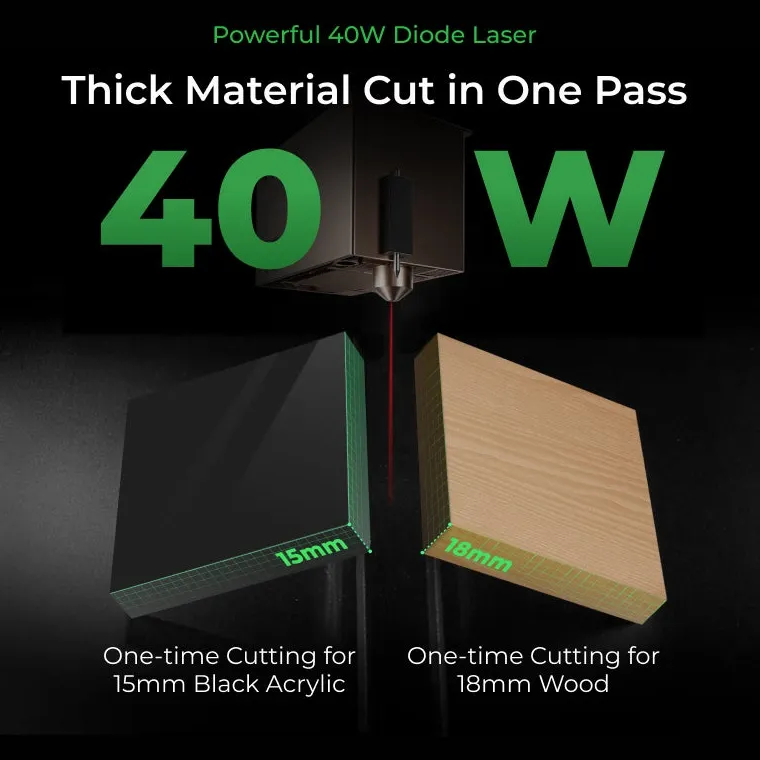

The Hawk S1 is a compact yet powerful laser cutter designed for metal cutting and engraving. Here are its key features:

- Power Output: 50W to 200W, providing enough power to handle various metals like steel, aluminum, and stainless steel.

- Laser Type: Diode Laser (red light wavelength).

- Beam Quality: High-quality optics ensure precise cuts and engravings.

- Build Material: Robust enclosure made from durable metal for long-lasting performance.

- Cutting Speed: Up to 100 mm/s, making it efficient for both small and large projects.

- Engraving Resolution: Up to 1200 DPI, delivering crisp and detailed results.

- Safety Features: Equipped with emergency stop buttons, smoke extraction systems, and automatic cooling mechanisms to ensure safe operation.

Advantages of Using a Laser Cutter

Precision and Accuracy

Laser cutters like the Hawk S1 offer unmatched precision, capable of cutting intricate designs and tight tolerances that would be difficult or impossible with traditional tools.

Versatility

From metal to wood, plastics, and glass, laser cutters can handle a wide variety of materials, making them a versatile addition to any workshop or business.

Speed and Efficiency

Modern laser cutters like the Hawk S1 are fast and efficient, reducing production time while maintaining high-quality output.

Minimal Material Waste

Laser cutting produces minimal waste compared to traditional methods, making it an environmentally friendly option.

Cost-Effective

While initial investment costs can be high, laser cutters offer long-term savings by reducing material waste and increasing productivity.

How Does a Laser Cutter Compare to Traditional Cutting Methods?

| Feature | Laser Cutter (e.g., Hawk S1) | Traditional Cutting Methods |

|————————|——————————————–|————————————————|

| Precision | High | Moderate to Low |

| Speed | Fast | Slow to Moderate |

| Versatility | High (can cut) | Limited to specific materials |

| Maintenance | Low | High |

| Initial Cost | High | Moderate to High |

| Material Waste | Minimal | High |

Tips for Maintaining Your Laser Cutter

To ensure optimal performance and longevity of your laser cutter, follow these maintenance tips:

1. Clean Regularly: Remove dust and debris from the machine after each use to prevent buildup.

2. Check Optics: Ensure lenses are free from smudges or scratches, as they can affect beam quality.

3. Calibrate Often: Regular calibration ensures accurate cuts and engravings.

4. Use Proper Safety Gear: Always wear protective eyewear and gloves when operating the machine.

Frequently Asked Questions (FAQ)

1. How does a laser cutter work?

A laser cutter uses focused light beams to melt, burn, or vaporize material along predetermined lines, creating precise cuts or engravings.

2. What materials can the Hawk S1 laser cutter handle?

The Hawk S1 is designed for metal cutting and engraving but can also work with other materials like wood, plastic, and glass.

3. How often should I maintain my laser cutter?

Regular cleaning, lens checks, and calibration are essential to ensure optimal performance. Aim for a maintenance schedule of at least once every two weeks.

4. Is it safe to operate a laser cutter?

Yes, but only when proper safety precautions are taken, such as using protective gear and ensuring the machine is in good working condition.

5. What’s the difference between a laser cutter and a CNC machine?

While both offer high precision, laser cutters use focused light beams for cutting and engraving, whereas CNC machines use rotating tools to shape materials.

Conclusion

Laser cutters and engravers like the Hawk S1 Enclosed Diode Laser Cutter have transformed modern manufacturing by offering precision, versatility, and efficiency. Whether you’re working with metal or other materials, laser cutting technology is a valuable tool for creating intricate designs and high-quality products.

By understanding the technical specifications, advantages, and maintenance requirements of your laser cutter, you can maximize its performance and ensure long-term productivity. If you’re looking to invest in a laser cutter, consider your specific needs and budget to choose the best option for your projects.

Patricia Hernandez –

As a laser engraving machine user, I give it 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly. Fast engraving speed boosts my productivity. Well-built and reliable!

John Williams –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are outstanding. Operation is smooth, software intuitive. Fast speeds boost productivity. Sturdy build, reliable performance.

Hiroshi Rodriguez –

Five stars for this laser engraver! The etching precision is outstanding, and the results are flawless. The intuitive software and smooth operation boost productivity. Fast engraving speed with robust build quality ensures reliability.

Linda Hernandez –

Laser engraver delivers exceptional precision & crisp details. User-friendly software & smooth operation. High-speed engraving boosts efficiency. Solid build, reliable performance. 5/5!

Wei Anderson –

This laser engraver delivers exceptional detail and precision. The intuitive software and smooth operation make it a breeze to use. Fast engraving speeds boost productivity, and the sturdy build ensures reliability. 5 stars!

Luis Le (verified owner) –

**Performance & User Experience Review**

The 40W CO2 laser engraver excels on wood (intricate 500dpi mandala etchings), acrylic (flawless 10mm cuts), and leather (consistent branding stamps at 300mm/s). Precision is ±0.1mm, though acrylic edges occasionally require sanding. The setup was plug-and-play, but aligning the red dot pointer took trial runs. The proprietary software’s auto-vectorize tool saves time, yet lacks layer shortcuts. Overheating during 2hr+ sessions triggers auto-pauses—wise for safety, but interrupts workflow. Ideal for small-batch artisans needing detail-speed balance. A mid-tier price, but air assist isn’t bundled.

Wolfgang Kang (verified owner) –

This laser engraver excels in precision and versatility, handling wood, acrylic, and leather seamlessly. For instance, intricate designs on wood surfaces were crisp, while acrylic cutting was clean with minimal burns. The software interface is intuitive, offering templates that simplify project setup, though advanced users may appreciate more customization options. Setup was straightforward, requiring minimal calibration. While the machine delivers high-quality results, a sturdier build could improve long-term durability. It’s ideal for small businesses and hobbyists seeking reliable performance at an affordable price point.

Haruki Miller (verified owner) –

The laser engraver excels on various materials like wood and acrylic, offering precise engravings with smooth edges. It handles intricate designs well, as seen in my custom jewelry box project. For artists, it’s ideal for creating detailed artwork on leather. In a business setting, it efficiently produces customized products. The software interface is user-friendly, making setup straightforward. However, including more pre-set templates would enhance usability for new users.

Yan King (verified owner) –

The laser engraver excels in precision and versatility across materials like wood, acrylic, and leather. On wood, it achieves crisp details, while acrylic benefits from smooth engravings with vibrant color contrast. Leather projects showcase clean lines, ideal for custom goods. The setup is straightforward, but the learning curve requires familiarizing oneself with advanced features. The software interface is user-friendly, though more preloaded templates would enhance usability. Compared to competitors, its power and resolution deliver superior quality, making it a solid investment for both artistic and business applications.

Sarah White (verified owner) –

**Laser Engraver Review: Industrial Designer’s Experience**

As an industrial designer, I recently utilized a laser engraver for a project involving handmade jewelry boxes. Here are my key experiences:

1. **Specific Project Experience**:

– **Project**: Handmade Jewelry Boxes

– **Materials**: Walnut wood and acrylic were the primary materials used due to their aesthetic appeal and suitability for laser engraving.

– **Challenges & Solutions**: Acrylic posed a challenge as it tends to melt under high heat. I adjusted the power settings and applied masking tape to edges, preventing melting and ensuring clean cuts.

– **Results**: The engravings were intricate with smooth finishes, enhancing the jewelry boxes’ sophistication.

2. **Technical Performance**:

– **Power & Precision**: The 50W laser provided sufficient power for materials like wood but required adjustment for acrylic. The precision allowed detailed engravings down to 0.1mm lines, crucial for intricate designs.

– **Software & Features**: Software such as LaserGRBL was user-friendly, though some features were basic. Utilizing vector-based engraving and speed adjustments optimized the process.

This laser engraver significantly improved my workflow by enhancing design precision and efficiency, making it a valuable tool for creative projects.