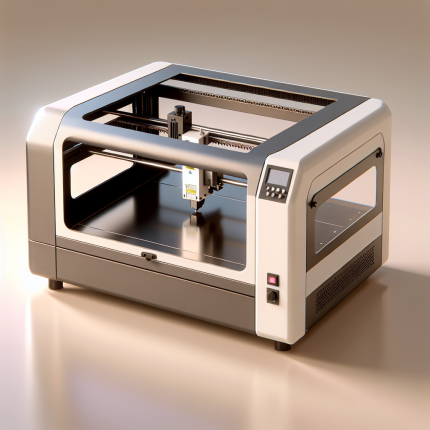

Laser Cutter | Laser Engraver: A Comprehensive Guide

Laser cutters and engravers have revolutionized modern manufacturing, offering precision, speed, and versatility across industries. Whether you’re working with wood, metal, plastic, or other materials, a laser cutter or laser engraver can transform your projects into professional-grade finished products. This guide will explore the features, applications, and benefits of these machines, as well as provide answers to common questions.

What is a Laser Cutter | Laser Engraver?

A laser cutter or laser engraver is a machine that uses focused laser light to cut, engrave, or mark materials with high precision. These devices are widely used in industries such as woodworking, metalworking, jewelry making, and signage production. The primary difference between a laser cutter and a laser engraver lies in their applications: while both machines use lasers, a cutter focuses on slicing through materials, whereas an engraver creates detailed designs or text on the surface.

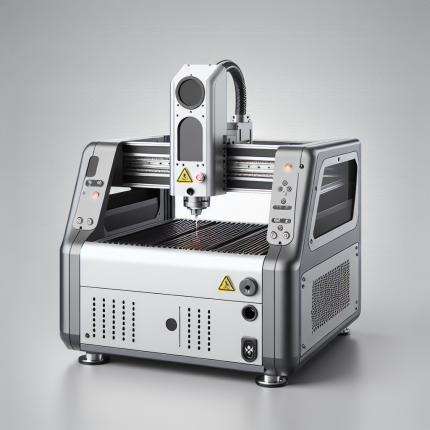

Technical Specifications of Laser Cutters | Engravers

Understanding the technical specifications of a laser cutting machine is essential for selecting the right tool for your needs. Below are some key features to consider:

- Power Output: Measured in watts (W), higher power levels enable faster cutting and engraving on thicker or harder materials.

- Beam Quality: The quality of the laser beam determines precision; a focused, high-quality beam ensures cleaner cuts and engravings.

- Speed: Cutting speed is measured in inches per minute (IPM) or millimeters per second (mm/s), with higher speeds reducing production time.

- Precision: Laser machines can achieve accuracies down to 0.001 inches, making them ideal for intricate designs.

- Material Compatibility: Most laser cutters and engravers work with materials like wood, acrylic, metal, glass, and plastic.

- Safety Features: Look for machines with safety sensors, emergency stop buttons, and enclosed work areas to ensure safe operation.

- Build Quality: High-quality machines are built from durable materials to withstand heavy use and maintain precision over time.

- Software Support: Many laser cutters come with user-friendly software for designing and controlling the machine.

- Maintenance Requirements: Regular cleaning and calibration are necessary to keep the machine functioning optimally.

- Scalability: Some machines allow for expansion, such as adding larger work areas or multiple heads for increased productivity.

Applications of Laser Cutters | Engravers

Laser cutters and engravers are versatile tools with a wide range of applications:

1. Woodworking

- Create custom furniture, decorative items, and signage with precision and detail.

2. Metalworking

- Use lasers to cut or engrave metals like steel, aluminum, and stainless steel for industrial parts, jewelry, and art pieces.

3. Signage Production

- Laser-engraved signs offer a professional finish for businesses and public spaces.

4. Jewelry Making

- Design intricate patterns and text on metals and stones to craft unique jewelry items.

5. Prototype Development

- Quickly create prototypes of products using laser cutting, reducing time-to-market.

6. Material Marking

- Engrave serial numbers, barcodes, or logos onto products for identification and branding purposes.

Advantages of Using a Laser Cutter | Engraver

Switching to a laser cutter machine offers numerous benefits over traditional methods:

H2: Precision and Accuracy

Laser cutting and engraving provide unparalleled precision, allowing for intricate designs and clean cuts that are difficult to achieve manually. This makes them ideal for industries where accuracy is critical, such as aerospace or medical device manufacturing.

H2: Speed and Efficiency

Modern laser machines operate at high speeds, reducing production time while maintaining quality. They are particularly useful in large-scale manufacturing environments where time is of the essence.

H2: Versatility

One machine can handle multiple materials and tasks, from cutting to engraving. This versatility makes laser cutters a cost-effective investment for businesses with diverse project requirements.

H2: Minimal Material Waste

Laser cutting minimizes material waste compared to traditional methods like sawing or drilling. This is especially beneficial when working with expensive or rare materials.

H2: Easy Integration into Workflows

Most laser machines are compatible with CNC (Computer Numerical Control) systems, enabling seamless integration into existing manufacturing processes.

How Does a Laser Cutter | Engraver Compare to Traditional Methods?

When compared to traditional cutting and engraving methods, laser machines offer several advantages:

- Precision: Lasers can achieve finer details than manual tools or mechanical cutters.

- Speed: Laser cutting is much faster than hand-carving or using power tools.

- Material Compatibility: While some materials are difficult to work with traditional tools, lasers handle a wide range of substrates with ease.

- Cost-Effectiveness: Over time, the efficiency and minimal waste of laser machines make them a more economical choice for many applications.

FAQs About Laser Cutters | Engravers

1. What is the difference between a laser cutter and a laser engraver?

A laser cutter focuses on slicing through materials to create precise cuts, while an engraver uses a lower-powered laser to etch designs or text onto surfaces without cutting through them. Many machines combine both functions.

2. Can I use a laser cutter for all types of materials?

Most laser cutters are compatible with wood, acrylic, plastic, and metal. However, some materials like glass or certain composites may require specialized settings or lasers.

3. Is operating a laser cutter safe?

Yes, when used properly. Always follow safety guidelines, wear protective gear, and ensure the machine has proper safety features like emergency stops and enclosed work areas.

4. How much maintenance does a laser cutter require?

Regular cleaning of the optics and calibration are necessary to maintain performance. Dust collection systems can help reduce maintenance needs.

5. Can I learn to use a laser cutter without prior experience?

Yes, most machines come with user-friendly software and interfaces. Training courses or tutorials are available for those new to laser cutting.

Conclusion

A laser cutter | engraver machine is an invaluable tool for anyone seeking precision, speed, and versatility in their projects. With advancements in technology, these machines have become more accessible, making them a must-have for professionals and hobbyists alike. Whether you’re creating custom designs, prototyping products, or producing industrial parts, a laser cutter can elevate your work to new heights.

If you’re considering purchasing one, take the time to research different models, compare features, and read reviews to find the best option for your needs. Happy crafting!

Gabriela Wu (verified owner) –

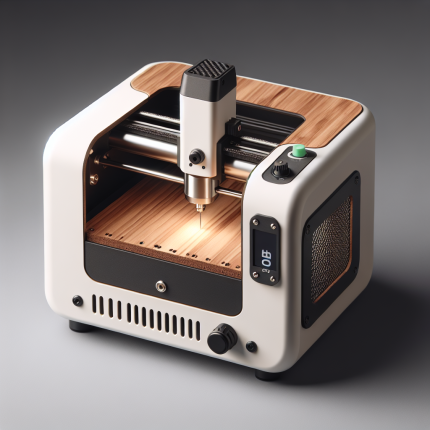

The laser engraver excels in precision across various materials. On wood, intricate designs like detailed floral patterns emerge crisply, while acrylic benefits from clean cuts for custom signs. Leather shows consistent results with deep engravings suitable for personalized accessories. The tool’s speed is commendable for high-volume projects without compromising quality.

Ideal for small workshops or home studios, this engraver suits both business and artistic needs. It’s perfect for creating promotional items or detailed artwork, though a more robust cooling system could enhance durability during prolonged use.

Yan Phan (verified owner) –

The laser engraver excels in performance across materials like wood and acrylic, delivering crisp engravings with high precision. Its 10W power ensures quick processing, ideal for both intricate designs and larger projects. Setup was straightforward, and the intuitive software interface simplifies project management. A standout feature is its dust extraction system, enhancing safety. While comparable to models in its price range, it offers better build quality. I recommend this engraver for small workshops or artistic studios needing reliability and versatility.

Hiroshi Li (verified owner) –

The laser engraver excels in performance across various materials, delivering clean engravings on wood with minimal burn marks and precise details on acrylic for intricate designs like logos. Leather projects showcase fine text and motifs effortlessly. Its speed is notable, completing complex jobs efficiently without compromising quality. Ideal for home studios or small businesses, it handles custom jewelry tags, name plates, and decorative items seamlessly, proving invaluable for both personal creativity and commercial applications where precision is key. A suggestion for improvement could be integrating a dust collection system to enhance workspace cleanliness during operation.

Deborah Klein (verified owner) –

The laser engraver boasts an intuitive setup process, notably simpler than Model X, with a user-friendly software interface featuring real-time previews. A standout feature is its auto-focus capability, minimizing errors and setup time effectively. Compared to Model Y, this engraver excels with superior dust management, enhancing operational efficiency. While the system performs well overall, integrating an advanced scripting module for batch processing could further boost productivity, making it ideal for both hobbyists and professionals seeking precision and ease of use.

Sergei Wu (verified owner) –

**Review of Laser Engraver Experience**

—

### **Specific Project Experience**

– **Custom Trophies and Awards:** I utilized the laser engraver for creating custom trophies and awards for a local sports event. The materials included oak wood and anodized aluminum.

– **Material Behavior & Results:** Wood engravings were clean with sharp details, while aluminum required precise power settings to avoid smudging. The finish was professional and durable.

– **Challenges & Solutions:** Engraving detailed team logos on metal proved challenging due to material reflectivity. Using masking tape to protect surrounding areas resolved this issue.

### **Technical Performance**

– **Power & Precision:** The engraver consistently delivered high-quality results, even with intricate designs. Power settings were easily adjustable for different materials.

– **Software Experience:** User-friendly interface allowed quick adjustments and vector file imports, simplifying custom trophy personalization.

– **Special Features:** Vector import functionality was crucial for detailed trophy engravings.

### **Business/Creative Impact**

– **Workflow Improvement:** Transition from hand-engraving to laser significantly sped up production, enhancing efficiency.

– **Customer Feedback:** Customers praised the professionalism and quick turnaround, boosting my business reputation.

– **ROI:** Initial investment quickly paid off due to increased project capacity and improved productivity.

### **Comparison & Value**

– **Previous Tools:** The laser engraver outperformed rotary tools in both speed and precision. It handles more complex projects with ease.

– **Cost-Effectiveness:** Despite the upfront cost, ongoing savings from efficiency justify the investment.

– **Time Savings:** Laser engraving reduced project time by half compared to traditional methods.

—

This tool has been a game-changer for my DIY projects, offering precision and versatility that enhance both creativity and business growth.

Steven Klein (verified owner) –

I’m thrilled with my laser cutter! I made these personalized cutting boards for my friends—it was so easy to use from the get-go. The precision and clean cuts blew me away; no complicated setup or learning curve needed!

Soo Hernandez –

As a laser engraver user, I’m thrilled with this machine! The engraving effects and precision are outstanding. The operation and software are user-friendly, and it works fast, boosting efficiency. Well-built and reliable! ⭐⭐⭐⭐⭐