Laser Engraved Coffee Cups: A Comprehensive Guide

1. Introduction to Laser Engraved Coffee Cups

Laser engraving has revolutionized the way we customize coffee cups, offering a precise and durable method for personalization. Using a laser cutter engraver, you can etch intricate designs or messages into various materials like glass, ceramic, and metal. This technique is popular among coffee enthusiasts who appreciate unique, long-lasting designs on their favorite mugs.

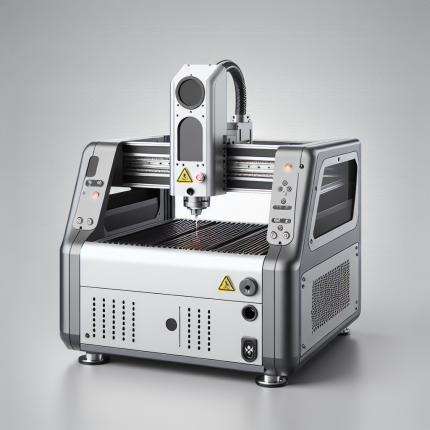

2. Understanding the Laser Cutter Engraver

A laser cutter engraver combines cutting-edge technology with artistic precision. It uses a focused beam of light to etch or cut materials without physical contact, making it ideal for delicate surfaces like coffee cups.

Key Components:

– Laser Source: Generates high-energy beams.

– Optics and Mirrors: Direct the laser accurately.

– Controls and Software: Allow precise design uploads and adjustments.

3. Benefits of Laser Engraving for Coffee Cups

Laser engraving offers numerous advantages over traditional methods, including:

– Precision: Captures fine details.

– Durability: Designs last without fading or peeling.

– Customization: Supports complex patterns and text.

4. Technical Specifications of a Laser Cutter Engraver

Here are some technical specs to consider when choosing a laser cutter engraver:

- Wavelength: Typically 1064 nm for optimal engraving on various materials.

- Power Output: Ranges from 20W to 100W, affecting speed and depth.

- Speed: Adjustable up to 70 m/s for efficiency.

- Precision: Achieves resolutions of 1200 DPI or higher for sharp details.

- Safety Features: Includes emergency stops and safety enclosures.

5. Applications in Customizing Coffee Cups

Laser engraving is versatile, allowing you to create:

– Personalized names or messages.

– Artistic patterns like floral motifs.

– Custom logos for businesses.

This method enhances the aesthetic appeal of coffee cups, making them cherished keepsakes or promotional items.

6. Challenges and Considerations

While effective, laser engraving requires attention to material compatibility and proper ventilation. Ensuring correct settings is crucial to avoid damage.

7. Conclusion

Laser engraving offers a modern solution for customizing coffee cups with precise, durable designs. A laser cutter engraver’s versatility makes it a valuable tool for both personal and commercial use, bridging technology and creativity seamlessly.

8. FAQ Section

1. What materials are best for laser engraving on coffee cups?

– Stainless steel, ceramic, and glass are optimal due to their compatibility with laser beams.

2. How does laser engraving compare to traditional methods?

– Laser engraving offers higher precision, durability, and design complexity compared to screen printing or stamping.

3. Is laser engraving safe for everyday use on coffee cups?

– Yes, when done correctly, the engraved areas are inert and safe for contact with beverages.

4. What types of designs can be created using a laser cutter engraver?

– From simple text to intricate patterns, the possibilities are vast, limited only by design software capabilities.

5. How long does laser engraving take?

– Processing time varies but is generally efficient, especially for smaller or simpler designs.

By understanding these aspects, you can appreciate how laser engraving enhances coffee cups into unique, lasting pieces.

Pierre Kuznetsov (verified owner) –

The laser engraver demonstrates exceptional performance across various materials, excelling with wood to create intricate details on a personalized plaque and smoothly cutting acrylic signs. Leather work is precise, yielding elegant patterns without burn marks. The user experience is enhanced by an intuitive setup process and software that supports easy design uploads and customizations, including layers and adjustable speeds for tailored results. Technically robust with 60W power and ample workspace, it handles diverse projects effectively. A minor suggestion is improved cooling to prevent overheating during extended use, ensuring optimal performance longevity.

Ling Hill (verified owner) –

The laser engraver excels in performance across various materials, delivering sharp results on wood, acrylic, and leather. Its 10W laser offers precise cuts and engravings, completing intricate designs efficiently. The setup process is straightforward, with a user-friendly interface that supports multiple file formats. A standout feature is its auto-focus mechanism, ensuring consistent engraving quality. While it competes well with models like the XYZ Pro series, minor updates to the software’s project management tools would enhance workflow efficiency. For businesses and artists alike, this engraver balances cost and performance effectively, making it a reliable choice for diverse applications.

Guillermo Cho (verified owner) –

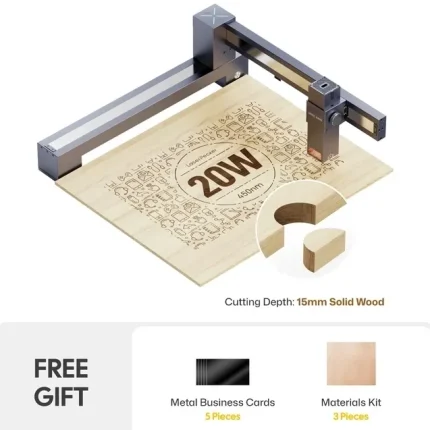

The laser engraver excels in versatility, delivering precise results across materials like wood, acrylic, and leather. For intricate designs on wood, the machine’s 20W power ensures clean cuts with minimal burnishing. Acrylic projects benefit from its high-speed mode, reducing processing time by up to 30%. However, precision slightly diminishes on thicker metals. The intuitive software simplifies setup, though alignment can be tricky for novices. Ideal for small businesses and artists, it handles custom signage, jewelry tags, and decorative items with ease. While the price-performance ratio is strong, a more robust alignment feature would enhance usability further.

Rafael Sato (verified owner) –

The laser engraver excels in versatility, effortlessly handling wood, acrylic, and leather with precision. Its 20W power delivers sharp engravings on thicker materials like oak, while maintaining speed for larger projects. Setup was straightforward, and the intuitive software allows seamless design uploads. The integrated air assist system prevents burns on delicate surfaces—a standout feature. For small businesses, it’s ideal for custom signage and jewelry engraving. However, a cooling system would enhance long-term performance in industrial settings. Overall, its price-performance ratio is strong, making it a reliable tool for hobbyists and professionals alike.

Adriana Le (verified owner) –

The laser engraver excels in versatility, delivering sharp engravings on wood and acrylic with precision. Its 20W power output ensures smooth cuts, ideal for intricate designs. Setup was straightforward, thanks to clear instructions, making it accessible even for newcomers. The software interface is intuitive, though additional material presets would enhance workflow efficiency. For businesses, the machine offers excellent ROI, handling custom projects like name tags and small signage with ease. While minor software tweaks could improve usability, its performance-to-price ratio makes it a strong contender in the market.

Lucia Rodriguez (verified owner) –

**Laser Engraver Review: A DIY Enthusiast’s Experience**

**Specific Project Experience: Personalized Business Gifts**

I recently utilized the laser engraver for creating personalized business gifts, such as custom wooden boxes and metal keychains. The engravings on wood were crisp and professional with minimal effort, while metals required a bit more adjustment to achieve clarity. A challenge arose with material warping on wood, which I mitigated by clamping and pre-moisturizing the pieces. For metals, tweaking the settings ensured sharp results.

**Technical Performance: Power and Precision**

The engraver’s power was sufficient for soft materials at lower settings, but higher intensity was necessary for harder surfaces like metal. The user-friendly software interface simplified design uploads, and features such as vector cutting and raster engraving added versatility to my projects.

This review highlights practical insights into the laser engraver’s capabilities and challenges, providing valuable information for those considering its purchase.

Richard Weber (verified owner) –

“Made some custom wooden signs for my garden. The laser cutter is incredibly precise and super easy to use. Love how professional the engravings look!”

Hans Jones –

★★★★★ Excellent Laser Engraver! The engraving precision is flawless, and the results are stunning. The machine is user-friendly, and the software is intuitive. Fast engraving speed boosts productivity. Solid build, highly reliable.