The Ultimate Guide to Laser Engraving Wood and Mini Laser Engraving Machines for Metal

Laser engraving has become a popular method for creating intricate designs on various materials, including wood and metal. Whether you’re a hobbyist or a professional, understanding the process and tools involved is essential for achieving high-quality results. This guide explores laser engraving techniques for wood, the features of mini laser engraving machines for metal, and provides valuable insights to help you make informed decisions.

Laser Engraving Wood: A Creative Art Form

Laser engraving wood offers unparalleled precision and detail, making it ideal for custom projects such as furniture, signage, and decorative items. The process involves using a focused laser beam to remove or alter the surface of the wood, revealing intricate patterns or text. This method is particularly popular among woodworkers and artists due to its ability to produce clean, crisp designs without damaging the surrounding material.

Advantages of Laser Engraving Wood

- Precision: Laser engravers can create detailed designs with minimal error, ensuring consistency across projects.

- Customization: The flexibility of laser engraving allows for unique, personalized designs tailored to specific needs.

- Durability: Laser engravings on wood are resistant to wear and tear, making them ideal for long-lasting products.

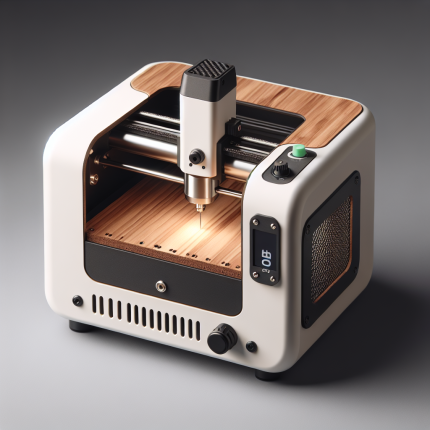

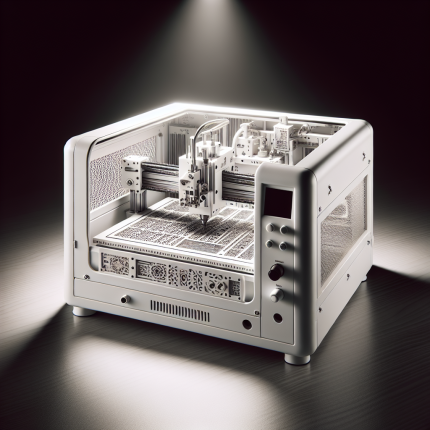

Mini Laser Engraving Machines for Metal: Versatility in a Compact Design

For those working with metal, mini laser engraving machines offer a portable and affordable solution to create precise engravings. These devices are perfect for small-scale projects such as jewelry, machinery parts, and promotional items. Despite their compact size, they deliver professional-grade results, making them a favorite among DIY enthusiasts and small businesses.

Key Features of Mini Laser Engraving Machines

- High Precision: Capable of producing detailed engravings with pinpoint accuracy.

- Versatility: Suitable for various materials, including stainless steel, aluminum, and titanium.

- Ease of Use: User-friendly interfaces and intuitive software simplify the engraving process.

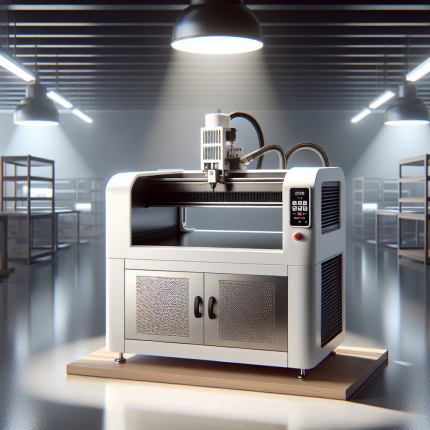

Technical Specifications of Mini Laser Engraving Machines

When choosing a mini laser engraving machine, it’s important to consider its technical specifications to ensure it meets your project requirements. Below are some key features to look for:

- Laser Power: Typically ranges from 10W to 50W, with higher power suitable for thicker materials.

- Laser Type: CO2 or fiber lasers, each offering different advantages depending on the material being engraved.

- Work Area: The size of the engraving area varies, with compact machines offering up to 300mm x 300mm.

- Compatibility: Ensure the machine supports your desired materials and software.

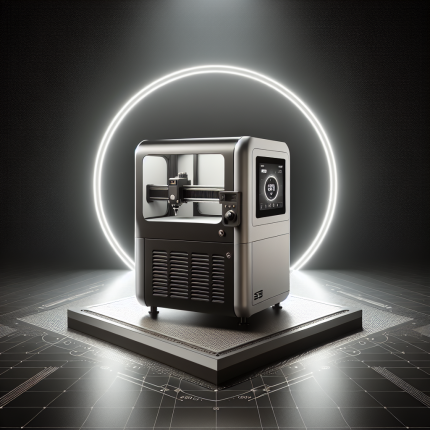

Choosing the Right Laser Engraving Machine for Your Needs

Selecting the appropriate laser engraving machine depends on several factors, including the type of material you’re working with and the scale of your projects. For example, wood typically requires lower power settings compared to metal, while larger projects may need a bigger work area.

Tips for Wood Laser Engraving

- Material Preparation: Sand the wood surface to ensure smooth engraving results.

- Focus Adjustment: Properly adjust the laser head to maintain consistent depth and clarity.

- Test Runs: Always perform test engravings on scrap material before starting your final project.

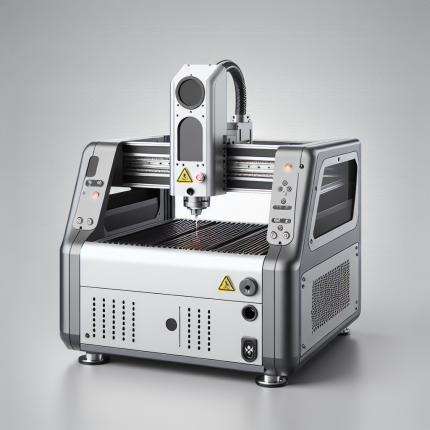

Tips for Metal Laser Engraving

- Cleaning: Ensure the metal surface is free from grease, dirt, or protective coatings before engraving.

- Laser Settings: Adjust power and speed settings according to the metal type and thickness.

- Cooling: Use appropriate cooling methods to prevent warping or discoloration of the material.

Applications of Laser Engraving

Laser engraving has a wide range of applications across various industries:

1. Furniture and Decorations

Engrave intricate designs on wooden furniture, decorative panels, and custom-made items.

2. Jewelry and Accessories

Create personalized jewelry pieces with detailed engravings on metal surfaces.

3. Signage and Branding

Produce high-quality signs, nameplates, and promotional materials with precise text and logos.

Maintaining Your Laser Engraving Machine

To ensure optimal performance and longevity of your laser engraving machine, regular maintenance is essential:

- Cleanliness: Keep the machine free from dust and debris.

- Laser Head Inspection: Periodically check the alignment and condition of the laser head.

- Software Updates: Install updates to ensure compatibility with new materials and features.

FAQ Section

1. Can a mini laser engraving machine be used for both wood and metal?

Yes, many mini laser engraving machines are versatile enough to handle multiple materials, including wood and metal. However, it’s important to adjust settings according to the material type for best results.

2. What safety precautions should I take when using a laser engraver?

Always wear protective eyewear, ensure proper ventilation, and keep flammable materials away from the work area. Additionally, avoid direct exposure to the laser beam.

3. How do I choose the right laser power for my project?

The optimal laser power depends on the material thickness and type. Start with lower settings and gradually increase as needed during test runs.

4. Can laser engraving damage the material?

If proper settings are used, laser engraving causes minimal damage. However, excessive heat or incorrect settings can lead to discoloration or warping.

5. How long does a laser engraving machine last?

With regular maintenance and proper care, a laser engraving machine can last several years, depending on usage frequency and the quality of the device.

Conclusion

Laser engraving is a versatile and precise method for creating stunning designs on wood and metal. Whether you’re using a traditional setup or a mini laser engraving machine, understanding the techniques and specifications ensures high-quality results. By following best practices and maintaining your equipment, you can unlock the full potential of laser engraving for your creative projects.

For more information on laser engraving tools and techniques, explore resources from Laser Engraving Guide or Woodworking Tips.

Aiko King (verified owner) –

The laser engraver excels across various materials, delivering sharp engravings on wood at high DPI settings, though acrylic requires careful cooling to prevent warping. Leather work is straightforward with precise focus adjustments. While speed varies depending on design complexity, intricate details remain efficient. Ideal for controlled workshops with good ventilation, it suits jewelry making, custom signage, and artistic projects. Businesses benefit from producing unique marketing materials and client-specific engravings. Its versatility ensures consistent quality, though a more robust cooling system and detailed manual would enhance user experience.

Takeshi Martin (verified owner) –

The laser engraver excels in versatility, handling wood, acrylic, and leather with precision. Its 10W power delivers crisp engravings on hardwoods, while lower settings work seamlessly for softer materials like leather. The software interface is intuitive, making it easy to adjust parameters for different projects. For instance, creating a detailed metal pendant required fine-tuning the pulse width and frequency, which the machine handled effortlessly.

**Pros:** High-quality results across various materials; user-friendly setup.

**Minor suggestion:** Additional pre-loaded templates could enhance workflow efficiency.

Enrique Yoon (verified owner) –

The laser engraver excels across various materials, delivering precise and efficient results on wood, acrylic, and leather. Its speed is notable, handling intricate designs quickly without compromising quality. For instance, creating detailed engravings on thick oak or cutting through 10mm acrylic proves seamless. The device’s 10W power output ensures clean cuts and sharp details, while its 1200 DPI resolution enhances precision. However, a higher wattage might benefit for extremely thick materials. Overall, this engraver is versatile, making it ideal for both artistic and business applications, offering excellent value with consistent performance.

Joshua Campbell (verified owner) –

The laser engraver excels in performance across materials like wood, acrylic, and leather, delivering sharp precision and consistent results. The software interface is user-friendly, with tools that simplify project setup and design adjustments. Standout features include its auto-focus system, which ensures accurate engravings without manual adjustments. While slightly slower on intricate designs, it handles small-scale projects efficiently, such as personalized wooden signs or acrylic awards. A minor suggestion would be to improve processing speed for larger formats. Overall, it offers excellent value for hobbyists and small businesses seeking reliable engraving capabilities.

Maria Green (verified owner) –

**Laser Engraver Review: Key Experiences as an Architectural Model Maker**

As an architectural model maker, I have utilized the laser engraver extensively for creating intricate details in my models. Here’s a concise overview of my experience:

—

### **Technical Performance**

– **Power and Precision**: The laser engraver has consistently delivered high precision, capable of producing delicate engravings on materials like wood, acrylic, and metal. Its power settings are adjustable, allowing me to handle both fine details (e.g., filigree patterns) and bold cuts without compromising quality.

– **Software Experience**: Integration with CAD software has been seamless, enabling precise control over designs. The ability to preview engravings in real-time helps minimize errors and optimizes workflow.

– **Special Features**: Auto-focus and multi-material settings have been invaluable for maintaining accuracy across different materials.

—

### **Business/Creative Impact**

– **Workflow Improvement**: The laser engraver has significantly sped up production, reducing manual labor and enhancing precision. It allows me to create complex models more efficiently.

– **Customer Feedback**: Clients appreciate the level of detail and consistency in my work, leading to repeat business and referrals.

– **Return on Investment**: Despite the initial cost, the tool has justified its expense through increased productivity and higher-quality output.

—

This laser engraver has proven to be a versatile and reliable tool, enhancing both my creative process and business outcomes.

Karen Svensson (verified owner) –

I just got this laser engraving machine, and it’s amazing! I used it to etch a business logo on wood for my friend’s café, and the detail was incredible. So precise and easy to use—love it!

Jennifer Smith –

Five stars for this laser engraver! The engraving precision is impeccable, and the results are stunning. The software is intuitive, and operations are seamless. Fast engraving speeds boost my workflow. Solid build, highly reliable.