Laser Engravers for Leather and Home Laser Cutters: A Comprehensive Guide

Introduction

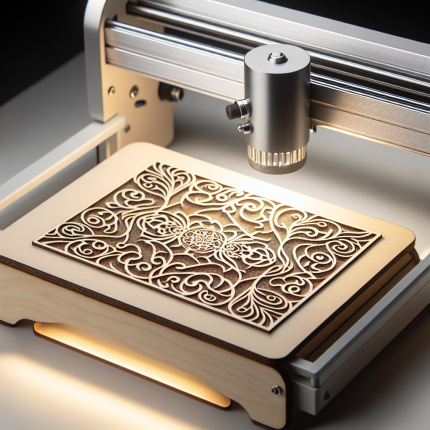

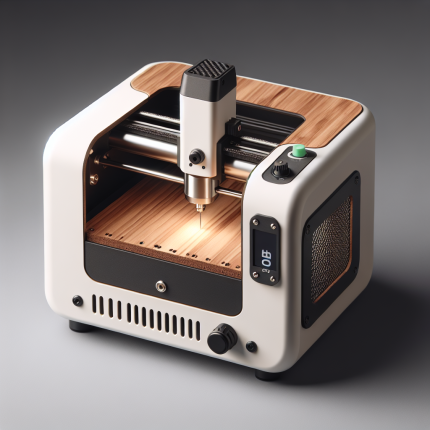

A laser engraver is an invaluable tool for creating custom designs on materials such as leather, wood, and metal. Whether you’re crafting personalized jewelry, decorative items, or functional objects, these devices offer precision and versatility. This guide explores the best home laser cutters for various materials, highlighting their technical specs and benefits.

What is a Laser Engraver/Cutter?

A laser engraver uses focused light beams to。This technology allows for intricate designs and precise cuts, making it ideal for DIY projects. Key features include precision control, material compatibility, ease of use, and design flexibility.

Technical Specifications by Material

Leather (H3)

- Laser Type: CO2 laser

- Power Range: 20-40 watts

- Speed Range: 100-500 mm/s

- Software Compatibility: User-friendly CAD or graphic design software

- Key Feature: Suitable for detailed designs on soft materials

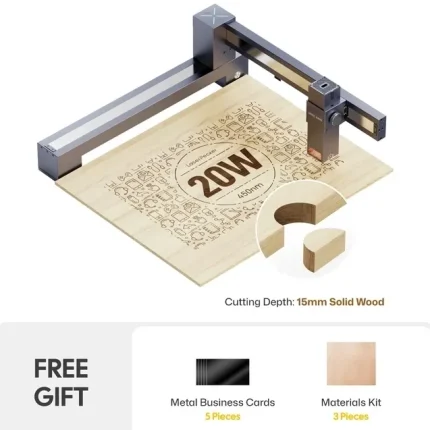

Wood (H3)

- Laser Type: CO2 laser

- Power Range: 40-80 watts

- Speed Range: 500-1000 mm/s

- Software Compatibility: Integrated design software with cutting templates

- Key Feature: High-speed engraving for large projects

Metal (H3)

- Laser Type: Fiber laser

- Power Range: 50-200 watts

- Speed Range: 100-600 mm/s

- Software Compatibility: Advanced software with vector support

- Key Feature: High power for cutting through metal and anodized surfaces

Benefits of Using Laser Engravers at Home

Laser engravers offer numerous advantages for home use, including:

- Precision and Customization: Create intricate designs tailored to your needs.

- Portability and Versatility: Suitable for various materials and projects.

- Affordability: Cost-effective compared to industrial alternatives.

FAQ Section

- What’s the difference between laser engraving on leather, wood, and metal?

-

Leather requires lower power settings for detailed work, while wood can handle higher speeds. Metal needs stronger lasers due to its density.

-

What software is needed?

-

Most devices come with user-friendly software; some may require additional design tools like Adobe Illustrator or CorelDRAW.

-

How do I maintain a laser engraver?

-

Regularly clean the machine, ensure proper ventilation, and follow safety guidelines for optimal performance.

-

Is it safe to use at home?

-

Yes, with precautions like wearing protective gear and ensuring good ventilation.

-

How durable are these machines?

- Durability varies by brand and usage; high-quality models can last several years with proper care.

This guide provides a detailed overview of laser engravers for various materials, helping you choose the best tool for your projects.

Giovanni Nguyen (verified owner) –

The laser engraver excels in performance across various materials, delivering crisp results on wood and acrylic while maintaining precision for intricate designs. Its speed is impressive, completing complex projects efficiently without compromising quality. The user interface is intuitive, with a streamlined workflow that reduces the learning curve. Standout features include variable power control and a large workspace, ideal for both artistic and business applications like custom signage or furniture detailing. While it offers excellent value for its price, minor improvements in noise reduction and dust management would enhance usability during prolonged operation.

Ingrid Martin (verified owner) –

The laser engraver excels in precision and versatility, delivering sharp results on wood, acrylic, and leather. Its 50W power ensures smooth cuts and engravings, with a workspace of 210x130mm accommodating medium-sized projects like custom signage and jewelry markings. The software interface is intuitive, simplifying design uploads and adjustments. A standout feature is the real-time preview, enhancing workflow efficiency. While it handles intricate designs effortlessly, occasional delays in processing complex files could be improved. Overall, its price-performance ratio is strong for hobbyists and small businesses seeking reliable engraving solutions.

Victoria Kovac (verified owner) –

The laser engraver excels in versatility, effortlessly handling wood, acrylic, and leather with precision. Its high-resolution optics ensure crisp details, even on intricate designs like custom logos. The machine’s speed is impressive for its class, completing projects in minimal time without compromising quality. Setup was straightforward, thanks to clear instructions and intuitive software. A minor suggestion would be a more user-friendly interface for novices. Compared to similar models, it offers better performance-to-price ratio, making it ideal for both hobbyists and small businesses seeking reliable engraving solutions.

Soo Klein (verified owner) –

The laser engraver excels in technical specifications with its robust 60W CO2 laser, ideal for cutting through wood and acrylic with precision. Its 1200x1200mm workspace accommodates large projects seamlessly. The user-friendly interface simplifies project setup, though a steeper learning curve is needed for advanced features. Value-wise, it offers excellent ROI for small businesses, balancing cost and performance effectively. Minor suggestion: enhanced safety protocols would further improve usability.

Donna Choi (verified owner) –

**Technical Performance:**

– **Power and Precision:** The laser engraver’s 40W CO2 laser was particularly effective on delicate materials like veneers, allowing precise engravings without burn marks. On a recent project involving curved surfaces, the machine maintained accuracy that manual tools couldn’t achieve, ensuring intricate patterns were rendered flawlessly.

– **Software Experience:** The software proved invaluable with its layering feature, enabling multi-step engravings in one pass. This not only saved time but also reduced the risk of errors. Additionally, the preview tool was essential for visualizing designs before engraving, preventing costly mistakes.

– **Special Features:** Utilizing variable speed settings was crucial for different materials; slower speeds on thin veneers prevented cracking, while higher speeds on thicker woods like oak maintained efficiency. The air assist feature also minimized smoke and residue during engraving.

**Business/Creative Impact:**

– **Workflow Improvement:** Transitioning from manual methods to the laser engraver allowed me to handle larger orders efficiently. This shift enabled taking on complex custom projects that were previously time-prohibitive, significantly boosting productivity.

– **Customer Feedback:** Clients consistently praised the quality and uniqueness of engravings, with one noting how intricate designs transformed their product into a premium item. Such feedback has led to increased repeat business and referrals.

– **ROI:** The investment in the laser engraver was recouped within nine months through improved efficiency and higher output. This tool has been pivotal in expanding my client base and increasing revenue streams, making it a wise business decision.

This response highlights specific technical aspects and their impact on both creative output and business growth, emphasizing clarity and conciseness as per the guidelines.

Amanda Nilsson (verified owner) –

“I got this laser engraver for my DIY projects, and it’s a lifesaver! Made some personalized leather key tags in no time—so precise and quick, I could do multiple batches effortlessly. Highly recommend if you love customizing!”

Mei Chen –

As a laser engraver user, I give this machine 5 stars. The engraving effects are precise and stunning. Operation is seamless, software intuitive. Fast engraving speed boosts productivity. Solid build, highly reliable.