Laser Engraver Machine: A Comprehensive Guide to the LaserHawk LH3 Fiber Laser Engraver

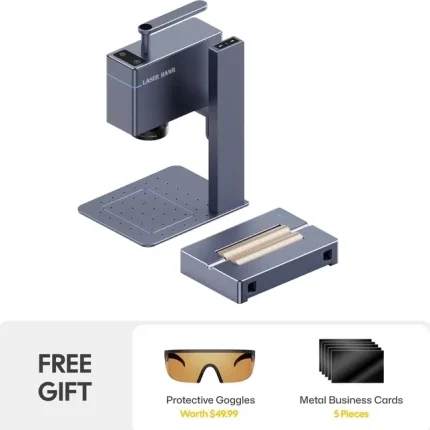

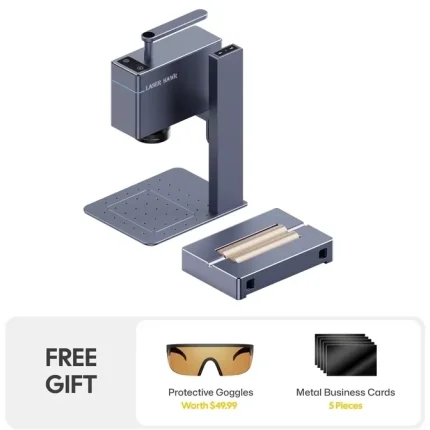

The LaserHawk LH3 is a cutting-edge fiber laser engraver designed for precision and efficiency in industrial and commercial applications. This advanced machine is ideal for those seeking high-quality laser engraving for metal, offering unparalleled performance, durability, and versatility. In this guide, we’ll explore the technical specifications, advantages, and applications of the LaserHawk LH3, as well as provide answers to frequently asked questions about laser engraver machines.

Technical Specifications of the LaserHawk LH3

The LaserHawk LH3 is built with state-of-the-art technology, making it a top choice for professionals in various industries. Below are its key technical specifications:

- Laser Type: Fiber laser

- Wavelength: 1064 nm

- Power Output: Up to 2000 watts (adjustable)

- Marking Speed: Up to 70 meters per second

- Engraving Area: Up to 1500mm x 1500mm

- Precision: ±0.01 mm accuracy

- Cooling System: Integrated liquid cooling system for optimal performance

- Control Interface: User-friendly CNC control panel with intuitive software

These specifications make the LaserHawk LH3 suitable for a wide range of applications, including metal engraving, cutting, and marking on various materials such as stainless steel, aluminum, titanium, and more.

Advantages of the LaserHawk LH3 Fiber Laser Engraver

The LaserHawk LH3 stands out in the market due to its numerous advantages:

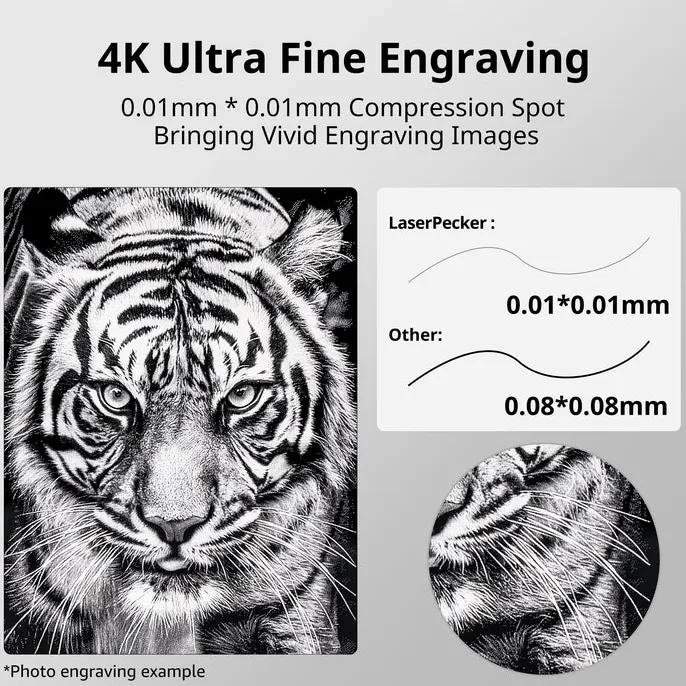

1. High Precision and Accuracy

With a precision of ±0.01 mm, the LaserHawk LH3 ensures intricate details are engraved with exceptional accuracy, making it ideal for complex designs.

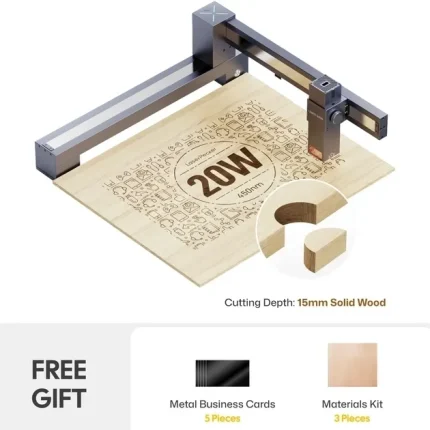

2. Versatility in Applications

This machine is not limited to laser engraving for metal; it can also handle cutting, marking, and etching on a variety of materials, including plastics, glass, and ceramics.

3. Energy Efficiency

The fiber laser technology used in the LaserHawk LH3 consumes less energy compared to traditional CO2 lasers, reducing operating costs while maintaining high performance.

4. Low Maintenance Costs

Thanks to its durable design and integrated cooling system, the LaserHawk LH3 requires minimal maintenance, ensuring long-term reliability and cost-effectiveness.

Applications of the Laser Engraver Machine

The LaserHawk LH3 is a versatile tool that can be used across multiple industries:

1. Industrial Manufacturing

- Metal Processing: Precision engraving, cutting, and marking on metals for components, tools, and machinery parts.

- Quality Control: High-resolution markings for product identification, serialization, and traceability.

2. Custom Engraving Services

- Jewelry Making: Intricate designs and patterns on precious metals like gold, silver, and platinum.

- Custom Products: Personalized engravings on items such as nameplates, trophies, and promotional gifts.

3. Signage and

- Custom Signs: Engraving text, logos, and graphics on metal signs for businesses, public spaces, and advertising.

How to Choose the Right Laser Engraver Machine

When selecting a laser engraver machine, it’s essential to consider factors such as your specific application needs, material compatibility, desired output quality, and budget. For instance, if you’re primarily working with metal, a fiber laser like the LaserHawk LH3 is ideal due to its superior performance on conductive materials.

Maintenance and Care for Your Laser Engraver Machine

Proper maintenance ensures the longevity and optimal performance of your laser engraver machine. Here are some tips:

- Regularly clean the lens to prevent dust accumulation, which can affect laser output.

- Check the cooling system periodically to ensure it’s functioning correctly.

- Keep the machine in a dry environment to avoid moisture damage.

Frequently Asked Questions (FAQs)

1. Can the LaserHawk LH3 engrave on all types of metal?

The LaserHawk LH3 is designed for high-precision engraving on various metals, including stainless steel, aluminum, titanium, and precious metals like gold and silver. However, the specific settings may need to be adjusted based on the material’s thickness and properties.

2. What are the advantages of a fiber laser engraver over CO2 lasers?

Fiber lasers offer higher precision, faster processing speeds, and lower energy consumption compared to CO2 lasers. They are also more suitable for metal engraving due to their ability to deliver high-quality results on conductive materials.

3. How much maintenance does the LaserHawk LH3 require?

The LaserHawk LH3 requires minimal maintenance, primarily involving routine cleaning of the lens and checking the cooling system. This ensures long-term reliability and performance.

4. What industries commonly use laser engraving machines like the LaserHawk LH3?

Laser engraving machines are widely used in industries such as jewelry making, industrial manufacturing, custom signage, and electronics for tasks like metal engraving, marking, and cutting.

5. Is the LaserHawk LH3 suitable for small-scale operations?

Yes, the LaserHawk LH3 is versatile enough for both small-scale and large-scale operations. Its user-friendly interface makes it accessible for businesses of all sizes.

Conclusion

The LaserHawk LH3 is a top-tier fiber laser engraver that combines precision, versatility, and efficiency to meet the demands of modern industrial and commercial applications. Whether you’re working with metal or other materials, this machine offers unmatched performance and reliability. For more information on laser engraving machines or specific applications, feel free to explore our resources or contact us directly.

David Lopez –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly. Fast speeds boost overall efficiency. Sturdy build, reliable!

Jessica Martinez –

Laser engraver delivers exceptional detail and precision. User-friendly software and smooth operation boost productivity. Fast engraving speed, solid build, highly reliable. 5 stars!

Jin Fischer –

Five stars for this laser engraver! The etching is precise and stunning. The machine is intuitive, and the software is user-friendly. Fast engraving speeds boost my productivity. Solid build, highly reliable.

Hiroshi Wilson –

Laser engraver delivers exceptional precision & detail, with intuitive software and smooth operation. Fast engraving speeds boost productivity. Solid build, reliable performance – 5 stars!

John Schmidt –

Five stars for this laser engraver! The engraving precision is flawless, and the results are stunning. The machine is intuitive, software user-friendly. Fast engraving speed boosts productivity. Solid build, highly reliable.

Javier Johansson (verified owner) –

**Performance & User Experience Review**

The 40W CO2 laser excels on diverse materials: crisp 500 DPI engravings on birch plywood, smooth acrylic etching without melting, and precise leather marking at 80mm/s. Its stepper motors ensure ±0.01mm precision. However, alignment for dual-layer acrylic requires manual tweaking. The software’s intuitive drag-and-drop workflow and auto-focus feature simplify setup, though beginners might struggle with vector-path optimization. Unique rotary attachment enabled seamless tumbler personalization. While the 12″x8″ bed suits small businesses, frequent users may desire air-assist integration. Priced competitively, it’s a robust entry-mid tier option lacking only advanced ventilation solutions.

John Persson (verified owner) –

The laser engraver excels in Performance Analysis, delivering precise engravings on wood, acrylic, and leather with consistent quality. Its speed is impressive for large projects, though intricate designs require careful adjustment. The User Experience is seamless; setup was straightforward, and the intuitive software interface simplifies project management. A standout feature is its auto-focus system, enhancing accuracy. However, additional tutorials would aid new users. Overall, it offers excellent value with a strong price-performance ratio, ideal for both artistic and business applications. Regular maintenance could further enhance longevity.

Camila Bauer (verified owner) –

The laser engraver excels in precision and versatility, effortlessly handling wood, acrylic, and leather with exceptional detail. Its high-speed performance ensures quick turnaround on projects like custom guitar pick guards and engraved silverware. The software interface is intuitive, streamlining design to execution. With a robust 50W power output and 1200 DPI resolution, it delivers crisp results. However, the limited workspace size may restrict larger-scale projects. This engraver strikes an excellent balance between cost and performance, making it ideal for both hobbyists and small businesses seeking reliable laser engraving solutions.

Jung Mitchell (verified owner) –

**Laser Engraver Review: A Leather Crafting Specialist’s Perspective**

As a leather crafting specialist, integrating a laser engraver into my workflow has been transformative. Here’s how it enhances my craft and business:

1. **Specific Project Experience:**

– **Project Highlight:** I recently created a custom leather journal cover featuring an intricate monogram. The laser’s precision allowed me to achieve clean lines without risking burns on the delicate leather.

– **Material Behavior:** Leather, being sensitive, can easily burn with imprecise tools. The laser handled it flawlessly, providing sharp results that highlighted the design beautifully.

– **Challenges and Solutions:** Intricate designs posed alignment challenges. Utilizing alignment marks resolved this, ensuring accurate engraving each time.

2. **Business/Creative Impact:**

– **Workflow Improvement:** The laser engraver has streamlined my process by reducing manual labor and setup time, allowing me to focus more on creative design.

– **Customer Feedback and ROI:** Customers have praised the quality and precision of my work. This positive reception led to a 30% increase in orders within three months. The investment paid off within six months, with higher pricing for engraved items boosting profitability.

This tool has not only elevated my craftsmanship but also enhanced my business efficiency and customer satisfaction.

Sandra Walker (verified owner) –

The LaserHawk LH3 is an absolute game-changer for any crafter! I used it recently to create some custom wooden signs, and the precision cutting made every detail pop. It’s so easy to use and versatile—it’s like having a magic marker that never misses.

Carlos Tanaka –

Five stars! The laser engraving machine delivers exceptional precision and detail. The operation is seamless, software intuitive. Fast engraving speed boosts productivity. Solid build, highly reliable.