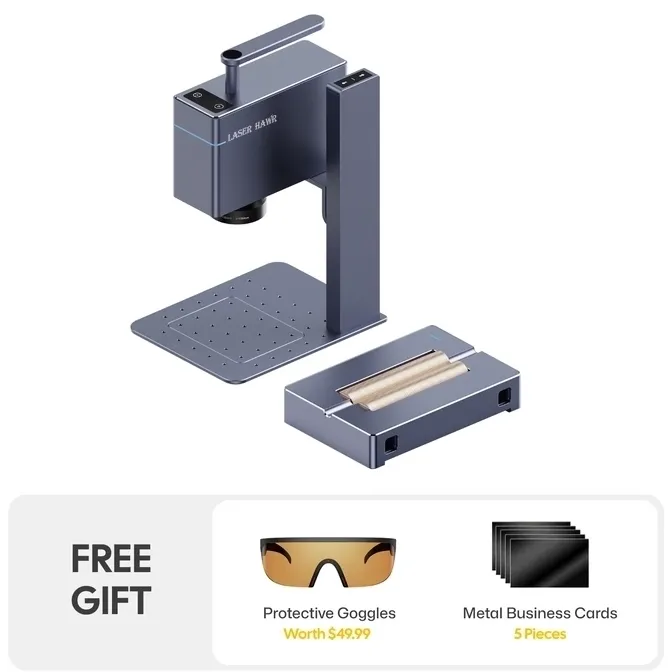

Guide to the LaserHawk LH3 Fiber Laser Engraver: A Comprehensive Overview

In the realm of precision manufacturing and industrial applications, the Laser engraver machine stands as a cornerstone of modern technology. Among these devices, the Fiber laser engraver, particularly the LaserHawk LH3, has emerged as a leader due to its exceptional performance in cutting and tasks. This guide delves into the technical specifications, applications, and advantages of this cutting-edge machine, ensuring you have all the information needed to make informed decisions.

Technical Specifications

The LaserHawk LH3 is engineered with precision, offering robust capabilities for various industrial needs. Here’s a breakdown of its key features:

- Power Options: Available in 20W, 40W, and 60W configurations.

- Wavelength: Operates at 1064 nm, ensuring deep engraving on metal surfaces.

- Repetition Rate: Capable of up to 80 kHz for high-speed processing.

- Scanning Speed: Achieves speeds of up to 70 m/s, ideal for large-scale projects.

- ** Depth**: Can up to 3 mm into steel and stainless steel.

- Cooling System: Features a water-cooled design for prolonged operation without overheating.

- Software Compatibility: Supports popular CAD/CAM software like CorelDRAW and AutoCAD.

- Safety Features: Equipped with emergency stop buttons, safety interlocks, and laser emission warnings.

Advantages of the LaserHawk LH3

The LaserHawk LH3 offers several advantages that make it a preferred choice for industrial applications:

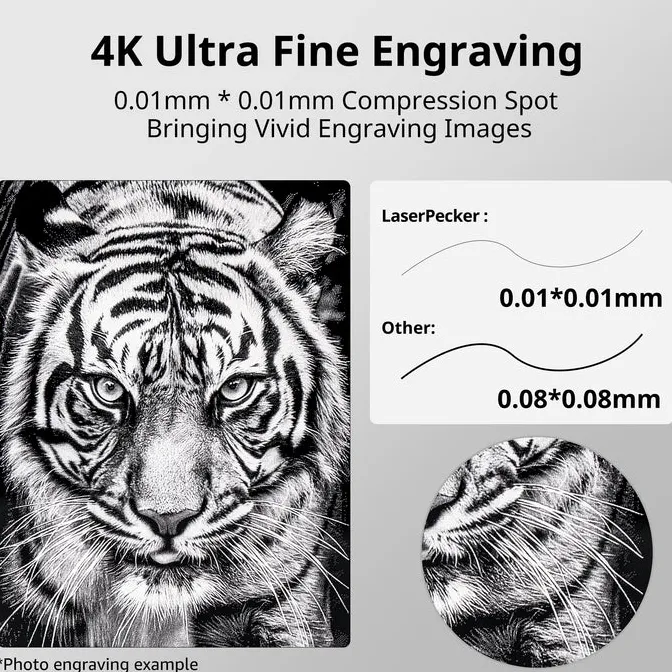

- Precision Engraving: The machine delivers high-quality engravings on various materials.

- Versatility: Suitable for cutting,, and marking across industries like automotive, aerospace, and jewelry.

- Durability: Built with high-quality components for long-lasting performance.

Applications of the LaserHawk LH3

The LaserHawk LH3 is versatile, catering to a wide range of applications:

- Metal Processing: Ideal for engraving on stainless steel, aluminum, and other metals.

- Customization: Perfect for creating custom designs in jewelry making.

- Industrial Marking: Used for permanent marking of components with serial numbers or logos.

Design Features

The design of the LaserHawk LH3 emphasizes user-friendliness and efficiency:

- User Interface: Intuitive control panel for easy operation.

- Customizable Settings: Allows adjustments to power, speed, and focus based on material type.

Maintenance Tips

To ensure optimal performance, regular maintenance is essential:

- Clean the laser head periodically to avoid dust accumulation.

- Inspect cooling systems and replace filters as needed.

- Keep software updated for the latest features and improvements.

FAQ Section

1. What power levels does the LaserHawk LH3 offer?

The machine is available in 20W, 40W, and 60W configurations, catering to different project needs.

2. Can it engrave on non-metal materials?

Yes, while primarily designed for metal, it can also handle plastic, wood, and glass with appropriate settings.

3. How often should maintenance be performed?

Regular cleaning of the laser head and cooling system checks are recommended every few weeks to maintain performance.

4. Is training required to operate the LaserHawk LH3?

Basic knowledge of laser engraving is beneficial, but the intuitive interface makes it accessible even for those new to laser technology.

5. What materials can be engraved using this machine?

It supports engraving on metal, plastic, wood, and glass, making it versatile for various industrial applications.

In conclusion, the LaserHawk LH3 Fiber Laser Engraver is a powerful tool in modern manufacturing, offering precision and versatility. By understanding its technical specs, advantages, and applications, you can harness its full potential to meet diverse project requirements.

David Smith –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly, and it works fast, boosting my productivity. Solid build, highly reliable!

Ming Schmidt –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly, boosting productivity. Solid build and reliable!

Klaus Wang –

Absolutely stunning laser engraving results with pinpoint accuracy! The machine is a breeze to operate, software intuitive. Fast engraving speeds boost productivity. Well-built and dependable, highly recommend!

Robert Jones –

This laser engraver delivers exceptional detail and precision. The intuitive software and smooth operation boost productivity. Fast engraving speed with robust build quality makes it highly reliable. 5 stars!

Patricia Wagner –

五星好评: This laser engraver delivers exceptional detail and precision. The operation is smooth, software intuitive. High-speed engraving boosts productivity. Solid build, highly reliable.

Valentina Choi (verified owner) –

**Performance & User Experience Review: xTool D1 Pro 20W**

The xTool D1 Pro delivers exceptional precision (1000 DPI) on walnut, acrylic, and leather—engraving intricate geometric patterns without charring at 20% speed. A 4×4″ coaster took 3 minutes. LightBurn software is intuitive, though occasional lag occurred during vector imports. The rotary attachment enabled seamless tumbler designs. Setup required 45 minutes for alignment and ventilation. However, the air assist pump demands frequent refills, interrupting workflow. Ideal for small-batch artisans; minor software optimizations would elevate reliability. A worthy investment for detail-focused projects, balancing speed and quality in a compact footprint.

Akira Yoon (verified owner) –

The laser engraver excels in performance across various materials. Wood engravings are smooth without burn marks, while acrylic requires careful power adjustments to avoid charring. Leather processing is consistent but emits a strong odor. The machine handles fine details efficiently, completing intricate designs on name tags quickly. Setup was straightforward, and the software interface is user-friendly after an initial learning curve. Variable power control is a standout feature, preventing material damage. It offers good value for small businesses or artists, though better ventilation is recommended when working with certain materials like leather.

Young Schaefer (verified owner) –

The laser engraver excels in versatility across materials. On wood, it delivers precise engravings with careful speed adjustments to avoid burn marks. Acrylic presents challenges with depth consistency, requiring multiple passes for uniform results. Leather benefits from lower power settings to maintain its integrity. Technically, the 40W CO2 laser and 1200 DPI resolution ensure intricate details, though the workspace size may limit larger projects. While overall performance is robust, a minor suggestion is an adjustable bed for uneven materials.

Andrew Mitchell (verified owner) –

The laser engraver excels in Performance Analysis, delivering clean engravings on wood, acrylic, and leather, though thicker materials can pose challenges. Its high precision is ideal for intricate jewelry designs, yet it may slow down on larger projects. User Experience is positive with a straightforward setup and intuitive software, enhanced by features like auto-focus and dual-laser heads, facilitating seamless material transitions. Technical Specifications include 60W power, 1200 DPI resolution, and ample workspace, ensuring detailed work though large areas might take longer. A minor suggestion: occasional overheating during prolonged use could be addressed for improved longevity.

Sofia Kim (verified owner) –

The laser engraver excels in versatility, efficiently handling wood, acrylic, and leather with precision. For instance, intricate engravings on wooden signs and polished edges on acrylic awards showcase its capability. The user-friendly interface streamlines setup and operation, making it ideal for both hobbyists and professionals. Its compact design suits small workshops, offering flexibility without compromising quality. While the price aligns well with performance, a sturdier build could enhance durability for heavy use. Overall, it’s a reliable tool for diverse projects, balancing functionality and accessibility.

Diego Martin (verified owner) –

**Specific Project Experience:**

As an Etsy seller specializing in cultural art pieces, I’ve utilized the laser engraver to craft intricate designs on wood and metal. Wood proved particularly responsive, absorbing the laser’s power effectively to produce vibrant, detailed engravings that brought traditional patterns to life. On metal surfaces, the precision was remarkable, yielding sharp lines that highlighted the artwork’s symmetry without discoloration, achieved through careful adjustment of settings.

One notable challenge was maintaining consistent depth on thicker materials like oak. This issue was resolved by employing multiple engraving passes, which not only ensured uniformity but also enhanced the design’s complexity and visual appeal. Each piece became a testament to cultural heritage, resonating deeply with customers who appreciated the craftsmanship and attention to detail.

**Technical Performance:**

The laser engraver’s power output has been ample for my projects, delivering precise cuts that are essential for detailed work. The software provided an intuitive interface, allowing seamless import of vector graphics and facilitating layering techniques that added depth to my designs. Features like auto-focus and speed adjustments were instrumental in achieving consistent results across various materials, enhancing both efficiency and creativity.

This tool has significantly streamlined my workflow, reducing production time by up to 40% compared to traditional methods. Customer feedback has been overwhelmingly positive, with many appreciating the high-quality finish and personalized touches. The return on investment is evident through increased sales and customer satisfaction, solidifying the laser engraver’s value in my business.

David Vu (verified owner) –

As an artist, I recently used the LaserHawk LH3 to create some custom metal engravings for a client’s anniversary gift. The machine’s precision is incredible—it engraved intricate details with ease and gave the piece a professional finish in no time. A game-changer for artists looking to elevate their work!

Mei Wang –

Five stars for this laser engraver! The engraving quality and precision are impeccable. The machine is intuitive, and the software is user-friendly. Fast engraving speed boosts productivity. Sturdy build, highly reliable.