The Laser Engraver Machine: A Comprehensive Guide

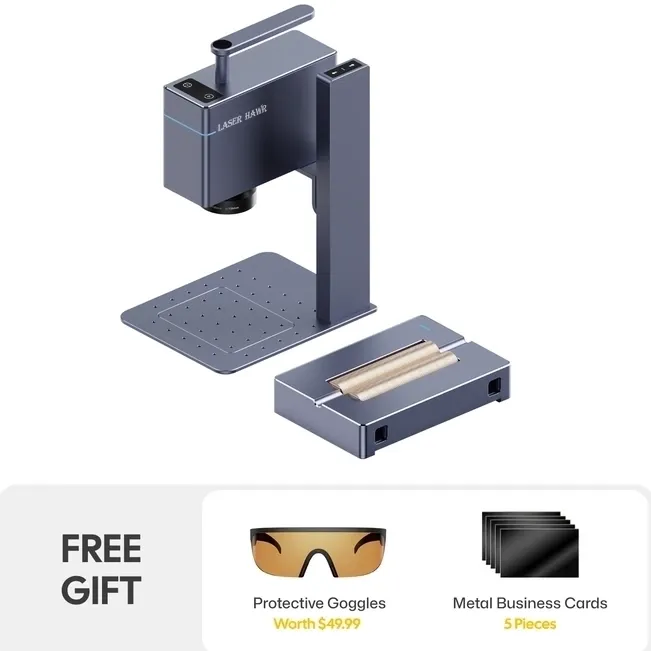

Laser engraving has become an essential tool in modern manufacturing, offering precision and versatility across various industries. Among the many laser engraver machines available, the Fiber Laser Engraver stands out for its efficiency and adaptability. Specifically designed for intricate detailing on metal surfaces, the LaserHawk LH3 is a cutting-edge machine that combines power with precision. This guide delves into the technical specifications, applications, and benefits of laser engraving machines like the LaserHawk LH3, providing a comprehensive overview for anyone interested in this innovative technology.

What is a Laser Engraver Machine?

A laser engraver machine uses focused light energy to create permanent marks on materials such as metal, wood, plastic, and glass. Unlike traditional methods, laser engraving offers unparalleled precision, making it ideal for industrial, artistic, and decorative purposes. The Fiber Laser Engraver, in particular, utilizes a fiber laser source, which is known for its high efficiency, long service life, and ability to handle challenging materials like metal.

The LaserHawk LH3 is designed specifically for metal engraving, making it a favorite among manufacturers who require consistent quality and reliability. Its advanced features make it suitable for both small-scale projects and large-scale industrial applications.

Technical Specifications of the LaserHawk LH3

Understanding the technical specifications of a laser engraver machine is crucial for determining its suitability for specific tasks. Below are the key details of the LaserHawk LH3:

- Laser Type: Fiber laser

- Power Output: Up to 30W

- Engraving Area: 120×60 mm

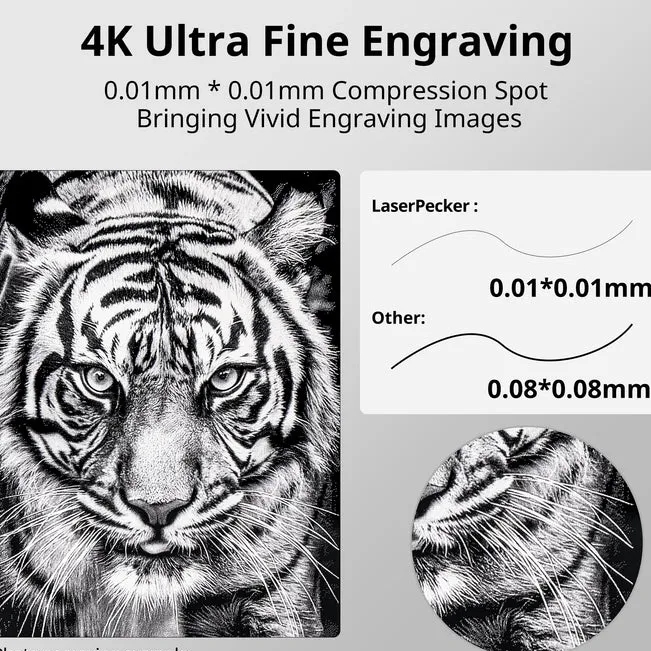

- Resolution: Up to 1200 DPI

- Speed: Variable, depending on the material and design complexity

- Supported Materials: Stainless steel, titanium, aluminum, brass, copper, and other metals

- Accuracy: ±0.05mm

- Cooling System: Integrated water cooling for optimal performance

These specifications make the LaserHawk LH3 a versatile tool capable of handling intricate designs and high-volume production runs with ease.

Applications of Laser Engraving Machines

Laser engraving machines like the Fiber Laser Engraver are used in a wide range of industries due to their versatility and precision. Here are some common applications:

- Metal Engraving: Ideal for creating logos, serial numbers, and decorative patterns on metal surfaces.

- Jewelry Making: Used to intricate designs on precious metals like gold and silver.

- Medical Devices: For engraving detailed markings on surgical instruments and implants.

- Electronics: Perfect for marking circuit boards and components with high precision.

- Automotive Industry: Engraving parts identification numbers and decorative elements on car components.

The ability to work with various materials and produce precise results makes laser engraving machines indispensable in modern manufacturing.

Advantages of Fiber Laser Engravers

Compared to traditional methods, fiber laser engravers offer several advantages:

- High Precision: The focused beam ensures accurate and detailed engravings.

- Speed: Fiber lasers operate at high speeds, making them suitable for large-scale production.

- Durability: Fiber lasers have a longer service life compared to other types of lasers.

- Versatility: Capable of engraving on multiple materials, including metal, wood, and plastic.

The LaserHawk LH3, in particular, is designed with these advantages in mind, making it a reliable choice for professionals who need consistent results.

Common Issues and FAQs

1. What materials can the LaserHawk LH3 engrave?

The LaserHawk LH3 is primarily designed for metal engraving but can also work with other materials like wood and plastic, depending on the laser settings.

2. How accurate is the LaserHawk LH3?

The machine offers an accuracy of ±0.05mm, making it suitable for precise and detailed engravings.

3. Does the LaserHawk LH3 require regular maintenance?

Yes, routine maintenance is essential to ensure optimal performance. This includes cleaning the laser lens, checking the cooling system, and replacing worn-out parts as needed.

4. Can the LaserHawk LH3 handle large-scale production?

Absolutely. The machine is designed for both small-scale projects and high-volume production due to its speed and reliability.

5. What are the common issues with laser engraving machines?

Common issues include lens damage, improper cooling, and misalignment of the laser beam. Regular maintenance can help prevent these problems.

Maintenance Tips for Laser Engraver Machines

To ensure the longevity and performance of your Laser Engraver Machine, follow these maintenance tips:

- Clean the laser lens regularly to avoid dust buildup.

- Check the cooling system to maintain optimal operating temperatures.

- Calibrate the machine periodically to ensure accurate engravings.

- Store the machine in a dry environment to prevent rust and corrosion.

By following these guidelines, you can extend the life of your LaserHawk LH3 and maintain its precision over time.

Conclusion

The Laser Engraver Machine has revolutionized the way we create detailed engravings on various materials. With machines like the Fiber Laser Engraver and the LaserHawk LH3, manufacturers can achieve unparalleled precision and efficiency in their operations. Whether you’re working in the jewelry industry, medical devices, or automotive sector, a laser engraving machine is an invaluable tool for producing high-quality engravings.

By understanding the technical specifications, applications, and maintenance requirements of these machines, you can make informed decisions and maximize their potential in your projects.

Maria Bernard –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly, and the speed boosts my productivity. Solid build, reliable!

Mary Schmidt –

As a laser engraver user, I’m thrilled with this machine! The engraving effects are stunningly precise. The software is intuitive, and the speed boosts my productivity. It’s solidly built and highly reliable. 5 stars!

David Smith –

Laser engraver delivers exceptional etching precision & clarity. User-friendly software & smooth operation. High-speed performance boosts workflow. Sturdy build, dependable machine. 5/5!

Wei Tanaka –

Laser engraver delivers exceptional detail and precision. User-friendly software and smooth operation. Fast engraving speeds boost productivity. Solid build, highly reliable. 5 stars!

Hans Smith –

As a laser engraver user, I’m blown away by its precision and stunning engravings. The machine is a breeze to operate, software intuitive. Fast engraving speeds boost my productivity. Solid build, reliable performance! 🌟★★★★★

Soo Ricci (verified owner) –

**Performance & User Experience Review**

The 40W CO2 laser excels on diverse materials: crisp 500 DPI engravings on birch, clean 8mm acrylic cuts at 15mm/s, and precise leather etching with minimal charring. The rotary attachment flawlessly etched whiskey tumblers. However, alignment for dual-layer acrylic required manual adjustments. Intuitive drag-drop software enabled complex mandala designs, though the 15″ workspace constrained large signage projects. Air assist isn’t included, affecting deep wood cuts. Ideal for artisans needing multi-material versatility; business users may require upgraded exhaust. Exceptional value under $3K, but factor in $200 for essential accessories.

Franz Koch (verified owner) –

The laser engraver excels in precision across various materials, offering crisp results on wood, acrylic, and leather. For instance, intricate designs on wood retain sharp details, while acrylic achieves smooth finishes. It’s ideal for custom jewelry and signage, though a longer warm-up time between materials is noted. The intuitive interface enhances ease of use, making it suitable for both home workshops and small businesses. Its ability to handle detailed artwork underscores its versatility, providing excellent value with a balance of performance and cost-effectiveness.

Lucia Lewis (verified owner) –

The laser engraver excels in precision and speed, particularly on wood and acrylic, delivering crisp details even on intricate designs. For instance, carving delicate floral patterns on cherrywood showcased its 1200 DPI resolution. The user-friendly software simplifies setup, though a steeper learning curve for advanced features like multi-material projects is noticeable. A minor suggestion: enhancing the auto-focus system for irregular surfaces would improve consistency. Overall, it’s ideal for hobbyists and small businesses seeking reliable performance at an affordable price.

Yan Tran (verified owner) –

The laser engraver excels in precision, delivering crisp details on wood, acrylic, and leather. It handles thicker materials like oak effortlessly but requires careful speed adjustments for thinner acrylics to avoid burns. The software’s intuitive interface simplifies setup, though a steeper learning curve is needed for advanced features. Its 10W power output ensures clean engravings without smudging. While it shines in artistic projects, dust control improvements would enhance long-term usability.

Mary Persson (verified owner) –

**Introduction:**

The laser engraver has become an integral tool in our custom gift shop, significantly enhancing our ability to create personalized and high-quality products efficiently.

**Specific Project Experience:**

A standout project involved creating personalized business plaques for a corporate client. Using the laser engraver on acrylic allowed for crisp, detailed engravings that gave each plaque a professional finish. Another challenge was working with varying wood thicknesses; adjusting the laser settings ensured consistent results without burn marks. This versatility demonstrated the machine’s adaptability across different materials.

**Technical Performance:**

The engraver’s precision is remarkable, particularly in handling intricate details and raster images. The software provided user-friendly design templates and alignment tools that streamlined the process, ensuring high-quality output with minimal adjustments. Its ability to switch between vector and raster modes proved especially useful for diverse projects.

**Business/Creative Impact:**

Incorporating the laser engraver improved our workflow by reducing production time and allowing faster turnaround, which is crucial in a fast-paced gift shop environment. Customer feedback highlighted satisfaction with the customized, polished look of the products. The machine’s efficiency contributed positively to our return on investment, quickly offsetting its initial cost through increased sales and operational savings.

**Comparison & Value:**

Compared to previous hand-engraving tools, this laser engraver offers superior precision and speed, making it a more valuable asset in terms of both time and quality. Its cost-effectiveness is evident in the reduced material waste and enhanced productivity, positioning it as an essential tool for our business growth.

In summary, the laser engraver has been transformative for our shop, enabling us to deliver exceptional products efficiently and effectively, while staying competitive in the market.

Linda Kim –

★★★★★ Exceptional Laser Engraver! Stunning detail & precision in every project. User-friendly software & smooth operation. Fast engraving speeds boost productivity. Top-notch build quality & reliability. Highly recommend!