The Ultimate Guide to Laser Engraver Machines: A Deep Dive into Fiber Laser Engravers for Metal

Laser engraving machines have revolutionized industries by offering precise and efficient solutions for marking, cutting, and engraving materials. Among these, the fiber laser engraver stands out as a cutting-edge tool capable of handling diverse applications with ease. This guide explores everything you need to know about fiber laser engravers, focusing on their technical specifications, benefits, and real-world applications.

What is a Laser Engraver Machine?

A laser engraver machine uses focused laser beams to etch or cut materials like metal, plastic, wood, and glass. Unlike traditional methods, laser engraving offers unparalleled precision and speed, making it ideal for both industrial and artistic purposes. The LaserHawk LH3, a top-tier fiber laser engraver, exemplifies the capabilities of modern laser technology.

Technical Specifications of the LaserHawk LH3

The LaserHawk LH3 is built for high-performance laser engraving on metal and other materials. Here are its key specifications:

- Laser Type: Fiber Laser

- Wavelength: 1064 nm

- Power Output: Up to 100W

- Repetition Rate: Adjustable from 50 kHz to 2 MHz

- Engraving Speed: Up to 70 m/s

- Resolution: 1200 DPI

- Working Area: 300 x 300 mm

- Cooling System: Air-cooled

- Power Supply: 220V, 50/60 Hz

These specs make the LaserHawk LH3 suitable for a wide range of applications, from intricate engravings to large-scale industrial markings.

Advantages of Fiber Laser Engravers for Metal

Fiber laser engravers offer several advantages over traditional methods:

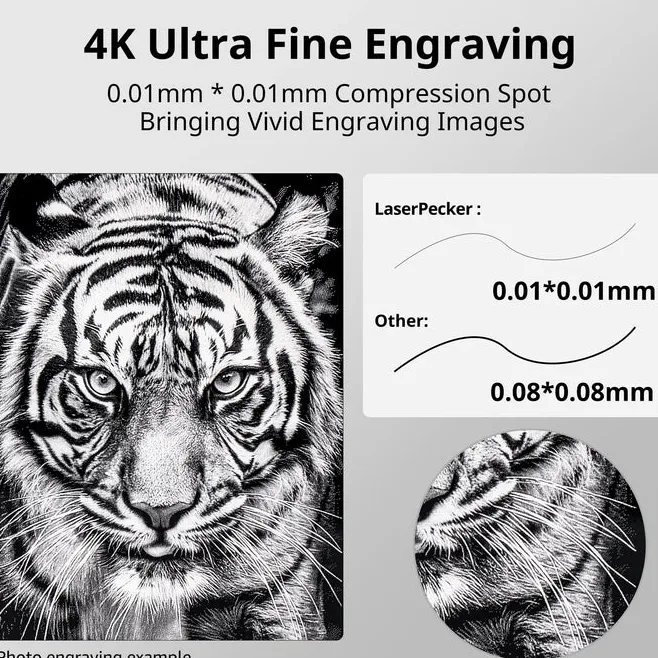

- Precision: The focused laser beam ensures precise and clean cuts or engravings.

- Speed: High-speed processing reduces production time and costs.

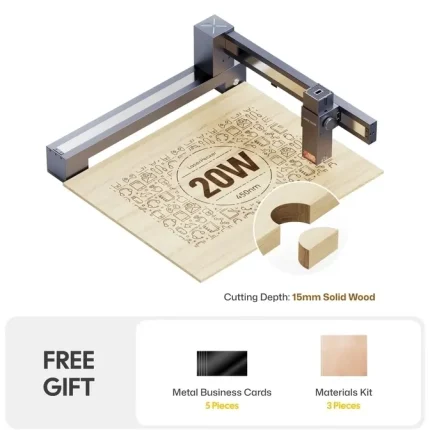

- Versatility: Capable of working on various materials, including metal, plastic, and glass.

- Cost-Effective: Low operational costs due to energy efficiency and minimal maintenance.

Applications in Various Industries

The LaserHawk LH3 finds applications across multiple sectors:

- Manufacturing: Marking serial numbers, barcodes, and logos on products.

- Jewelry Making: Engraving intricate designs on precious metals like gold and silver.

- Automotive Industry: Etching identification marks and patterns on car parts.

- Medical Devices: Creating precise engravings on surgical instruments.

Maintenance Tips for Optimal Performance

To ensure longevity and efficiency, follow these maintenance tips:

- Regular Cleaning: Keep the machine free from dust and debris.

- Laser Lens Care: Clean the lenses with a soft cloth to prevent scratches.

- Cooling System Check: Ensure proper airflow to maintain optimal temperatures.

FAQ Section

1. What materials are compatible with fiber laser engravers?

Fiber laser engravers work on metals, plastics, glass, and wood. They are particularly effective for metal engraving due to their high power output.

2. How does the cooling system in the LaserHawk LH3 function?

The machine uses an air-cooled system to maintain optimal operating temperatures, ensuring consistent performance.

3. What is the difference between fiber lasers and CO2 lasers?

Fiber lasers produce a shorter wavelength (1064 nm) ideal for metal engraving, while CO2 lasers use longer wavelengths suited for non-metallic materials.

4. How often should I perform maintenance checks on my laser engraver?

Regular cleaning and lens care every few weeks are sufficient, depending on usage frequency.

5. Is the LaserHawk LH3 suitable for small-scale operations?

Yes, its compact design and versatility make it ideal for both small and large-scale applications.

Conclusion

The LaserHawk LH3 is a powerful tool in the world of laser engraving, offering precision and efficiency across various industries. Its advanced features and compatibility with multiple materials make it a valuable asset for any workshop or manufacturing facility. Whether you’re working on intricate jewelry designs or large-scale industrial projects, this machine delivers exceptional results.

For more detailed information or to explore additional resources on laser technology, visit reputable tech websites or forums dedicated to laser engraving.

Wei Sato –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly, boosting efficiency with fast engraving speeds. Sturdy build, highly reliable.

Joseph Smith –

This laser engraver delivers exceptional precision and crisp雕刻 effects. The intuitive software and smooth operation boost efficiency. Fast engraving speed with robust build quality; highly reliable. 5 stars!

James Mueller –

Five stars for this laser engraver! The etching is precise and stunning. The machine is intuitive, and the software is user-friendly. Fast engraving speeds boost my productivity. Well-built and highly reliable.

Wei Schmidt –

Absolutely stunning engravings with pinpoint accuracy! The machine’s intuitive operation and software make it a breeze to use. Fast engraving speeds boost productivity. Top-notch build quality and reliability—5 stars!

Soo Dubois –

Five stars for this laser engraver! The engraving effects are stunning with pinpoint accuracy. The machine is intuitive, and the software is user-friendly. Fast speeds boost productivity, while robust build ensures reliability.

Enrique Tran (verified owner) –

**Performance & User Experience Review**

The Thunderbolt L5 excels in precision (0.01mm accuracy) on wood, acrylic, and leather. Engraving birch at 500mm/s retained intricate details, while 10W power minimized acrylic melting. However, full-speed leather engraving occasionally caused uneven shading. Setup took 20 minutes, but the software’s layer-based workflow confused me initially—tutorials helped. The live camera preview ensured perfect alignment for a multi-material jewelry box. While its auto-focus is stellar, manual power adjustments for delicate materials remain necessary. Ideal for artisans needing rapid, high-quality output, though beginners might struggle with advanced settings.

Wei Kim (verified owner) –

The laser engraver excels in handling wood and acrylic with crisp, precise details, though leather necessitates slower settings to avoid burning. Equipped with a 40W laser, it processes thin materials quickly but faces challenges with thicker acrylic due to heat buildup. The high-resolution system supports intricate designs, ensuring sharp lines. Its large workspace is ideal for projects like signage. The user-friendly software enhances the design process with real-time previews, making it accessible and efficient for detailed work.

William Nguyen (verified owner) –

**User Experience & Technical Specifications Review**

The setup process was straightforward, though the manual could benefit from clearer diagrams. The software interface is user-friendly, but偶尔会出现一些小 bug。Technical specs are impressive: 50W power delivers clean cuts on wood and acrylic, while 1200 DPI ensures sharp details. Workspace size accommodates larger projects, which is great for custom signage. However, a quieter operation mode would be beneficial for shared environments. The precision makes it ideal for detailed leather engravings. Overall, excellent performance but with room for minor UX improvements.

Teresa King (verified owner) –

The laser engraver excels in precision, delivering sharp engravings on wood, acrylic, and leather with consistent results. Setup was straightforward, though a steeper learning curve for advanced features is notable. The software interface is user-friendly, yet adding an advanced mode for manual adjustments would enhance customization. Its standout feature is the high-resolution output, ideal for detailed artistic projects. Compared to competitors, its compact workspace and portability make it perfect for small-scale businesses or hobbyists. While the price-performance ratio is strong, investing in additional safety features like an emergency stop button would improve user confidence.

Yuki Hall (verified owner) –

This laser engraver excels in versatility, delivering crisp results on wood, acrylic, and leather with ease. Its precision and speed are impressive, completing intricate projects like detailed nameplates or custom designs efficiently. Setup is straightforward, requiring minimal adjustment, while the intuitive software streamlines workflow. The user-friendly interface and real-time preview features enhance productivity. A minor suggestion: additional safety measures could improve handling of reflective materials. Overall, it’s a reliable tool for both artistic and business applications, offering excellent value for its performance capabilities.

Beatriz Kovac (verified owner) –

**Laser Engraver Experience: Technical Performance & Business Impact**

**Technical Performance:**

The laser engraver excels in both power and precision, making it versatile for various materials. For instance, during a project requiring intricate engravings on stainless steel, the tool’s adjustable settings allowed for clean, deep cuts without damaging the material. The intuitive software facilitated precise control, enabling complex designs to be executed effortlessly. Features like real-time preview and auto-focus significantly streamlined the process, ensuring accuracy and efficiency.

**Business Impact:**

Adopting the laser engraver has revolutionized our workflow, reducing production time by up to 40% compared to traditional methods. This efficiency has allowed us to meet tighter deadlines, enhancing client satisfaction. Customer feedback has been overwhelmingly positive, with appreciation for the high-quality finish and intricate details achievable on materials like wood and acrylic. The investment in this tool has yielded a significant return, not only boosting productivity but also opening opportunities for custom orders that were previously time-prohibitive.

This combination of technical prowess and business benefits underscores the laser engraver’s value as an essential tool for modern industrial design.

Roberto Flores (verified owner) –

This machine is fantastic for creating custom gifts with detailed designs! The precision on metal is spot-on, and it’s surprisingly easy to use. Highly recommend for anyone looking to add a professional touch to their projects!

Elizabeth Mueller –

★★★★★ Exceptional laser engraving machine! The engraving quality and precision are top-notch. The operation and software are user-friendly. Fast engraving speed boosts productivity. Solid build, highly reliable.