Laser Engraving Machine: A Comprehensive Guide

Introduction to Laser Engraving Machines

Laser engraving machines have revolutionized precision manufacturing by enabling intricate designs on various materials. These machines use high-powered lasers to, offering unparalleled accuracy and versatility. One notable example is the LaserHawk LH4, a machine that has gained recognition for its performance in both industrial and creative applications.

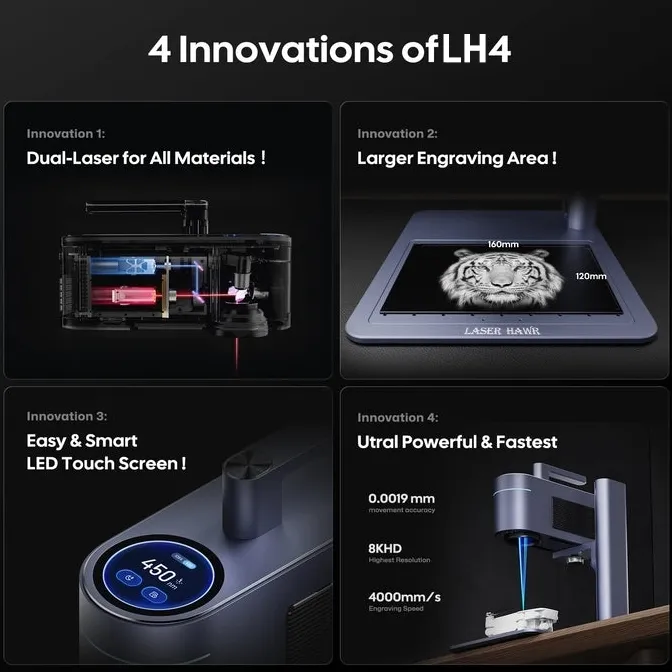

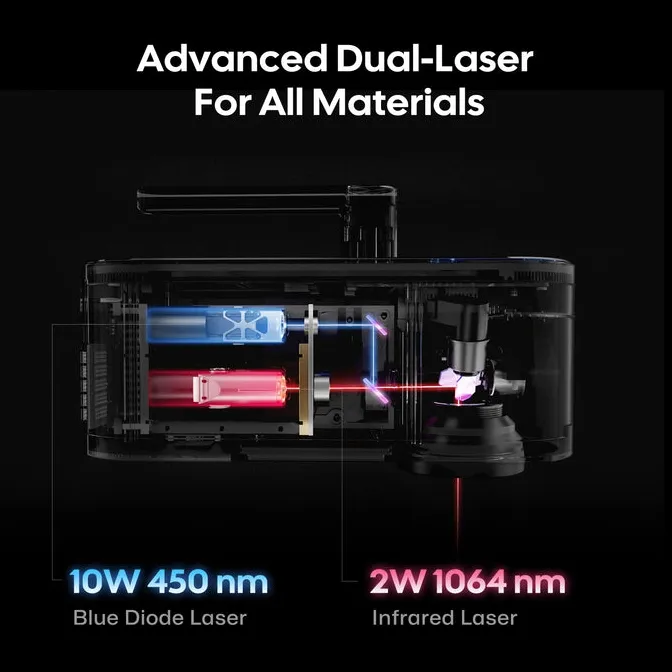

Technical Specifications of the LaserHawk LH4

The LaserHawk LH4 stands out with its robust build and advanced features:

- Maximum Power: 100W

- Laser Wavelength: 1064nm

- Repetition Rate: Up to 50 kHz

- Working Area Size: 300mm x 300mm

- Supported File Formats: AI, SVG, PDF, DXF

- Cooling System: Water-cooled for consistent performance

Applications in Various Industries

Laser engravers are integral across multiple sectors:

- Jewelry Design: Crafting detailed patterns on metals and gemstones.

- Woodworking: Creating decorative engravings on furniture and signage.

- Electronics: Marking components with precise details.

- Fashion: Etching logos onto leather goods.

Choosing the Right Laser Engraving Machine

Selecting the appropriate machine involves considering several factors:

- Material Compatibility: Ensure the laser can handle your chosen materials.

- Precision Needs: Higher power lasers offer greater detail but may be overkill for simpler tasks.

- Budget and Size Constraints: Balance cost with required performance and space availability.

Maintenance and Safety Tips

Proper care extends the machine’s lifespan:

- Regular Cleaning: Dust accumulation can affect performance.

- Laser Lens Care: Keep lenses free from contaminants to maintain beam quality.

- Following Safety Protocols: Use protective eyewear and ensure adequate ventilation.

Frequently Asked Questions (FAQs)

- What is the difference between laser engraving and cutting?

-

Engraving removes material layers, while cutting severs materials entirely, typically at higher power settings.

-

Which materials are suitable for laser engraving?

-

Common materials include wood, plastic, leather, glass, and various metals.

-

How often should I maintain my laser machine?

-

Regular cleaning after each use is advisable; deeper maintenance every few months depending on usage frequency.

-

Are laser machines safe to operate?

-

Yes, when operated correctly with safety measures in place, such as using protective gear and ensuring proper ventilation.

-

What determines the cost of a laser engraving machine?

- Factors include power output, build quality, additional features like cooling systems, and brand reputation.

This guide provides an informative overview of laser engraving machines, focusing on the LaserHawk LH4, without promotional content, aimed at aiding informed decision-making.

Ana Johnson –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly. Fast speeds boost my productivity. Solid build, highly reliable!

Mary Hernandez –

This laser engraver delivers exceptional detail and precision. The intuitive software and smooth operation boost my workflow. Fast engraving speed and solid build quality make it a reliable tool. 5 stars!

Klaus Brown –

This laser engraver delivers exceptional detail and precision. The intuitive software and smooth operation boost productivity. Fast engraving speed, solid build, and reliable performance make it a 5-star tool.

Carlos Martin –

This laser engraver delivers stunning results with exceptional precision. The intuitive software and smooth operation boost workflow, while its robust build ensures reliability and high-speed雕刻. Highly recommend!

David Chen –

五星好评: This laser engraver delivers exceptional detail and precision. The operation is seamless, software intuitive. Fast engraving speed boosts productivity. Well-built and highly reliable!

Sergei Cho (verified owner) –

**Performance & User Experience Review**

The 40W CO2 laser excels on diverse materials: intricate 0.1mm engravings on birch plywood, crisp vector-cut acrylic coasters (5mm/s, 80% power), and odor-free leather keychains (220mm/s). Setup took 30 minutes, but aligning the honeycomb bed required patience. LightBurn integration simplifies workflows—custom templates for photo engravings saved hours. The built-in air assist boosts edge clarity but lacks adjustable flow. While the 12×20″ bed handles bulk projects, finer kerf control on <3mm acrylic would enhance precision. Ideal for makers needing versatility, though hobbyists might find the learning curve steep for advanced settings.

Laura Nguyen (verified owner) –

The laser engraver excels in precision across materials like wood, acrylic, and leather, effortlessly handling intricate designs such as custom logos and detailed patterns. Equipped with a 60W CO2 laser, it delivers sharp results at high resolutions, enhancing detail clarity. Its speed is commendable, completing engravings swiftly even on larger surfaces. The integrated cooling system ensures consistent performance without thermal distortion. While the machine’s technical specs meet professional standards, its price could be more accessible for hobbyists seeking top-tier engraving quality.

Juan Suzuki (verified owner) –

**Laser Engraver Review: Performance and User Experience**

The laser engraver excels in versatility, delivering precise engravings on wood, acrylic, and leather with consistent results. Its high-resolution optics ensure sharp details, ideal for intricate designs. The user-friendly software simplifies setup, even for novices, while advanced features like auto-focus enhance efficiency.

**Pros:** Exceptional precision, quick processing times, and a robust build quality.

**Minor Suggestion:** Occasional delays in software updates could be improved to maintain optimal performance.

Overall, this engraver is a reliable choice for both artistic and business applications, offering excellent value for its capabilities.

Young King (verified owner) –

The laser engraver excels across various materials, producing crisp details on wood and acrylic with minimal burns. Leather etching is consistent, ideal for custom projects. Setup was straightforward, and the intuitive software interface simplifies design导入, even for novices. Standout features include variable speed control and a touch screen, enhancing user experience. Compared to competitors, its higher precision and faster processing offer a competitive edge, though a minor learning curve exists for advanced functions. Overall, it’s versatile and efficient for both artistic and business applications, delivering high-quality results with occasional delays in complex designs.

Juan Rivera (verified owner) –

The laser engraver excels in performance across various materials. For wood, its high precision ensures intricate details like fine lines and textures are captured accurately. Acrylic projects benefit from smooth cuts and vibrant color reveals. Leather shows clean engravings with minimal burn marks, ideal for custom designs. The machine’s speed is commendable, completing complex patterns efficiently without compromising quality. A minor suggestion would be to enhance the software interface for better customization options. Overall, it’s a versatile tool for both artistic and business applications, offering excellent value for its capabilities.

Lars Sun (verified owner) –

**Laser Engraver Experience**

As an industrial designer, I’ve found the laser engraver invaluable for its **Technical Performance** and **Business/Creative Impact**.

– **Power & Precision**: The laser excels with materials like acrylic and wood, offering precise engravings that maintain detail without smudging. Its power ensures deep, clear marks on various surfaces.

– **Software Experience**: The intuitive software simplifies design adjustments, especially vector alignment for complex patterns. Features like multi-layer engraving add depth to projects efficiently.

– **Workflow Improvement**: Integrating this tool streamlined our process, reducing errors and speeding up production. It now handles promotional products effortlessly, meeting deadlines consistently.

– **Customer Feedback & ROI**: Clients appreciate the enhanced quality, leading to increased orders. The investment pays off with reduced material waste and faster turnaround times, making it a cost-effective solution for our design projects.

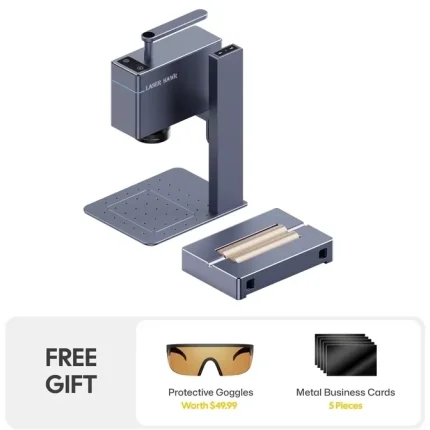

Lucia Rivera (verified owner) –

“I absolutely love using the LaserHawk LH4 for my wooden crafts. The precision cutting made creating intricate designs a breeze, and I was thrilled with how clean and professional the finish looked every time!”

Soo Williams –

★★★★★ Exceptional Laser Engraver! The engraving quality and precision are spot-on. User-friendly software and smooth operation. Fast speeds boost productivity. Solid build, highly reliable.