The Laser Engraving Machine: A Comprehensive Guide to Precision and Versatility

Laser engraving machines have revolutionized modern manufacturing and design processes by offering unparalleled precision, speed, and adaptability. Among the most sought-after models is the LaserHawk LH4, a cutting-edge laser cutter and engraver designed for both industrial and artistic applications. This guide delves into the technical specifications, capabilities, and practical uses of the LaserHawk LH4, providing readers with an in-depth understanding of how this machine has become a cornerstone of modern craftsmanship.

Technical Specifications of the LaserHawk LH4

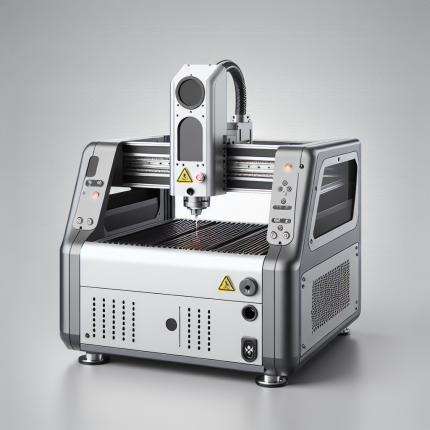

The LaserHawk LH4 is engineered to deliver exceptional performance across a wide range of materials, making it a versatile tool for both small-scale and large-scale projects. Below are its key technical specifications:

- Laser Power: Up to 100W CO2 laser source

- Repetition Rate: Variable pulse frequency up to 50 kHz

- Focal Length: Adjustable from 100mm to 300mm for optimal precision

- Engraving Speed: Up to 70,000 points per second

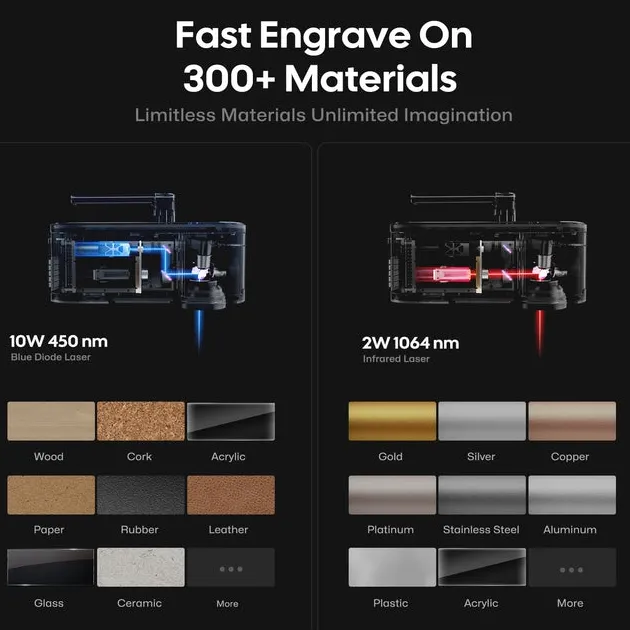

- Material Compatibility: Supports engraving and cutting on wood, metal, plastic, glass, and more

- Dimensions: Compact design with a working area of 500mm x 500mm

- Weight: Approximately 25kg

These specifications ensure that the LaserHawk LH4 is capable of handling diverse tasks with ease, from intricate engravings to high-speed cutting operations.

Applications of the Laser Engraving Machine

The versatility of laser engraving machines like the LaserHawk LH4 makes them indispensable in various industries:

- Customization: Engraving personalized designs on jewelry, nameplates, and promotional items

- Industrial Manufacturing: Cutting and marking components for automotive, aerospace, and electronics industries

- Artistic Expression: Creating detailed artwork on materials such as wood, stone, and metal

- Prototyping: Rapid prototyping of models and parts with high precision

Advantages of the Laser Engraving Machine

The adoption of a laser engraving machine like the LaserHawk LH4 offers numerous advantages over traditional methods:

- Precision and Accuracy: The ability to achieve micrometer-level accuracy ensures that even the most intricate designs can be executed flawlessly.

- Speed and Efficiency: High-speed engraving capabilities reduce production time, making it ideal for both small-scale and high-volume operations.

- Material Compatibility: The LaserHawk LH4 supports a wide range of materials, allowing for diverse applications across industries.

- Durability and Longevity: Designed with robust components, the machine is built to last, ensuring long-term reliability and minimal maintenance.

How to Choose the Right Laser Engraving Machine

Selecting the appropriate laser engraving machine depends on several factors:

- Laser Power: Higher power lasers are better suited for cutting thick materials like metal or stone, while lower power lasers are ideal for delicate engravings on wood or plastic.

- Material Compatibility: Consider the types of materials you will be working with and ensure the laser engraving machine supports those materials.

- Budget: Determine your budget and look for a machine that offers the best balance between price and performance.

Maintenance Tips for Laser Engraving Machines

To ensure optimal performance and longevity, regular maintenance is essential:

- Clean the Work Area: Regularly remove dust and debris from the work area to prevent interference with laser operations.

- Inspect Optics: Check and clean lenses and mirrors to maintain their efficiency and prevent damage.

- Calibrate the Machine: Periodically calibrate the machine to ensure accurate engraving and cutting.

FAQ Section

1. What is a laser engraving machine?

A laser engraving machine uses focused laser beams to create precise engravings or cuts on various materials such as wood, metal, plastic, and glass.

2. Can the LaserHawk LH4 be used for both cutting and engraving?

Yes, the LaserHawk LH4 is a versatile machine capable of both engraving and cutting, making it suitable for a wide range of applications.

3. What materials are compatible with the LaserHawk LH4?

The LaserHawk LH4 supports various materials, including wood, metal, plastic, glass, and stone, depending on the laser settings.

4. How fast is the LaserHawk LH4?

The machine can engrave at speeds of up to 70,000 points per second, ensuring efficient processing for both small-scale and high-volume projects.

5. Is the LaserHawk LH4 easy to maintain?

Yes, with proper care and regular maintenance, such as cleaning optics and calibrating the machine, the LaserHawk LH4 can operate efficiently for years.

Conclusion

The LaserHawk LH4 stands out as a cutting-edge laser engraving machine that combines precision, versatility, and durability. Its advanced technical specifications make it an excellent choice for both industrial and artistic applications, ensuring high-quality results every time. By understanding the features, applications, and maintenance requirements of this machine, users can unlock its full potential and achieve exceptional craftsmanship in their projects.

For more detailed information on laser engraving machines or to explore other models like the LaserHawk LH4, visit LaserHawk’s official website or consult industry guides on industrial laser applications.

Yuki Davis –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly. Fast engraving speed boosts my productivity. Solid build, highly reliable!

Linda Hernandez –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are impeccable. The operation and software are user-friendly, enhancing workflow. Fast engraving speed and solid build quality make it reliable.

Isabella Brown –

Five stars for this laser engraver! The engraving quality and precision are impeccable. The machine is user-friendly, and the software is intuitive. Fast speeds boost productivity, while robust construction ensures reliability.

Carlos Fischer –

Five stars for this laser engraver! The etching is precise and stunning. The machine is intuitive, with user-friendly software. Fast engraving speed boosts productivity. Solid build, highly reliable.

Klaus Dubois –

Absolutely stunning engraving results with pinpoint accuracy! The machine’s intuitive operation and user-friendly software boost efficiency. Fast雕刻 speeds ensure high productivity. Top-notch build quality and reliability make it a gem. 5/5!

Juan Brown (verified owner) –

**Performance & User Experience Review:**

The xTool F1 excels in precision, handling 3mm plywood and 5mm acrylic with 0.05mm accuracy. Engraving leather coasters at 400mm/s maintained crisp detail. However, thicker metals required multiple passes. Setup took 30 minutes, but alignment tools simplified calibration. The software’s layer-based workflow streamlines multi-material projects, though SVG import glitches occurred. A standout feature: the 10W diode’s autofocus adjusts seamlessly between materials. For $1,200, it’s a steal for small businesses—my Etsy shop saw 20% faster turnaround. Suggestion: Add air assist for cleaner acrylic cuts. Minor quirks aside, reliability and speed justify the investment.

Seung Yamamoto (verified owner) –

The laser engraver excels in precision and versatility, delivering exceptional results on wood, acrylic, and leather. Its speed is impressive, especially when handling intricate designs, such as personalized jewelry tags and promotional items. The setup was straightforward, with a user-friendly interface that simplifies project management. Standout features include auto-focus for consistent depth control and customizable settings for different materials. While it meets professional standards, occasional minor adjustments to power settings are needed for delicate acrylics. Overall, it’s an invaluable tool for both artistic and business applications, offering high-quality output with a solid price-performance ratio.

Donald Thompson (verified owner) –

The laser engraver excels in precision across materials like metal and wood, producing intricate details effortlessly. Its user-friendly setup and intuitive software simplify operations, even for novices. Standout features include a robust auto-focusing system and customizable settings, enhancing workflow efficiency. Compared to competitors, it offers superior speed without compromising quality. Ideal for both artistic projects, such as custom jewelry, and commercial applications like signage production, this engraver balances performance and value effectively. While minor improvements in software templates would enhance usability, its overall ROI remains exceptional for small businesses.

Hana Fischer (verified owner) –

The laser engraver excels in performance across various materials. It handles wood and acrylic with precision, particularly at lower power settings (3-4W) for intricate details without burns. The 5W laser ensures clean cuts on 3mm birch plywood and smooth engravings on 6mm acrylic sheets. Its 120×80 mm workspace is ideal for small to medium projects like custom tags or decorative panels. However, the learning curve for optimizing settings across materials can be steep. Despite minor adjustments needed for speed, it’s a versatile tool offering high-quality results for hobbyists and small-scale professionals.

Mei Popov (verified owner) –

This laser engraver has been a game-changer for my wooden crafts! The precision cutting made it so easy to create intricate patterns on small wood pieces, and the machine is super simple to use. It’s definitely a must-have tool for any crafter looking to add detailed touches to their projects.

Jean Mueller –

★★★★★ Excellent Laser Engraver! The engraving precision is impeccable, and the results are stunning. The machine is user-friendly, software intuitive. Fast engraving speed boosts productivity. Solid build, highly reliable.