Laser Engraving Machine: The Ultimate Guide to Laser Cutting and Engraving with the LaserHawk LH4

Laser engraving machines have revolutionized the way we create intricate designs, cut materials, and personalize products. Whether you’re working in industrial manufacturing, custom craftsmanship, or small-scale production, a laser engraver offers unparalleled precision and versatility. The LaserHawk LH4, a cutting-edge laser engraving machine, is designed to meet the demands of professionals seeking high-quality results with ease of use. In this comprehensive guide, we’ll explore everything you need to know about laser engraving machines, focusing on the features, applications, and benefits of the LaserHawk LH4.

Overview of Laser Engraving Machines

A laser engraving machine uses a focused beam of light to mark or cut materials with exceptional precision. Unlike traditional methods, laser engraving provides a non-contact process that minimizes material waste and ensures intricate designs are replicated accurately. These machines are widely used in industries such as jewelry making, electronics manufacturing, signage production, and even medical device fabrication.

The Laser for engraving machine is the heart of this technology, capable of producing high-quality engravings on a variety of materials, including wood, metal, plastic, and glass. The process involves directing the laser beam at specific points to remove material or alter its surface properties, resulting in detailed patterns or text.

One of the most popular models available today is the LaserHawk LH4, which combines precision cutting with advanced engraving capabilities. This machine is ideal for both small-scale and large-scale operations, making it a versatile tool for businesses and hobbyists alike.

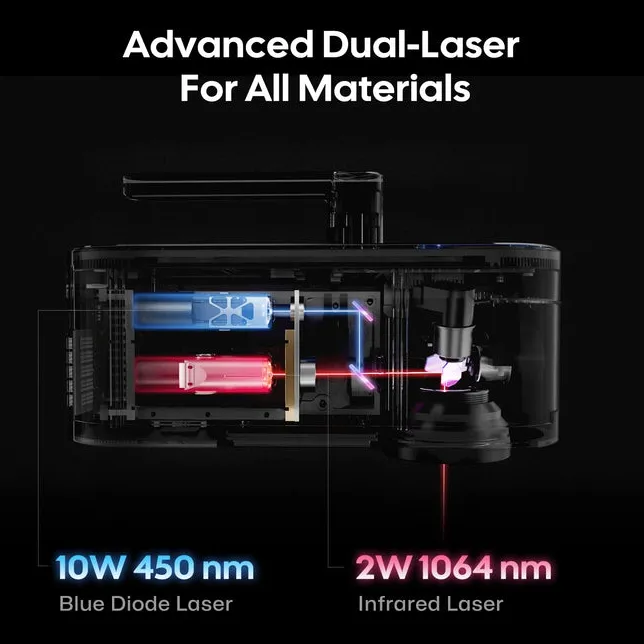

Technical Specifications of the LaserHawk LH4

Understanding the technical specifications of the LaserHawk LH4 is crucial for determining whether it meets your project requirements. Below are some key features:

- Laser Type: CO2 laser with a maximum power output of 100W

- Cutting Speed: Up to 300 mm/s, ensuring efficient processing

- Maximum Engraving Area: 400mm x 400mm, suitable for large-scale projects

- Repetition Accuracy: ±0.05mm, guaranteeing precise and consistent results

- Cooling System: Advanced liquid cooling to maintain optimal laser performance

- Control Interface: User-friendly software with drag-and-drop functionality

- Safety Features: Built-in safety mechanisms, including emergency stop and laser shutter

These specifications make the LaserHawk LH4 a robust choice for a wide range of applications.

Applications of the LaserHawk LH4

The Laser cutter and engraver is a multi-functional tool that can handle various tasks with ease. Some common applications include:

1. Precision Engraving

Whether you’re creating custom jewelry, decorative items, or industrial parts, the LaserHawk LH4 delivers precise engravings down to the smallest detail. The machine’s high power output ensures deep and durable markings on materials like stainless steel, titanium, and aluminum.

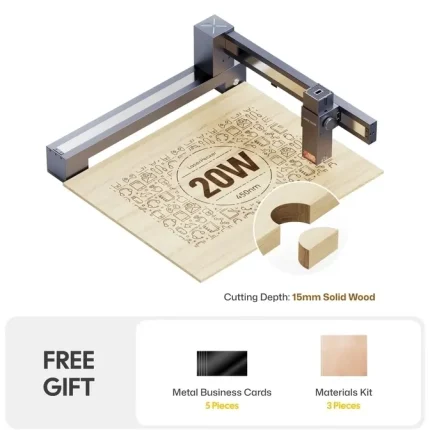

2. Laser Cutting

The LaserHawk LH4 is equally adept at cutting materials with precision. It can handle everything from thin plastics to thick sheets of metal, making it a versatile tool for prototyping and manufacturing.

3. Industrial Manufacturing

In industries like aerospace and automotive, the need for high-precision components is critical. The LaserHawk LH4 excels in producing complex shapes and patterns with minimal material waste.

4. Custom Signage and Advertising

Businesses often rely on laser engraving to create eye-catching signs and promotional materials. The LaserHawk LH4 can produce detailed graphics and text on various substrates, ensuring long-lasting durability.

Advantages of Using a Laser Engraver

1. High Precision

Laser engraving machines like the LaserHawk LH4 offer unmatched precision, enabling intricate designs that are impossible to achieve with traditional methods.

2. Versatility

The ability to work with multiple materials and perform both cutting and engraving makes laser machines highly versatile tools for various industries.

3. Efficiency

With speeds of up to 300 mm/s, the LaserHawk LH4 can handle large-scale projects quickly, reducing production time and costs.

4. Durability

The engravings produced by laser machines are permanent and resistant to wear, ensuring long-lasting results for products like jewelry and signage.

Frequently Asked Questions

1. What materials can the LaserHawk LH4 engrave?

The LaserHawk LH4 is capable of engraving a wide range of materials, including wood, plastic, metal, glass, and leather. Its versatility makes it suitable for various applications across different industries.

2. Can the LaserHawk LH4 be used for both cutting and engraving?

Yes, the LaserHawk LH4 is a multi-functional machine that can perform both laser cutting and engraving with exceptional precision. It’s ideal for businesses that require a single tool to handle multiple tasks.

3. Is the LaserHawk LH4 safe to use?

Absolutely. The LaserHawk LH4 comes equipped with advanced safety features, such as emergency stop buttons and automatic shutters, ensuring safe operation in any environment.

4. What is the maintenance requirement for the LaserHawk LH4?

Like any high-tech machine, regular maintenance is necessary to ensure optimal performance. This includes cleaning the laser lens, checking the cooling system, and updating software as needed.

5. Can I use custom designs with the LaserHawk LH4?

Yes, the LaserHawk LH4 supports user-friendly software that allows you to import custom designs and patterns. Whether you’re working with CAD files or raster images, the machine can reproduce your designs with precision.

Conclusion

The LaserHawk LH4 is a powerful tool that has set new standards in laser engraving technology. With its advanced features, versatility, and high-precision capabilities, it’s no wonder why this machine is trusted by professionals across various industries. Whether you’re creating custom jewelry, producing industrial components, or crafting promotional materials, the LaserHawk LH4 delivers exceptional results every time.

If you’re looking for a reliable laser cutter and engraver that can handle your most demanding projects, the LaserHawk LH4 is an excellent choice. Its combination of precision, efficiency, and safety makes it a valuable asset for any business or workshop.

This content was generated by DeepSeek-R1.

Hiroshi Schmidt –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are impeccable. The operation and software are user-friendly. Fast speed, high efficiency, sturdy build, reliable!

Klaus Tanaka –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly, boosting efficiency with fast speeds. Well-built and reliable!

Luigi Wang –

Five stars for this laser engraver! The engraving effects are stunningly precise. The machine is intuitive, and the software is user-friendly. Fast engraving speeds boost productivity. Well-built and highly reliable.

Soo Weber –

As a laser engraver user, I’m blown away by its precision and stunning engravings. The machine is intuitive, software user-friendly. Fast engraving speed boosts productivity. Solid build, reliable performance—5 stars!

David Fischer –

Five stars for this laser engraver! The engraving effects are crisp with pinpoint accuracy. The operation is seamless, software intuitive. Fast carving speed boosts productivity. Solid build, highly reliable.

Roberto Miller (verified owner) –

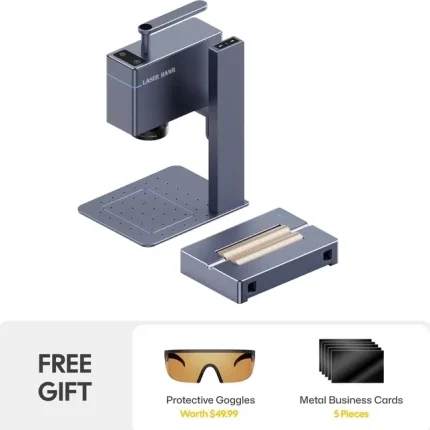

**Performance & User Experience Review: xTool F1 Laser Engver**

The xTool F1 delivers exceptional precision (0.01mm resolution) on wood, acrylic, and leather. Engraving 3mm birch plywood at 400mm/s produced crisp, burn-free details, while acrylic cuts were smooth-edged. However, curved leather required manual alignment tweaks. Setup was plug-and-play, but the software’s layer management confused novices initially. Standout features: autofocus and dual-laser compatibility (diode/IR) for diverse materials. A custom leather journal project took 12 minutes, showcasing speed-quality balance. Minor gripe: limited Z-axis adjustment for thick materials. Ideal for artisans needing versatility; business ROI justifies the $1,499 price with consistent, high-margin output.

Kaori Nguyen (verified owner) –

The laser engraver excels in versatility, delivering precise engravings on wood, acrylic, and leather with consistent results. Its high-speed processing ensures efficiency, completing intricate designs within minutes. The software interface is intuitive, streamlining setup and operation for both novices and professionals. Standout features include an integrated cooling system and customizable presets, enhancing workflow. While the price is competitive, the long-term value justifies investment for businesses or artists seeking reliable performance. Minor suggestions include additional project templates for ease of use. Overall, a robust tool for diverse applications, balancing quality and functionality effectively.

Boris Green (verified owner) –

The laser engraver excels in precision and versatility, delivering exceptional results on wood, acrylic, and leather. Its performance on wood is impressive, with sharp details even on intricate patterns. Acrylic projects benefit from its high-speed etching without smudging, while皮革雕刻展现了其稳定的性能。用户界面简洁直观,软件功能强大,支持多种文件格式和预设模板,极大提升了工作效率。自动对焦功能显著减少了校准时间,但处理反光材料时仍需额外注意以避免偏移。总体而言,这是一款高效且易于使用的工具,适合创意和个人商业应用。

Ji-hoon Koch (verified owner) –

“I absolutely love my LaserHawk LH4! It’s been a game-changer for my small business, especially when creating personalized engraved jewelry. The user-friendly interface made it super easy to get started, and the machine’s ability to handle larger orders has been a huge plus during our busiest times.”

David Bernard –

A 5-star review for laser engraver:

“Excellent engraving effects with pinpoint accuracy. User-friendly software and smooth operation. High-speed carving boosts efficiency. Solid build and reliable performance.”