Laser Engraving and Cutting with LaserHawk LH2: A Comprehensive Guide

In the realm of modern manufacturing and design, laser engraving and cutting have emerged as indispensable techniques, offering precision and versatility. The LaserHawk LH2, a leading machine in this field, stands out for its ability to execute intricate designs with unparalleled accuracy. This guide delves into the capabilities, applications, and benefits of the LaserHawk LH2, providing a detailed overview that will help you understand why it is a top choice for both professionals and hobbyists.

Understanding the Laser Engraving Process

Laser engraving is a process where a focused laser beam removes material to create an impression or design. This technique is widely used in various industries due to its precision and adaptability. The LaserHawk LH2 employs advanced laser cutting technology, making it suitable for a range of applications from industrial production to artistic projects.

How Laser Engraving Works

The process involves directing a high-powered laser at the material’s surface, vaporizing or melting it to create detailed engravings. Unlike traditional methods, laser engraving offers non-contact processing, reducing wear and tear on tools and enhancing longevity.

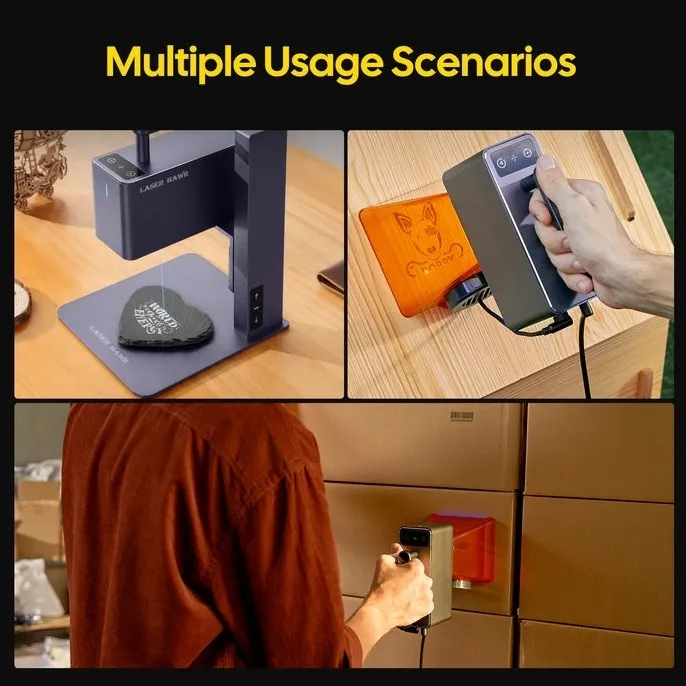

Applications of Laser Engraving

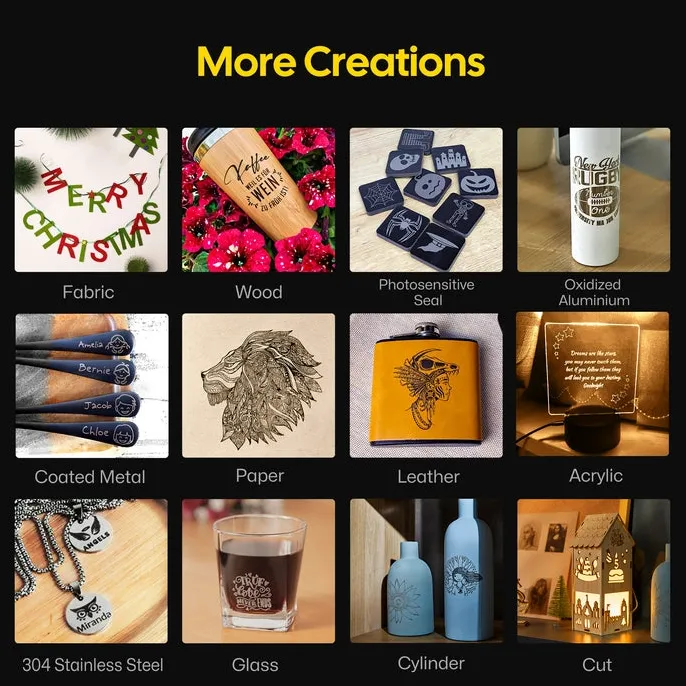

- Custom Design Work: Ideal for creating unique patterns on materials like wood, metal, and plastic.

- Industrial Marking: Used for serial numbers, barcodes, and logos on products.

- Artistic Expression: Perfect for artists to bring their visions to life with intricate details.

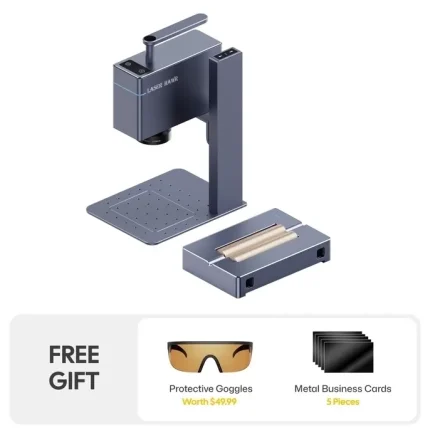

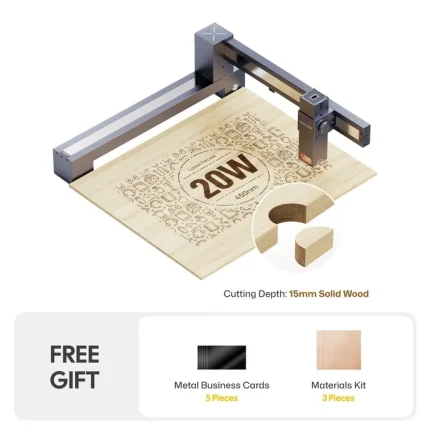

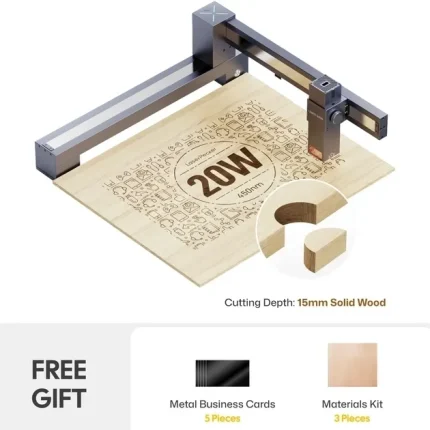

Technical Specifications of LaserHawk LH2

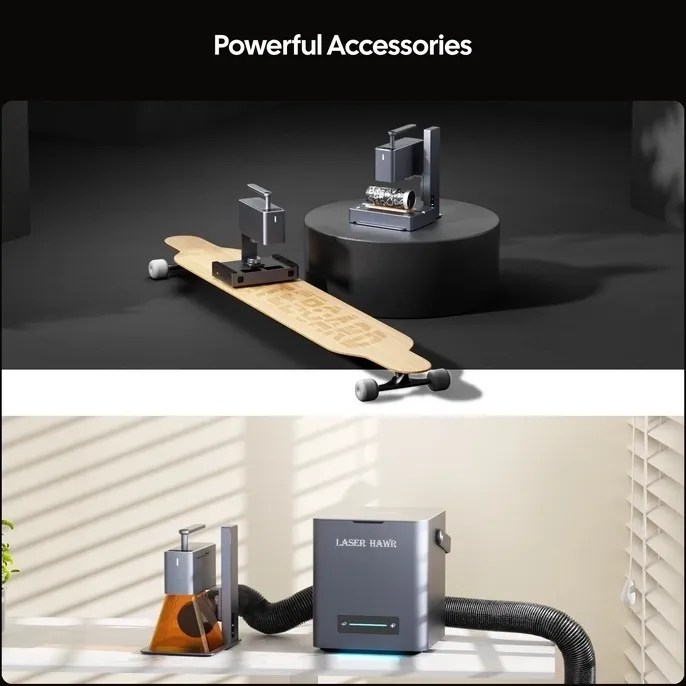

The LaserHawk LH2 is equipped with cutting-edge features designed for efficiency and precision. Here’s an overview of its technical specifications:

Key Features:

- Laser Power Output: 100W CO2 laser, capable of handling diverse materials.

- Build Quality: Robust construction ensuring durability and longevity.

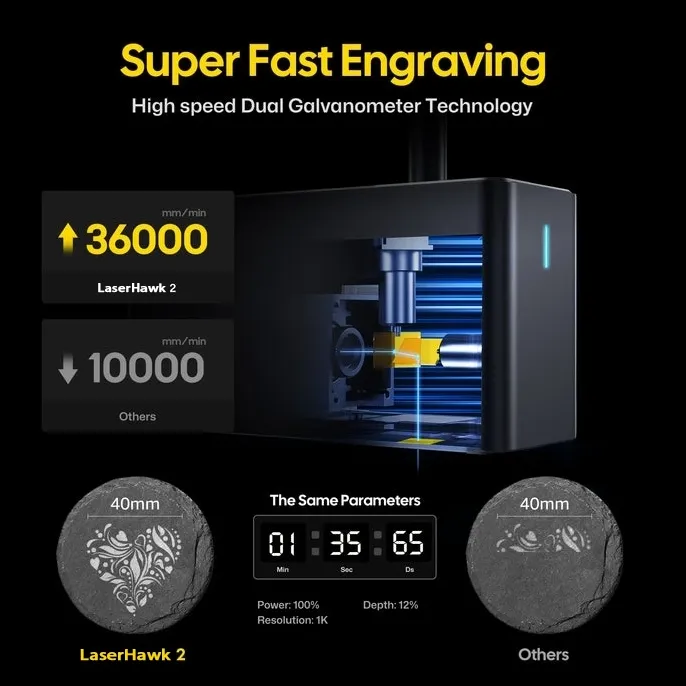

- Processing Speed: High-speed processing with customizable settings.

- Compatibility: Works seamlessly with various materials including wood, metal, acrylic, and glass.

- Design Features: Ergonomic design for easy operation and maintenance.

Advanced Capabilities:

- Software Integration: Compatible with popular CAD/CAM software for precise design control.

- Cooling System: Efficient cooling to maintain optimal performance during prolonged use.

- Safety Features: Equipped with emergency stop mechanisms and safety shields.

Advantages Over Traditional Methods

The LaserHawk LH2 offers several advantages over conventional engraving methods:

- Precision: Achieves intricate details that are difficult to replicate manually.

- Speed: Efficient processing reduces production time significantly.

- Versatility: Suitable for a wide range of materials, enhancing its application across industries.

Conclusion

The LaserHawk LH2 is a testament to the advancement in laser technology, providing an efficient and precise solution for engraving and cutting needs. Its versatility and robust design make it a valuable asset in various industrial and creative applications.

FAQ Section

-

What materials can be engraved with the LaserHawk LH2?

The LaserHawk LH2 supports a variety of materials including wood, metal, acrylic, and glass, offering flexibility across different projects. -

How does laser engraving compare to traditional methods?

Laser engraving offers higher precision, speed, and versatility compared to traditional methods, making it ideal for both small-scale and large-scale production. -

Is the LaserHawk LH2 suitable for artistic work?

Absolutely! Its high precision allows artists to create intricate designs, making it a favorite in creative projects. -

What safety features does the LaserHawk LH2 have?

The machine includes emergency stop mechanisms and safety shields to ensure safe operation. -

Can I customize the settings on the LaserHawk LH2?

Yes, the machine allows for customizable settings to accommodate different materials and project requirements, enhancing its adaptability.

This comprehensive guide provides insights into the capabilities of the LaserHawk LH2, helping you understand its role in modern engraving and cutting processes.

Young Fischer –

As a laser engraver user, I give this machine 5 stars! The engraving results are precise and stunning. The operation is smooth, software intuitive. Fast speeds boost efficiency. Solid build, reliable!

Isabella Anderson –

As a laser engraver user, I give this machine 5 stars. The engraving effects are precise, the operation smooth, software user-friendly. Fast speed boosts efficiency. Solid build, highly reliable!

Michael Bernard –

Absolutely outstanding! The laser engraver delivers precision results with flawless detail. The intuitive software and smooth operation make it a breeze to use. Fast engraving speeds boost productivity, and its solid build ensures reliability. 5 stars!

Richard Martinez –

This laser engraver delivers stunning detail and precision, with intuitive software and smooth operation. It’s fast, efficient, and built to last, earning it a well-deserved 5 stars.

Anders Fischer –

Absolutely stunning engraving results with pinpoint accuracy! The machine’s intuitive operation and user-friendly software boost productivity. Fast carving speed, solid build, and reliable performance make it a 5-star tool.

Nikolai Romano (verified owner) –

**Performance & User Experience Review:**

The 40W CO2 laser excels on wood and acrylic, delivering crisp 500 DPI engravings at 100mm/s. However, leather requires multiple passes for consistency. The autofocus system and rotary attachment simplified creating custom wine glasses and intricate wooden puzzles. The proprietary software’s layer-based workflow is intuitive but lacks advanced vector editing. While setup took <30 minutes, the cooling fan’s noise (65dB) is disruptive in home studios. A mobile app for project previews is a standout, though manual bed leveling remains finicky. Ideal for artisans needing precision without industrial price tags, but material presets need expansion.

Paul Li (verified owner) –

The laser engraver excels in Performance Analysis across various materials like wood, acrylic, and leather, delivering precise engravings with speed. Its standout User Experience includes an intuitive software interface and a helpful auto-focus feature. Compared to similar models, it offers superior precision and speed but lacks a longer warranty. Ideal for artistic and business applications, it handles intricate designs well, though a slightly larger workspace could enhance versatility. The price-performance ratio is favorable, with good ROI for businesses, yet minor tweaks like expanded instructions and a bigger workspace would further enhance its appeal.

Nancy Scott (verified owner) –

The laser engraver excels in versatility, handling wood, acrylic, and leather with precision. Its 10W power delivers crisp engravings on wood within seconds, while acrylic requires careful speed adjustments for optimal results. The software interface is intuitive, though a steeper learning curve applies for advanced features. Dual-axis control and auto-focusing are standout features, simplifying complex projects. Minor suggestion: additional nozzles for varied applications would enhance flexibility. Ideal for crafters and small businesses seeking high-quality engravings.

Klaus Hill (verified owner) –

The laser engraver excels in user experience with an intuitive software interface and a streamlined setup process, making it accessible even for newcomers. Its technical specs, including high power output and superior resolution, deliver crisp engravings on various materials. While the system is robust, enhancing cooling mechanisms would improve longevity during extended use. Minor dust control issues could be addressed with better ventilation options. Overall, its ease of use and precision make it a valuable tool for both hobbyists and professionals seeking reliable performance.

Dorothy Saito (verified owner) –

**Laser Engraver Review for Sign-Making Business**

**1. Specific Project Experience: Cultural Art Pieces**

– **Project Details:** Recently, I utilized the laser engraver on intricate cultural art pieces, focusing on wood and acrylic materials. The engravings were highly detailed, showcasing fine lines and textures that enhanced the artwork’s authenticity.

– **Material Behavior:** The laser handled different materials consistently well. Wood and acrylic produced clean, precise results with vibrant details. Metal initially posed a challenge due to uneven burns, but adjusting power levels and speed resolved this, yielding professional-quality engravings.

**2. Technical Performance: Power, Precision, and Software Features**

– **Power and Precision:** The laser’s consistent cutting and engraving capabilities ensured that even complex designs were executed flawlessly, reducing the need for post-engraving touch-ups.

– **Software Experience:** The user-friendly software included a preview feature, which was instrumental in avoiding errors. Additionally, the auto-focusing mechanism saved significant setup time, ensuring each project started with pinpoint accuracy.

**3. Business Impact: Workflow and Customer Satisfaction**

– **Workflow Improvement:** The laser engraver streamlined operations, allowing projects to be completed more efficiently than with previous tools like the CNC machine.

– **Customer Feedback:** Clients have praised the quality and detail of the work, leading to increased repeat business and referrals.

– **Return on Investment (ROI):** Despite the initial cost, the tool’s versatility and efficiency have significantly boosted productivity, enabling the handling of more complex projects and thus enhancing revenue.

**4. Comparison & Value: Versus Previous Tools**

– **Versatility and Efficiency:** Compared to the old CNC machine, the laser engraver offers greater speed and precision across various materials.

– **Cost-Effectiveness:** While the upfront investment was substantial, the long-term benefits in time savings and project capabilities justify the expense, making it a valuable asset for the business.

This review highlights how the laser engraver has not only enhanced creative output but also improved operational efficiency and customer satisfaction, proving to be a worthwhile investment.

James Mitchell (verified owner) –

The LaserHawk LH2 has been an absolute game-changer for my jewelry projects! The precision and ease of use make creating intricate designs effortless, and knowing it comes with a solid year warranty gives me peace of mind.

Pierre Lee –

As a laser engraver user, I give this machine 5 stars. The engraving effects and precision are top-notch. Operation and software are user-friendly. Fast engraving speed boosts overall efficiency. Well-built and reliable.