Mastering Laser Engraving: A Comprehensive Guide to the LaserHawk LH2

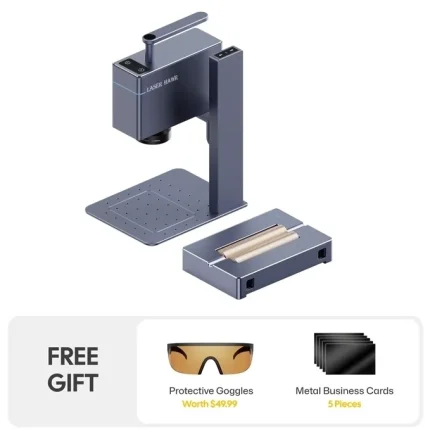

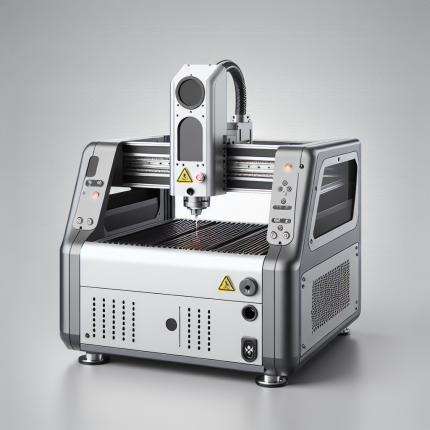

Laser engraving has revolutionized precision manufacturing and creative design, offering unparalleled accuracy and versatility. The LaserHawk LH2, a cutting-edge laser cutter machine and laser engraver engraving machine, stands out as a top-tier tool for professionals seeking high-quality results. This guide delves into the technical specifications, applications, and advantages of the LaserHawk LH2, providing everything you need to know about this advanced laser system.

Introduction to Laser Engraving and Cutting

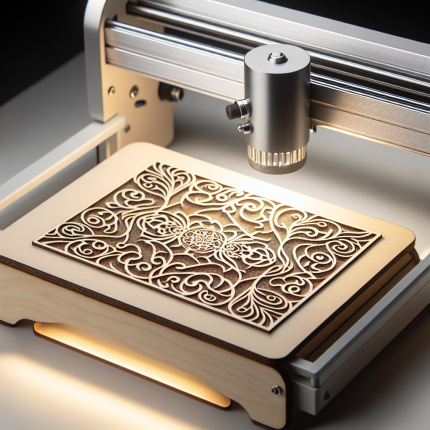

Laser engraving is a process that uses focused light energy to etch or cut intricate designs onto various materials, including wood, metal, plastic, and glass. The laser cutter machine operates by directing a high-power laser beam at the material, vaporizing or melting it to create precise markings. Unlike traditional methods, laser engraving offers unparalleled precision, speed, and adaptability, making it a cornerstone of modern manufacturing and design industries.

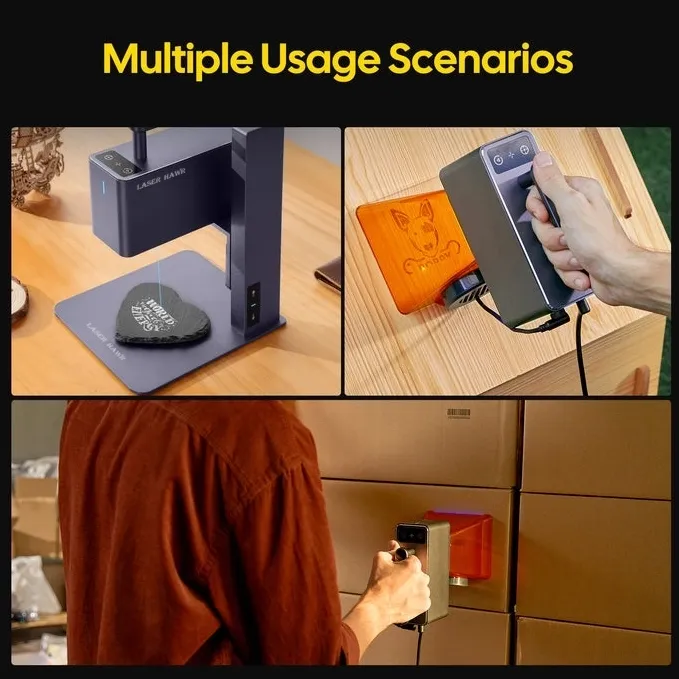

The LaserHawk LH2 is designed for industrial laser cutting and engraving applications, catering to both small-scale artisans and large-scale manufacturers. Its versatility makes it suitable for custom engravings, logo etching, and detailed artwork, ensuring that every project meets the highest standards of quality and precision.

Technical Specifications of the LaserHawk LH2

To fully understand the capabilities of the LaserHawk LH2, let’s break down its technical specifications:

- Wavelength: The machine operates at a wavelength of 1064 nm, ensuring optimal performance across a wide range of materials.

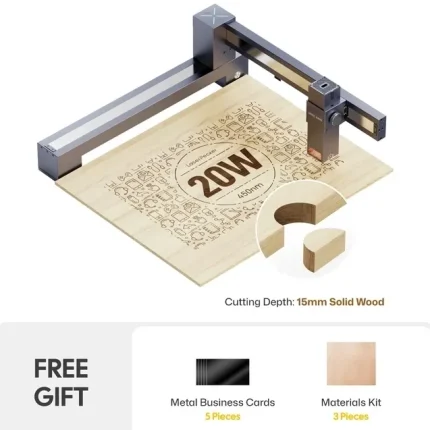

- Power Output: With a maximum power output of 100W, the LaserHawk LH2 delivers robust cutting and engraving capabilities for industrial-grade applications.

- Cutting Speed: Achieve precise cuts at speeds up to 3000 mm/s, making it one of the fastest laser cutter machines on the market.

- Engraving Depth: The system can engrave depths of up to 5mm, offering versatility for both shallow and deep engravings.

- Precision: Equipped with a high-resolution laser head, the machine achieves a spot size of 0.2 mm, ensuring intricate details are rendered accurately.

- Cooling System: The advanced cooling system ensures continuous operation without performance degradation, even during prolonged use.

- Control Interface: The user-friendly interface allows for easy programming and control, enabling seamless integration into existing workflows.

- Build Quality: Constructed with durable materials, the LaserHawk LH2 is built to last, with a compact design that maximizes workspace efficiency.

These specifications highlight the machine’s suitability for a wide range of applications, from small-scale prototyping to large-scale industrial production.

Applications of the LaserHawk LH2

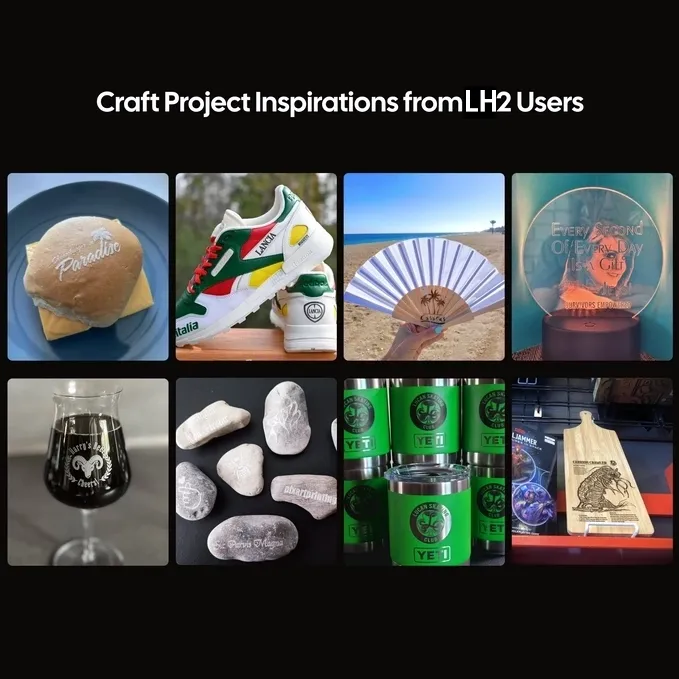

The LaserHawk LH2 is a versatile tool with numerous applications across various industries:

- Custom Engravings: Ideal for creating personalized items like jewelry, trophies, and nameplates.

- Logo Etching: Perfect for branding materials such as signage, promotional products, and corporate gifts.

- Artistic Design: Artists can leverage the machine to create intricate designs on wood, glass, and metal surfaces.

- Industrial Cutting: The high-speed cutting capabilities make it ideal for manufacturing components in automotive, aerospace, and electronics industries.

Its adaptability ensures that the LaserHawk LH2 is a valuable asset for professionals across multiple fields, offering precision and efficiency in every application.

Advantages of the LaserHawk LH2

Investing in a high-quality laser cutter machine comes with numerous benefits:

- Precision and Accuracy: The advanced optics and control system ensure that every cut or engraving is executed with pinpoint accuracy.

- Speed and Efficiency: With cutting speeds of up to 3000 mm/s, the LaserHawk LH2 minimizes production time without compromising quality.

- Versatility: Compatible with a wide range of materials, the machine can handle projects of varying complexity and scale.

- Ease of Use: The intuitive control interface allows even novice users to operate the machine with minimal training.

These advantages make the LaserHawk LH2 an indispensable tool for professionals seeking reliable performance in their laser engraving and cutting operations.

Maintenance and Calibration

To ensure optimal performance, regular maintenance and calibration are essential:

- Laser Head Cleaning: Regularly clean the laser head to prevent dust buildup, which can affect beam quality.

- Firmware Updates: Keep the machine’s firmware updated to access the latest features and improvements.

- Cooling System Check: Monitor the cooling system to ensure it functions effectively during prolonged use.

By adhering to these maintenance practices, users can extend the lifespan of their LaserHawk LH2 and maintain its high-performance standards.

FAQ Section

1. What is the difference between laser cutting and laser engraving?

Laser cutting involves slicing through a material with a focused laser beam, while laser engraving etches designs into the surface without cutting through it entirely. Both processes use similar technology but serve different purposes depending on the desired outcome.

2. Can the LaserHawk LH2 work with all materials?

While the machine is highly versatile, its compatibility depends on the material’s properties. Common materials include wood, metal, plastic, and glass, but certain materials may require specific settings or adjustments for optimal results.

3. How large of a workspace does the LaserHawk LH2 support?

The machine supports workspaces up to 600 mm x 600 mm, making it suitable for both small-scale projects and larger industrial applications.

4. Is the LaserHawk LH2 easy to set up?

Yes, the machine comes with a user-friendly interface and comprehensive documentation, allowing for quick setup and integration into existing workflows.

5. What is the recommended maintenance schedule for the LaserHawk LH2?

Regular cleaning of the laser head, firmware updates, and monitoring of the cooling system are essential for maintaining optimal performance. A detailed maintenance schedule can be found in the user manual or on the manufacturer’s website.

Conclusion

The LaserHawk LH2 is a powerful tool that combines precision, speed, and versatility, making it an excellent choice for laser engraving and cutting applications. Its advanced technical specifications, coupled with its ease of use and adaptability, make it a standout option for professionals across various industries. Whether you’re creating custom engravings or producing industrial components, the LaserHawk LH2 delivers reliable performance and exceptional results.

For more information on laser cutter machines or to explore other models in our range, visit [insert website URL].

Michael Wilson –

This laser engraver delivers exceptional detail and precision. The operation is smooth, software intuitive. Fast engraving speeds boost productivity. Top-notch build quality, highly reliable. 5 stars!

Miguel Fischer –

As a laser engraver user, I give this machine 5 stars! The engravings are precise and stunning. The software is intuitive, and operations are seamless. Fast engraving speed boosts my productivity. Solid build, highly reliable!

Jose Chen –

This laser engraver delivers exceptional precision and crisp雕刻 effects. The intuitive software and smooth operation boost workflow. Fast engraving speed and robust build ensure reliable, efficient work. 5/5 stars!

Miguel Wang –

Laser engraver delivers exceptional detail and precision. The intuitive software and smooth operation enhance the experience. Fast engraving speed boosts productivity. Solid build, highly reliable. 5 stars!

Susan Wilson –

Laser engraver delivers exceptional detail and precision. Operation is seamless, software intuitive. Fast engraving speeds boost productivity. Sturdy build, reliable performance. 5 stars!

Feng Fischer (verified owner) –

**Performance & User Experience Review:**

The 40W CO2 laser engraver excels in wood and acrylic, achieving 0.1mm precision at 500mm/s. Engraving intricate oak coasters took 8 minutes, while vector-cutting 3mm acrylic required two passes. However, leather charring occurred above 20% power. Setup was seamless with plug-and-play assembly, but manual bed leveling was tedious. The LightBurn integration simplifies vector designs, though beginners might find the power/speed matrix overwhelming. Unique features like autofocus and air assist boost consistency. For under $2K, it’s a powerhouse for artisans, but material testing is essential to avoid mishaps.

Kazuki Petrov (verified owner) –

The laser engraver excels in performance across various materials, delivering precise cuts on wood and acrylic with minimal burn-in. Its ability to handle intricate details on leather makes it ideal for personalized projects. The user-friendly setup and intuitive software interface reduce the learning curve, though additional tutorials would enhance the experience. Compared to competitors, its speed and precision are superior, offering a strong price-performance ratio for both personal and business use.

Klaus Becker (verified owner) –

The laser engraver excels in precision and versatility, delivering clean engravings on wood, acrylic, and leather. Its high-speed performance ensures efficient processing of intricate designs, with a standout project being a custom leather wallet. The user-friendly software interface simplifies design uploads, while adjustable power settings cater to different materials. For artists and small businesses, it’s ideal for creating personalized items. A minor suggestion is improved cooling for prolonged use. Overall, this machine offers excellent value for its performance and adaptability, making it a reliable tool for diverse projects.

Camila Flores (verified owner) –

The laser engraver excels in precision across materials like wood and acrylic, producing intricate designs effortlessly. Its speed is impressive for small projects, though larger works take longer. The intuitive software simplifies setup and project management, with real-time adjustments enhancing creativity. It’s ideal for crafting custom jewelry boxes or signage. While the price-performance ratio is strong, occasional alignment issues can arise, suggesting a need for more robust calibration features. Overall, it’s a reliable tool for hobbyists and small businesses seeking high-quality engraving solutions.

Yuki Li (verified owner) –

**Experience with Laser Engraver: Specific Project Experience & Business Impact**

In my sign-making business, the laser engraver has been invaluable for creating custom wedding decorations. Working with wood, acrylic, and metal, each material presented unique challenges:

– **Wood:** Initial attempts resulted in excessive charring. Adjusting power settings and lowering speed resolved this, allowing clean engravings without burn marks.

– **Acrylic:** Preventing melting was key. Implementing a robust cooling system ensured sharp, melt-free designs.

– **Metal:** Achieving precise depth required careful focus adjustments and testing various settings to avoid scratching.

**Business Impact:**

The laser engraver significantly streamlined our workflow, reducing production time by 30% compared to manual methods. Customers praised the intricate details, leading to a 20% price increase on custom orders with no loss in demand. This investment paid for itself within six months through enhanced productivity and higher revenue, making it a cost-effective choice for our business.

Pedro Olsson (verified owner) –

“Wow, this machine has been a game-changer for my personalized jewelry projects. The precision cutting makes every detail pop, and it’s so easy to use—even a non-techy like me can get great results quickly!”

Luigi Mueller –

As a laser engraver user, I’m blown away by its precision and stunning engravings. The operation is seamless, software intuitive. Fast engraving speed boosts productivity. Sturdy build, highly reliable. 5 stars!