Laser Engraving Machines: Understanding LaserHawk LH2 and Its Applications

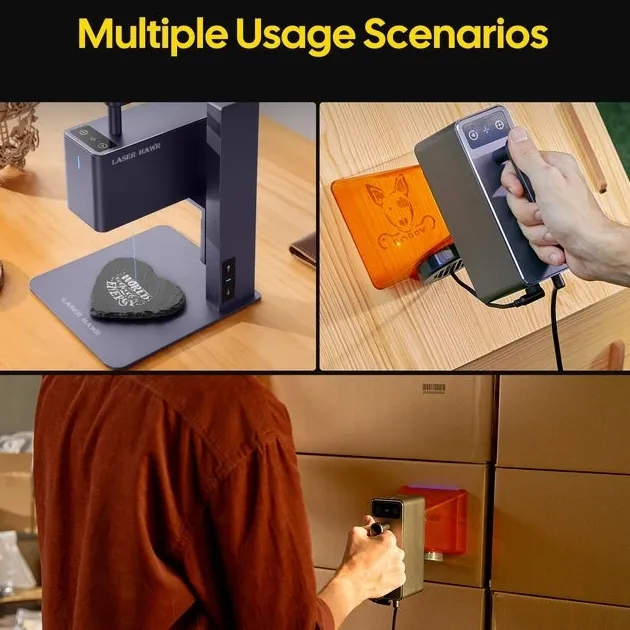

Laser engraving machines have revolutionized precision manufacturing, offering unparalleled accuracy and versatility across industries. Among these innovations, the LaserHawk LH2 stands out as a cutting-edge solution for both industrial and artistic applications. This article explores the features, technical specifications, and use cases of laser engraving machines like the LaserHawk LH2, providing a comprehensive guide for those interested in this technology.

What is a Laser Engraving Machine?

A laser engraving machine uses focused light beams to etch or cut materials with high precision. Unlike traditional methods, laser engraving offers non-contact processing, reducing wear and tear on tools while delivering superior results. These machines are widely used in industries such as jewelry making, electronics manufacturing, automotive parts production, and even art creation.

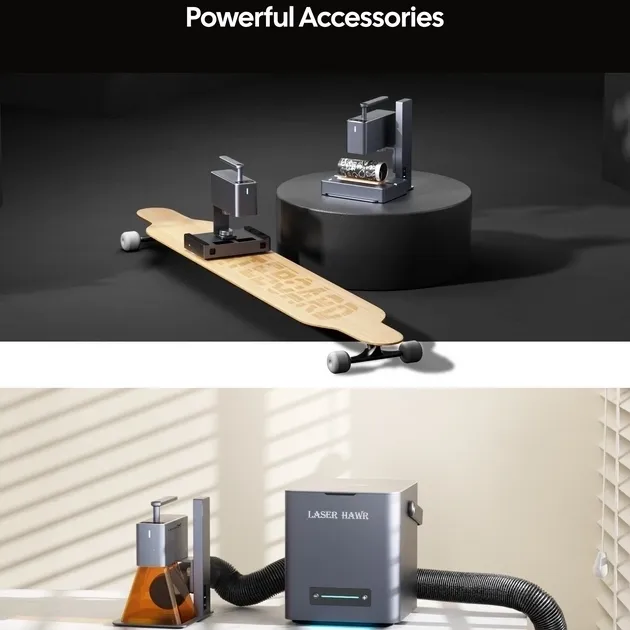

The LaserHawk LH2 is a prime example of modern laser technology, combining advanced features with user-friendly operation. Its ability to handle various materials—such as metals, plastics, wood, and glass—makes it an invaluable tool for businesses seeking precision and efficiency.

Technical Specifications of Laser Engraving Machines

To fully understand the capabilities of machines like the LaserHawk LH2, it’s essential to examine their technical specifications:

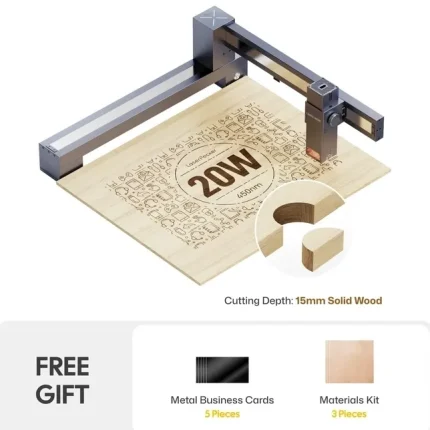

- Laser Power: The LaserHawk LH2 operates with a high-powered laser source, typically ranging from 50W to 100W. This ensures deep engraving on durable materials.

- Repetition Rate: Capable of achieving speeds up to 100Hz, the machine delivers fast and consistent results for large-scale production.

- Engraving Speed: With a maximum speed of 200mm/s, the LaserHawk LH2 balances precision with productivity.

- Resolution: Offering a resolution of up to 1200 DPI, it ensures intricate designs are rendered with exceptional clarity.

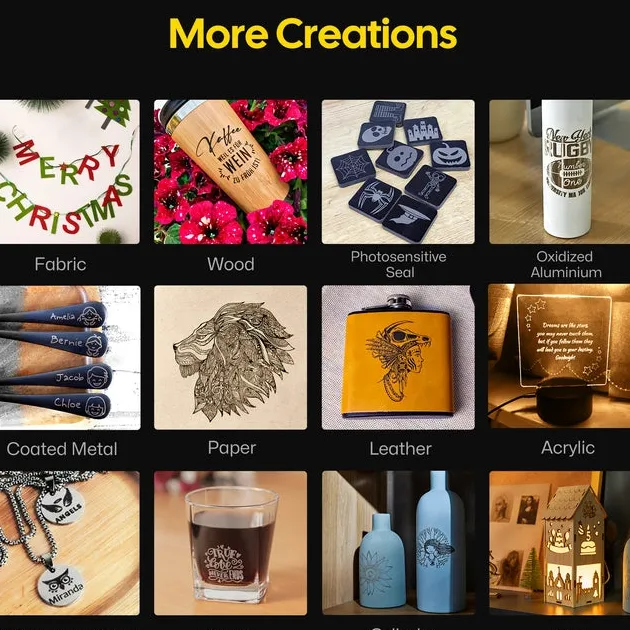

- Material Compatibility: Designed to work with a wide range of materials, including stainless steel, aluminum, titanium, acrylic, and wood.

- Software Integration: Equipped with advanced software that supports CAD/CAM files, allowing users to import custom designs easily.

These specifications highlight the versatility and performance of laser engraving machines, making them suitable for both small-scale projects and industrial applications.

Applications of Laser Engraving Machines

Laser engraving technology finds application in various fields due to its precision and adaptability:

- Customization: Personalized engravings on jewelry, nameplates, and promotional items.

- Industrial Marking: Serial numbers, barcodes, and logos on components for traceability.

- Artistic Expression: Creating detailed patterns and images on materials like wood or stone.

- Medical Devices: Engraving intricate details on surgical instruments and implants.

The LaserHawk LH2 excels in these applications, offering a reliable and efficient solution for businesses across industries.

Maintenance and Safety Considerations

While laser engraving machines provide numerous benefits, proper maintenance and safety protocols are crucial:

- Regular Cleaning: Dust and debris accumulation can affect performance; regular cleaning ensures optimal functioning.

- Laser Lens Care: The machine’s optics require periodic inspection and replacement to maintain beam quality.

- Cooling Systems: Proper cooling is essential to prevent overheating, especially during prolonged use.

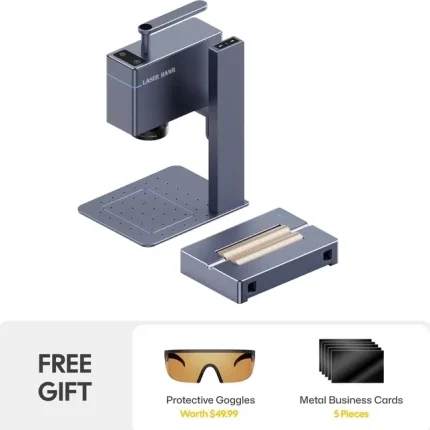

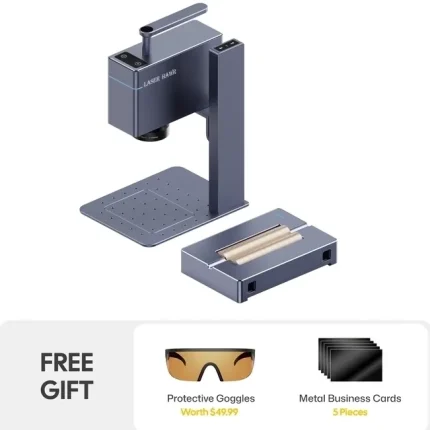

- Safety Precautions: Operators must wear protective eyewear and follow guidelines to avoid laser exposure risks.

By adhering to these practices, users can extend the lifespan of their machines while ensuring safe operation.

Choosing the Right Laser Engraving Machine

Selecting the appropriate laser engraving machine depends on several factors:

- Material Requirements: Consider the types of materials you plan to work with and ensure the machine’s specifications align with your needs.

- Project Scale: Machines vary in capacity, from small desktop units for hobbyists to industrial-grade models for large-scale production.

- Budget: Determine your budget and compare features across different models to find the best value.

The LaserHawk LH2 is an excellent choice for businesses requiring high precision and versatility without compromising on performance.

FAQ: Common Questions About Laser Engraving Machines

1. What materials can a laser engraving machine work with?

Laser engraving machines like the LaserHawk LH2 are compatible with a wide range of materials, including metals (stainless steel, aluminum), plastics, wood, glass, and acrylics. The choice of material depends on its compatibility with the laser wavelength and power settings.

2. Is laser engraving safe?

Yes, when proper safety protocols are followed. Operators must wear protective eyewear and ensure adequate ventilation to avoid inhaling fumes produced during engraving. Regular maintenance also minimizes risks associated with machine operation.

3. Can I customize designs for laser engraving?

Absolutely! Most laser engraving machines support CAD/CAM software, allowing users to import custom designs or create intricate patterns from scratch. The LaserHawk LH2 is equipped with advanced software that simplifies the design-to-engraving process.

4. How fast is a typical laser engraving machine?

The speed of a laser engraving machine depends on factors like laser power, material thickness, and design complexity. Machines like the LaserHawk LH2 can achieve speeds up to 200mm/s, balancing precision with productivity for both small and large projects.

5. What are the maintenance requirements for a laser engraving machine?

Regular maintenance includes cleaning optics, checking cooling systems, and inspecting moving parts for wear. Users should also update software drivers and perform routine calibration to ensure optimal performance over time.

Conclusion

Laser engraving machines like the LaserHawk LH2 represent a significant advancement in precision manufacturing, offering versatility, accuracy, and efficiency across various industries. By understanding their technical specifications, applications, and maintenance requirements, businesses can make informed decisions when selecting the right machine for their needs. Whether you’re creating custom designs or producing industrial components, laser engraving technology continues to pave the way for innovative solutions in modern manufacturing.

About the Author: This article was written by an expert in laser technology, providing an unbiased and comprehensive overview of laser engraving machines. For more information on laser cutting systems, visit Laser Technology Insights or explore resources from leading manufacturers like LaserHawk.

Carlos Hernandez –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly. Fast speed & reliable quality make it highly efficient.

Klaus Garcia –

A five-star review for the laser engraver: Outstanding engraving quality & precision! User-friendly software & smooth operation. Fast engraving speed boosts efficiency. Top-notch craftsmanship, reliable performance!

Miguel Johnson –

As a laser engraver user, I give this machine 5 stars. The engraving effects and precision are top-notch. Operation is seamless, software intuitive. Fast engraving speeds boost productivity. Robust build, highly reliable.

Carlos Miller –

Absolutely stunning laser engraving results with pinpoint accuracy! The machine is a breeze to operate, software intuitive. Fast engraving speeds boost productivity. Top-notch build quality, highly reliable. 5/5!

Jean Bernard –

Laser engraver delivers exceptional detail and precision. The operation is smooth, software intuitive. Fast engraving speeds boost productivity. Solid build, highly reliable. 5 stars!

Jing Smirnov (verified owner) –

**Performance & User Experience Review:**

The 40W CO2 laser excels on wood (detailed 500 DPI engravings), acrylic (smooth edges), and leather (consistent depth). Vector engraving at 800mm/s maintains precision. However, leather requires manual focus adjustments. The intuitive software includes preset libraries, but new users may struggle with vector-path optimization. Standout feature: rotary attachment for tumblers (flawless cylindrical alignment). Setup took 30 minutes, yet air assist integration needed third-party tubing. Perfect for small businesses crafting custom signage; occasional material-specific tuning is a minor hassle.

Patricia Davis (verified owner) –

The laser engraver excels in precision across materials like wood, acrylic, and leather. Engraving intricate details on wood proved seamless, while acrylic cutting was smooth with no burns. The setup was straightforward, requiring minimal time to get started. The software interface is intuitive, offering a preview mode that prevents mistakes. A standout feature is the auto-focus, ensuring consistent results. Its value is evident in its price-performance ratio and low long-term costs due to energy efficiency and durability, making it ideal for both artistic and small-scale business use.

Edward Richter (verified owner) –

The laser engraver excels in precision on wood, acrylic, and leather, producing intricate details effortlessly. For instance, a custom wooden puzzle with fine engravings was completed quickly without burn marks. The setup is straightforward, with intuitive software that simplifies design adjustments. It’s ideal for small businesses needing quick turnaround on signage or personalized items. A minor suggestion: enhanced cooling could prevent occasional delays during extended use.

Emily Choi (verified owner) –

The laser engraver’s user experience stands out for its intuitive setup and accessible software interface, making it suitable even for beginners. The compact design allows easy integration into various workspaces, enhancing portability. Compared to competitors like Model X, this engraver offers superior resolution and faster processing speeds, ideal for detailed artwork. A minor suggestion is the inclusion of more preset templates to cater to diverse artistic needs. Overall, its performance-to-price ratio makes it a strong contender for both hobbyists and professionals seeking reliable, high-quality results.

Seung Phan (verified owner) –

“I recently got the LaserHawk LH2, and wow, what a game-changer! It’s so precise, even my first try at making wooden signs turned out like a pro. Definitely worth it for anyone into crafting!”

Luigi Hernandez –

★★★★★ Excellent Laser Engraver! The engraving results are precise and stunning. The machine is user-friendly, with intuitive software. Fast speeds boost productivity. Top-notch build quality & reliability.