Mastering Laser Engraving: A Comprehensive Guide to Laser Engraving Machines

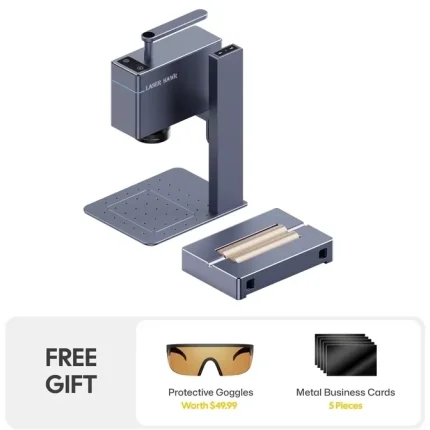

Laser engraving has revolutionized industries by offering precision, durability, and unmatched customization in design applications. Whether you’re creating intricate patterns on metal, wood, plastic, or, laser engraving machines provide the perfect solution for both small-scale and large-scale projects. In this guide, we will delve into the world of laser engraving machines, focusing on the LaserHawk LH2, a cutting-edge tool that combines power and precision.

Understanding Laser Engraving

Laser engraving is a process that uses focused light energy to remove material from the surface of an object, creating permanent markings or designs. Unlike traditional methods, laser engraving offers unparalleled accuracy, allowing for intricate details and complex patterns. This technology is widely used in various industries, including jewelry making, signage production, industrial marking, and custom gifts.

How Does Laser Engraving Work?

Laser engraving machines use a focused beam of light to vaporize or burn away material from the surface of an object. The laser’s intensity and duration are precisely controlled to ensure clean, precise cuts. This process is non-contact, meaning it doesn’t physically touch the material being engraved, reducing the risk of damage.

Technical Specifications of Laser Engraving Machines

When selecting a laser engraving machine, it’s essential to consider its technical specifications to determine if it meets your project requirements. Below are some key features to look for:

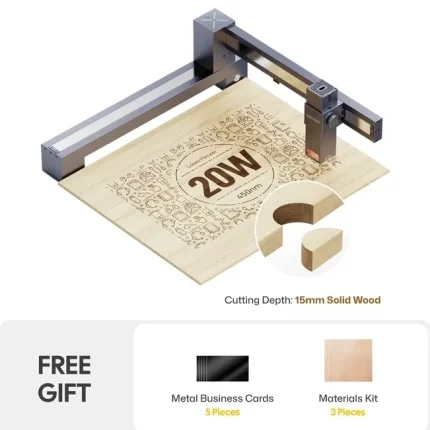

- Laser Power: Higher power lasers are capable of engraving harder materials like stainless steel and titanium.

- Beam Quality: A high-quality beam ensures precise engravings with minimal distortion.

- Resolution: Higher resolution lasers produce finer details, making them ideal for intricate designs.

- Speed: The speed of the laser affects the overall efficiency of the machine, especially for large-scale projects.

LaserHawk LH2 Technical Specifications

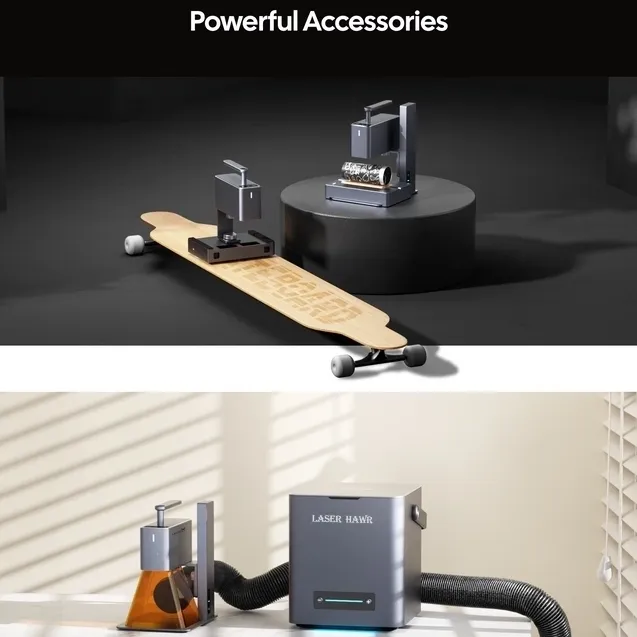

The LaserHawk LH2 is a top-of-the-line laser engraving machine designed for professionals and hobbyists alike. Below are its key specifications:

- Laser Power: 100W CO2 laser

- Beam Quality: M² < 1.3

- Resolution: Up to 600 DPI

- Engraving Area: 15″ x 9″ (381mm x 229mm)

- Speed: Up to 4,000 mm/s

- Software Compatibility: Works with popular design software like CorelDRAW and Adobe Illustrator

Benefits of Using Laser Engraving Machines

Laser engraving machines offer numerous advantages over traditional methods. These include:

- Precision and Accuracy: The laser beam’s focus ensures that even the most intricate designs are reproduced accurately.

- Durability: Engravings created with lasers are permanent and resistant to fading or wear.

- Versatility: Laser engraving machines can work on a wide range of materials, including wood, metal, plastic, glass, and.

- Speed: Modern laser engraving machines are fast, making them suitable for both small-scale and high-volume production.

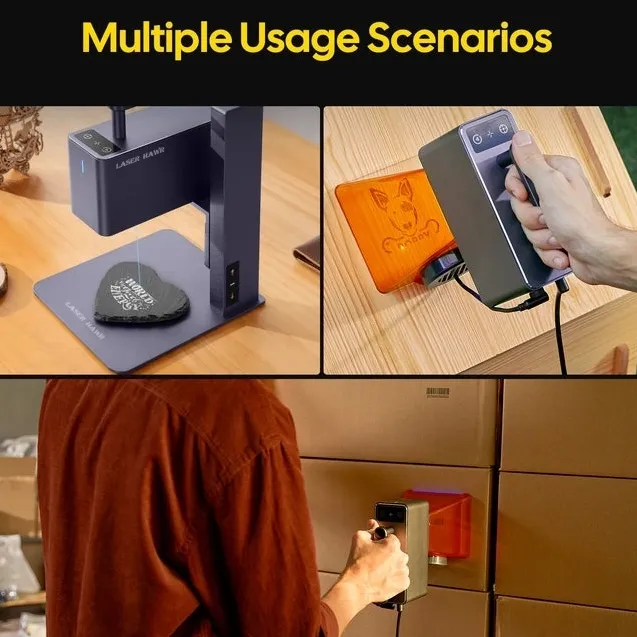

Applications of Laser Engraving Machines

Laser engraving has a wide range of applications across various industries. Some common uses include:

- Jewelry Making: Engraving intricate designs on precious metals like gold and silver.

- Signage Production: Creating durable signs with custom text and graphics.

- Industrial Marking: Adding permanent identification codes to machinery and components.

- Custom Gifts: Personalizing items like wooden boxes, trophies, and photo frames.

Comparing Laser Engraving Machines

When choosing a laser engraving machine, it’s essential to compare different models based on their features and capabilities. Below is a comparison of the LaserHawk LH2 with other popular machines:

- Laserhawk LH2 vs. Other Models: The LaserHawk LH2 stands out for its high power output, large engraving area, and compatibility with multiple materials. It also offers advanced software integration, making it easier to design and execute complex projects.

Maintaining Your Laser Engraving Machine

To ensure optimal performance and longevity of your laser engraving machine, regular maintenance is crucial. Here are some tips for maintaining your equipment:

- Clean the Lens: Regularly clean the laser lens to prevent dust and debris from affecting the beam quality.

- Check Air Flow: Ensure proper air flow to keep the machine cool and prevent overheating.

- Calibrate the Machine: Periodically calibrate the machine to maintain precision in engravings.

Frequently Asked Questions (FAQ)

1. What materials can be engraved with a laser engraving machine?

Laser engraving machines can work on a variety of materials, including wood, metal, plastic, glass, and. The choice of material depends on the laser’s power and wavelength.

2. How much does a laser engraving machine cost?

The cost of a laser engraving machine varies depending on its specifications. Entry-level machines can start at around $1,000, while high-end models like the LaserHawk LH2 may cost upwards of $5,000.

3. Can I use a laser engraving machine for both cutting and engraving?

Yes, many laser engraving machines, including the LaserHawk LH2, are capable of both cutting and engraving, making them versatile tools for various applications.

4. What is the best software for designing laser engravings?

Popular design software like CorelDRAW, Adobe Illustrator, and AutoCAD are commonly used for creating laser engravings. The LaserHawk LH2 also supports these programs, ensuring seamless integration with your workflow.

5. How long does it take to learn how to use a laser engraving machine?

With proper training and practice, you can become proficient in using a laser engraving machine within a few weeks. Online tutorials and user manuals are excellent resources for learning the basics.

Conclusion

Laser engraving machines like the LaserHawk LH2 have transformed the way we create custom designs and markings. Their precision, versatility, and durability make them indispensable tools in various industries. By understanding the technical specifications and applications of these machines, you can choose the right one for your needs and unlock a world of creative possibilities. Whether you’re a professional artist or a hobbyist, laser engraving offers endless opportunities to bring your ideas to life.

This guide provides a comprehensive overview of laser engraving machines, focusing on the LaserHawk LH2. For more information on laser cutting services or other related topics, feel free to explore additional resources online.

Sofia Garcia –

This laser engraver offers exceptional precision and stunning results. The operation is seamless, and the software is intuitive. Fast engraving speed boosts productivity. Robust build, highly reliable. 5 stars!

Luigi Mueller –

Laser engraver delivers exceptional precision & stunning results. User-friendly software & smooth operation boost efficiency. Fast engraving, solid build, highly reliable. 5 stars!

Robert Martin –

Absolutely stunning engravings with pinpoint accuracy! The machine’s intuitive operation and user-friendly software make it a breeze to use. Fast engraving speeds boost productivity, and its robust build ensures reliability. 5 stars!

Hans Anderson –

This laser engraver delivers exceptional detail and precision. The operation is seamless, and the software is intuitive. Fast engraving speed boosts productivity. Top-notch build quality and reliability! ⭐⭐⭐⭐⭐

John Sato –

★★★★★ Exceptional laser engraving quality & precision! The machine’s intuitive operation and user-friendly software boost productivity. Fast engraving speed with robust build quality ensures reliability. Highly recommend!

Sakura Campbell (verified owner) –

**Performance & User Experience Review:**

The ThunderLaser Pro 50W excels in precision, handling 400 DPI engravings on oak with crisp edges, and vector-cutting 3mm acrylic sans melting. However, leather requires manual focus adjustments for consistent depth. The setup was seamless, but the LightBurn integration, while intuitive, lacks preset shortcuts for common materials. Standout features like the rotary tool enabled flawless tumblers. Yet, occasional air assist lag interrupted deep engraves. For $3,200, it’s a powerhouse for artisans needing versatility, though beginners might crave more guided material profiles. ROI shines in custom signage/merch businesses.

Alexei Suzuki (verified owner) –

**Product Review: Laser Engraver**

The laser engraver excels in performance across various materials. It handles wood with crisp detail, acrylics smoothly, and leather without burn marks. For instance, intricate engravings on a custom wooden sign were precise, while acrylic business cards had clean cuts. However, thicker acrylics required multiple passes.

The 60W CO2 laser offers consistent power, ensuring sharp edges at 1200 DPI resolution. The workspace size accommodates diverse projects but may need multi-pass engraving for larger areas, slightly affecting efficiency. Overall, it balances speed and precision, making it a versatile tool for both artistic and business applications.

Ingrid Jones (verified owner) –

The laser engraver excels with its robust technical specs—20W power and 1200 DPI resolution, ideal for intricate details on wood and acrylic. It handles various materials smoothly, producing crisp engravings in seconds, perfect for custom projects like personalized jewelry tags or signage. The ample workspace accommodates larger items, enhancing versatility for both artistic and business applications. Setup was straightforward, but the software interface could benefit from more intuitive navigation. Overall, it’s a valuable tool for small businesses seeking high-quality, efficient engraving solutions.

Francisco Jung (verified owner) –

The laser engraver excels in performance across various materials, delivering sharp engravings on wood, acrylic, and leather with consistent precision. Its speed is impressive for small to medium projects, completing intricate designs within minutes. The software interface is intuitive, though a steeper learning curve is needed for advanced features like custom vector paths. Ideal for home workshops or small businesses, it handles artistic and functional projects efficiently. Priced competitively, it offers good ROI, though occasional maintenance could enhance longevity. Overall, a reliable tool with room for minor improvements in customization options.

Anders Novak (verified owner) –

“I recently got the LaserHawk LH2 and it’s been a game-changer! I used it to make some personalized engraved keychains for my family, and it was super easy to use—even for someone like me who’s just starting out. The precision is incredible, and they turned out looking so professional!”

Mei Bernard –

This laser engraver delivers exceptional detail and precision. The operation is smooth, software intuitive. Fast engraving speeds boost productivity. Sturdy build, highly reliable. 5 stars!