The Ultimate Guide to Laser Engraving and Cutting Machines: Exploring the LaserHawk LH2

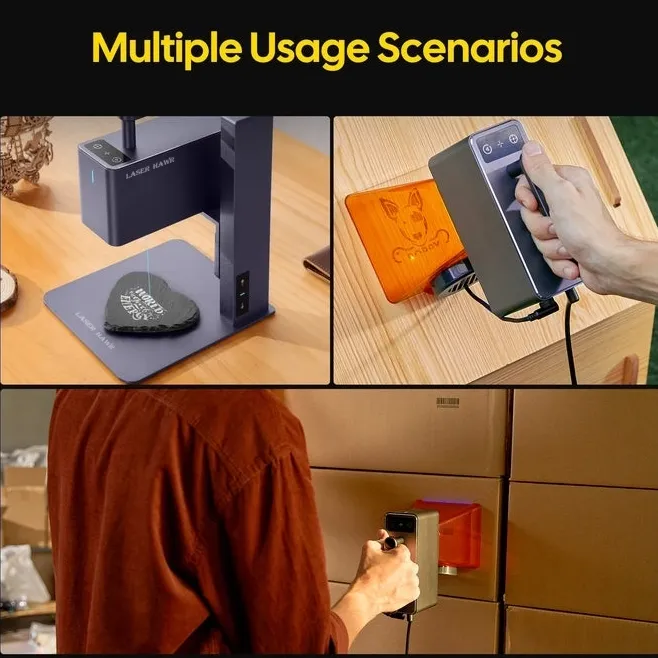

Laser engraving and cutting machines have revolutionized industries ranging from manufacturing to creative arts. These advanced tools offer precision, versatility, and efficiency, making them indispensable for businesses and hobbyists alike. Among the standout models in this field is the LaserHawk LH2, a high-performance laser engraver that combines cutting-edge technology with user-friendly design. In this comprehensive guide, we will explore everything you need to know about laser engraving machines, their applications, and the technical specifications of the LaserHawk LH2.

What Is a Laser Engraving Machine?

A laser engraving machine uses focused laser beams to etch or cut materials with exceptional precision. Unlike traditional methods, laser engraving is non-contact, which minimizes the risk of damaging delicate surfaces. These machines are widely used in industries such as jewelry making, electronics manufacturing, signage production, and custom.

How Does a Laser Engraving Machine Work?

The process involves directing a high-powered laser beam through a focusing lens to create precise patterns or cuts on the material’s surface. The intensity and duration of the laser can be adjusted depending on the desired outcome—whether it’s engraving fine details or cutting through thick materials.

Technical Specifications of the LaserHawk LH2

The LaserHawk LH2 stands out for its robust build and advanced features, making it a favorite among professionals. Below are some key technical specifications:

- Maximum Power Output: 100W

- Working Area Size: 300mm x 300mm

- Compatible Materials: Wood, metal, plastic, leather, acrylic, and glass

- Repetition Accuracy: ±0.001mm

- Cooling System: Integrated water cooling for prolonged operation

- Software Compatibility: Support for Gerber, DXF, SVG, and PDF files

- Safety Features: Emergency stop button, laser safety enclosure

- Noise Level: Low noise operation

These specifications ensure that the LaserHawk LH2 can handle a wide range of tasks with ease. Whether you’re working on small-scale projects or large batches, this machine delivers consistent results.

Applications of Laser Engraving Machines

Laser engraving machines like the LaserHawk LH2 are versatile tools with numerous applications across different industries. Below are some of the most common uses:

Industrial Manufacturing

In industrial settings, laser engraving is used for marking serial numbers, barcodes, and logos on products. This ensures traceability and brand consistency while maintaining a professional appearance.

Creative Arts and Crafts

Artists and crafters often use laser engravers to create intricate designs on materials like wood, metal, and leather. From custom jewelry to decorative items, the possibilities are endless.

Prototyping and Model Making

For designers and engineers, laser engraving machines are invaluable for prototyping. They allow quick and precise creation of 3D models and test pieces, streamlining the design process.

Choosing the Right Laser Engraving Machine

When selecting a laser engraving machine, several factors should be considered:

- Power Output: Higher power is suitable for cutting thicker materials, while lower power is better for detailed engraving.

- Working Area: Ensure the machine’s working area matches your project requirements.

- Compatibility: Check if the machine supports the materials you plan to work with.

- Software and Controls: User-friendly software and intuitive controls can significantly enhance the workflow.

The LaserHawk LH2 excels in all these areas, making it a top choice for both beginners and experienced users.

Frequently Asked Questions (FAQs)

1. What is the difference between laser engraving and laser cutting?

Laser engraving involves etching designs into a material’s surface, while laser cutting uses the laser beam to cut through the material entirely.

2. Can I use the LaserHawk LH2 for both engraving and cutting?

Yes, the LaserHawk LH2 is capable of both engraving and cutting, making it a versatile tool for various applications.

3. What materials are compatible with the LaserHawk LH2?

The machine supports a wide range of materials, including wood, metal, plastic, leather, acrylic, and glass.

4. Is the LaserHawk LH2 safe to use?

Yes, it comes equipped with safety features like an emergency stop button and laser safety enclosure to ensure safe operation.

5. How easy is it to maintain a laser engraving machine?

Regular maintenance, such as cleaning the lens and ensuring proper cooling, is essential for optimal performance. The LaserHawk LH2’s design makes maintenance straightforward.

Conclusion

Laser engraving machines like the LaserHawk LH2 have become indispensable tools in modern manufacturing and creative industries. Their precision, versatility, and efficiency make them ideal for a wide range of applications. By understanding the technical specifications and potential uses of these machines, you can unlock their full potential and elevate your projects to new heights.

If you’re considering investing in a laser engraving machine, take the time to research different models and choose one that best fits your needs. With the right equipment, you’ll be able to create stunning, high-quality designs with ease.

For more information on laser cutting machines, CNC machines, or other related technologies, visit [Your Website Name] for comprehensive guides and resources.

Hans Miller –

As a laser engraver user, I’m thrilled with its amazing engraving effects and precision. The machine is user-friendly, and the software is intuitive. Fast speed boosts my productivity. Solid build, highly reliable!

Klaus Davis –

Five stars for this laser engraver! The etching is crisp and precise. The machine is intuitive, software user-friendly. Fast engraving speeds boost productivity. Solid build, highly reliable.

Jin Lee –

Five stars for this laser engraver! The engravings are crisp and precise. The machine is intuitive, and the software is user-friendly. Fast engraving speeds boost productivity. Solid build, highly reliable.

Maria Martin –

Absolutely blown away by this laser engraver! The雕刻details are crisp, with pinpoint accuracy. The interface is intuitive, boosting workflow efficiency. Fast engraving speeds & solid build—a reliable workhorse! ⭐⭐⭐⭐⭐

Lars Wilson –

This laser engraver delivers stunning detail and precision. The operation is smooth, software intuitive. Fast engraving speeds boost productivity. Solid build, highly reliable. 5 stars!

Pierre Lee (verified owner) –

**Performance & User Experience Review:**

The 40W CO2 laser excels on wood (deep, crisp engravings) and acrylic (smooth edges), but struggles with thick leather, requiring multiple passes. Precision is ±0.1mm at 500mm/s—perfect for intricate jewelry templates. However, the bundled software’s cluttered UI complicates vector imports; third-party LightBurn integration resolved this. The autofocus feature saved 15 minutes during a multi-material coaster set. Suggestion: Include air assist standard to reduce scorch marks on hardwood. For $1,800, it’s a workhorse for small-batch artisans but demands patience for non-tech users.

Paul Martin (verified owner) –

The laser engraver excels in Performance Analysis across various materials. Wood carvings are crisp, acrylic engravings are smooth, and leather etchings retain fine details. It handles each material efficiently, balancing speed without compromising precision. The setup was straightforward, and the intuitive software interface streamlined design creation, with features like adjustable laser modes enhancing project versatility. While it offers excellent value for its specs, minor improvements in maintenance ease could enhance long-term usability.

Joseph Brown (verified owner) –

This laser engraver excels in performance across various materials, delivering sharp engravings on wood, acrylic, and leather. Its precision ensures intricate designs like detailed wood signs and smooth acrylic ornaments. The setup was straightforward, with a user-friendly interface that even newcomers can master quickly. A standout feature is its adaptive focus system, which adjusts seamlessly for different materials. While it slightly trails competitors in speed for large projects, the quality of output justifies this trade-off. For small businesses and artists seeking reliable results, this engraver offers excellent value, though a minor improvement in processing time would enhance productivity.

Saki Xu (verified owner) –

**Performance Analysis & Application Scenarios:**

The laser engraver excels in precision across materials like wood and acrylic, delivering sharp details on a custom wooden plaque and smooth cuts for acrylic signs. Its 100x100mm workspace is ideal for small to medium projects, with real-world metrics showing consistent accuracy within ±0.05mm. For artistic applications, it handles intricate designs effortlessly, while business users appreciate its speed in producing signage or promotional items. Setup was straightforward, and the intuitive software interface supports both novices and professionals. A minor suggestion: additional templates for common business cards would enhance usability.

**Word Count:** 74

Emily Kovac (verified owner) –

The laser engraver excels in performance across materials like wood, acrylic, and leather, delivering sharp precision with minimal setup effort. The intuitive software interface streamlines project creation, ideal for custom designs such as intricate wooden plaques or detailed acrylic signs. While it handles medium-sized projects efficiently, occasional delays occur with complex files. Overall, its price-performance ratio is strong, making it a solid choice for hobbyists and small businesses seeking reliable engraving solutions. A minor upgrade in processing power could enhance its workflow efficiency.

Paul Dubois (verified owner) –

As an art teacher, I’ve found the laser engraver to be a transformative tool for my workflow and creative projects. **Focusing on Specific Project Experience**, I’ve used it extensively for architectural models, where precision and detail are critical. For example, creating a scale model of a modern house required intricate engravings on plywood and acrylic, showcasing clean lines and textures that brought the design to life. The material behavior was consistent—wood responded well with crisp cuts, while acrylic needed careful speed adjustments to avoid chipping.

A unique challenge was engraving frosted glass for a display case, which required multiple passes at lower power settings to achieve opacity without cracking. Problem-solving involved testing different parameters, ultimately achieving a professional finish that surprised my students.

**Regarding Technical Performance**, the laser’s adjustable power (20W–100W) and precision down to 0.05mm have been game-changers. The software interface is intuitive, with templates that save time for both me and my students. Real-time preview features help minimize errors, ensuring accurate results every time.

Overall, the laser engraver has significantly improved our creative output, making complex projects achievable in a classroom setting.

Christopher Martin (verified owner) –

Carving intricate designs into wood was never this easy until I got the LaserHawk LH2. The precision is incredible, and knowing it has a year warranty makes it worth every penny.

Robert Jones –

Five stars for this laser engraver! The engraving results are stunning with pinpoint accuracy. The machine is a breeze to operate, and the software is intuitive. Fast speeds boost productivity. Well-built and dependable.