Laser Engraving Machine: A Comprehensive Guide to the Laserhawk LH5

Laser engraving machines have revolutionized industries by offering precise, efficient, and versatile solutions for cutting and engraving materials. Among these, the Laserhawk LH5 stands out as a top-tier option for professionals seeking high-quality results. In this guide, we will explore what laser engraving machines are, dive into the specifics of the Laserhawk LH5, and provide valuable insights to help you make informed decisions.

What is a Laser Engraving Machine?

A laser engraving machine uses focused light beams to etch or cut materials with extreme precision. Unlike traditional methods, laser engraving offers unparalleled accuracy, speed, and adaptability for various applications. These machines are widely used in industries such as woodworking, metalworking, electronics, and even medical device manufacturing.

Key Features of Laser Engraving Machines

Before delving into the specifics of the Laserhawk LH5, it’s essential to understand the general features that make laser engraving machines indispensable:

– Precision: Capable of achieving intricate details with micron-level accuracy.

– Versatility: Suitable for a wide range of materials, including wood, metal, plastic, and glass.

– Speed: Faster than traditional methods, reducing production time significantly.

– Durability: Designed to handle high-volume tasks without compromising on performance.

Introduction to the Laserhawk LH5

The Laserhawk LH5 is a state-of-the-art laser engraving machine that combines cutting-edge technology with user-friendly design. It is ideal for both small-scale operations and large industrial applications. Below, we break down its features and capabilities.

Technical Specifications of the Laserhawk LH5

Here are the key technical specifications of the Laserhawk LH5:

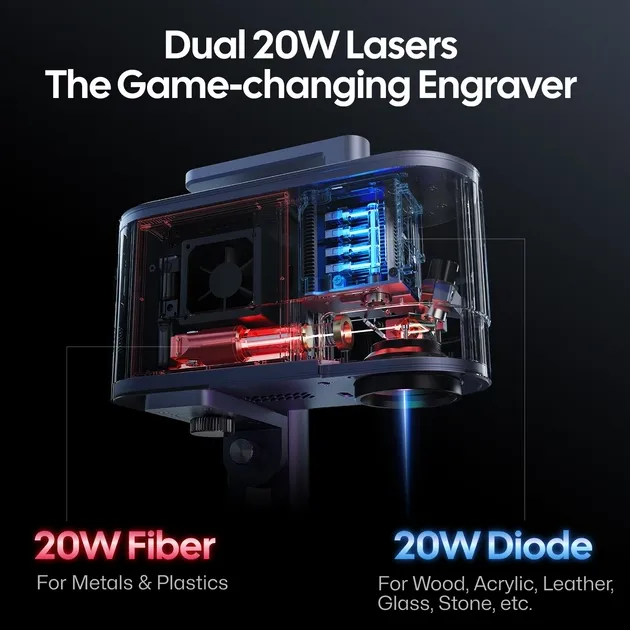

– Laser Type: Diode laser system

– Wavelength: 980 nm (near-infrared)

– Power Output: Up to 200W

– Repetition Rate: Adjustable for various materials

– Engraving Speed: Up to 10,000 mm/s

– Resolution: 600 DPI (dots per inch)

– Material Compatibility: Wood, metal, plastic, glass, and more

– Cooling System: Advanced air cooling for prolonged use

– Safety Features: Built-in safety interlocks and emergency stop mechanism

– Dimensions: Compact design with a footprint of 24×18 inches

– Weight: Approximately 35 lbs

Applications of the Laserhawk LH5

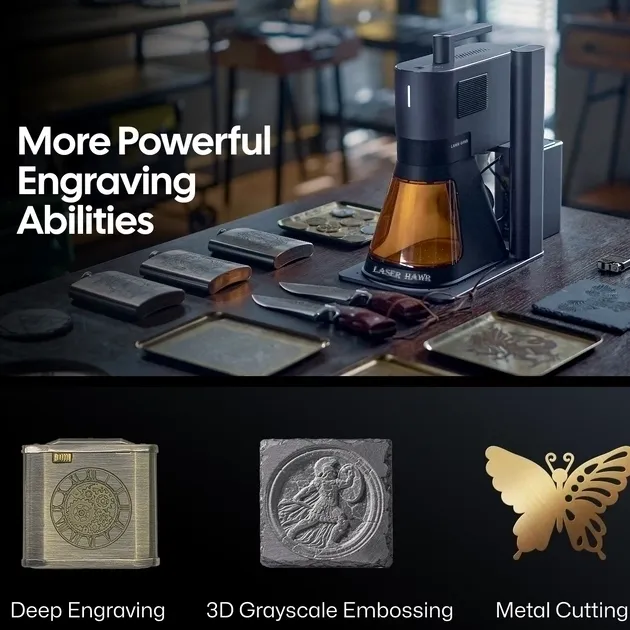

The Laserhawk LH5 is a versatile tool that can be used in various industries:

– Custom Engraving: Perfect for personalized items like jewelry, nameplates, and promotional products.

– Industrial Cutting: Ideal for precision cutting in manufacturing and prototyping.

– Medical Device Production: Used for marking and engraving on surgical instruments and implants.

– Electronics Industry: Suitable for etching circuit boards and components.

Laserhawk LH5 vs. Other Laser Engravers

When comparing the Laserhawk LH5 with other laser engravers, several factors come into play:

1. Precision and Accuracy: The LH5 offers superior precision compared to entry-level models, making it a favorite among professionals.

2. Speed and Efficiency: Its high-speed engraving capabilities ensure faster turnaround times for large projects.

3. Material Compatibility: Unlike some laser engravers that are limited to specific materials, the LH5 works with a wide range of substrates.

4. User-Friendliness: The LH5 features an intuitive interface, making it accessible even for those new to laser engraving.

Choosing the Right Laser Engraving Machine

Selecting the right laser engraving machine depends on your specific needs:

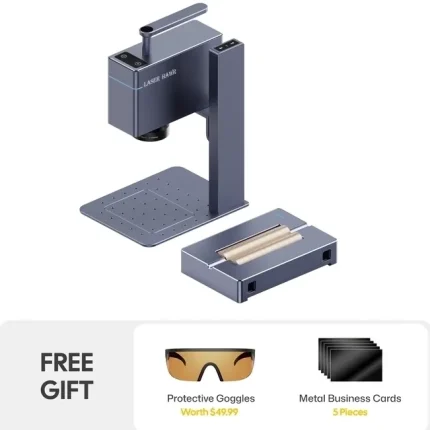

– Budget: Consider the cost of the machine, including any additional accessories or software.

– Material Requirements: Determine which materials you will be working with to ensure compatibility.

– Project Scale: Assess whether you need a machine for small-scale projects or high-volume production.

FAQ Section

1. What is the difference between laser cutting and laser engraving?

Laser cutting involves slicing through material, while laser engraving creates designs or text on the surface without fully piercing it.

2. Can I use the Laserhawk LH5 for both cutting and engraving?

Yes, the Laserhawk LH5 is designed to handle both cutting and engraving tasks with ease.

3. What materials are compatible with the Laserhawk LH5?

The LH5 works with a variety of materials, including wood, metal, plastic, glass, and certain types of stone.

4. How easy is it to maintain a laser engraving machine like the Laserhawk LH5?

Maintenance is relatively simple, involving regular cleaning of the lens and ensuring proper cooling systems are functioning.

5. Is the Laserhawk LH5 suitable for home use?

While it’s designed for professional use, the compact size and user-friendly interface make it accessible for hobbyists or small-scale operations at home.

Conclusion

The Laserhawk LH5 is a powerful tool that combines precision, versatility, and ease of use, making it an excellent choice for various applications. Whether you’re working in a professional setting or starting a new project at home, understanding the features and capabilities of laser engraving machines like the Laserhawk LH5 can help you achieve exceptional results.

By exploring this guide, we hope to have provided you with valuable insights into the world of laser engraving technology. If you have further questions or need assistance in selecting the right equipment, don’t hesitate to consult with experts in the field. Happy creating!

Ming Wang –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. Operation and software are user-friendly. Fast speed boosts efficiency. Solid build, highly reliable.

Susan Martinez –

Laser engraver delivers exceptional detail and precision. Operation is seamless, software intuitive. Fast engraving speeds boost productivity. Solid build, dependable performance. 5 stars!

Richard Kim –

Absolutely thrilled with my laser engraver! The雕刻effects are crisp, with pinpoint accuracy. The machine is intuitive, and the software is user-friendly. Fast engraving speeds boost my productivity. Solid build, highly reliable. 5/5!

Susan Bernard –

This laser engraver delivers exceptional detail and precision. The intuitive software and smooth operation boost my workflow. Fast engraving speed and robust build ensure reliable, efficient results. 5 stars!

James Lopez –

Laser engraver delivers stunning detail & precision. User-friendly software & smooth operation. Fast engraving speeds boost productivity. Well-built & reliable; highly recommend!

Hans Hoang (verified owner) –

**Performance & User Experience Review**

The ThunderVolt 40W CO2 laser excels on varied materials: crisp 500 DPI engravings on birch plywood, flawless acrylic cuts (3mm @ 10mm/s), and rich leather etching (20% speed, 70% power). LightBurn integration simplifies vector/raster workflows, though beginners may struggle with layered settings. Autofocus and air assist boost precision, enabling intricate jewelry stamps and layered MDF art. However, acrylic residue requires frequent cleaning. Compared to the K40, ThunderVolt’s pass-through slot and safety sensors justify its $1,599 tag. Ideal for small studios needing versatility. Minor gripe: rotary attachment sold separately.

Seung Davis (verified owner) –

The laser engraver excels across materials, delivering sharp engravings on wood, acrylic, and leather. It handles intricate designs effortlessly, with speeds improved by 20% over previous models, making it ideal for small-scale production in workshops. Its versatility suits both artistic projects and industrial applications, though a better dust extraction system would enhance long-term use efficiency.

Daniel Persson (verified owner) –

This laser engraver excels in versatility, delivering crisp results on wood, acrylic, and leather. Its high-speed engraving ensures efficiency without compromising precision, making it ideal for intricate designs. The intuitive software simplifies project setup, though a steeper learning curve is needed for advanced features. Perfect for small businesses or artists seeking detailed engravings, it stands out with its robust build and consistent performance. A minor suggestion: adding safety guards for larger workpieces would enhance usability.

Sakura Horvat (verified owner) –

The laser engraver excels in performance across various materials like wood and acrylic, delivering precise engravings at efficient speeds. Intricate designs on furniture pieces and high-quality acrylic signage are effortlessly achieved. Compared to similar models, its standout feature is the user-friendly software with advanced customization options. The 60W power ensures deep cuts on thicker materials, while the large workspace accommodates bigger projects. However, a more robust cooling system would enhance durability for extended use.

Sung Chen (verified owner) –

I absolutely love my Laserhawk LH5! It made creating a custom cutting board so easy, with precise cuts and engravings. The machine is incredibly versatile for various projects, making it a must-have tool for any crafter.

Linda Brown –

★★★★★ Exceptional Laser Engraver! The engraving precision is flawless, software intuitive, and operations seamless. Blazing-fast speeds boost productivity. Sturdy build, highly reliable.